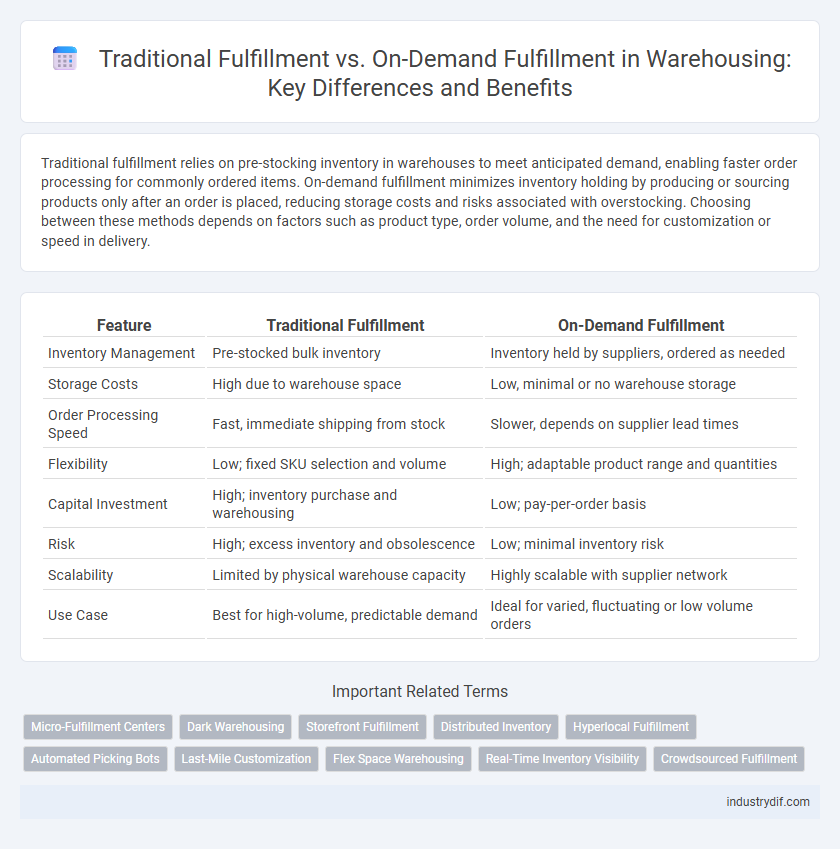

Traditional fulfillment relies on pre-stocking inventory in warehouses to meet anticipated demand, enabling faster order processing for commonly ordered items. On-demand fulfillment minimizes inventory holding by producing or sourcing products only after an order is placed, reducing storage costs and risks associated with overstocking. Choosing between these methods depends on factors such as product type, order volume, and the need for customization or speed in delivery.

Table of Comparison

| Feature | Traditional Fulfillment | On-Demand Fulfillment |

|---|---|---|

| Inventory Management | Pre-stocked bulk inventory | Inventory held by suppliers, ordered as needed |

| Storage Costs | High due to warehouse space | Low, minimal or no warehouse storage |

| Order Processing Speed | Fast, immediate shipping from stock | Slower, depends on supplier lead times |

| Flexibility | Low; fixed SKU selection and volume | High; adaptable product range and quantities |

| Capital Investment | High; inventory purchase and warehousing | Low; pay-per-order basis |

| Risk | High; excess inventory and obsolescence | Low; minimal inventory risk |

| Scalability | Limited by physical warehouse capacity | Highly scalable with supplier network |

| Use Case | Best for high-volume, predictable demand | Ideal for varied, fluctuating or low volume orders |

Overview of Traditional Fulfillment

Traditional fulfillment relies on bulk inventory stored in centralized warehouses, facilitating predictable order processing and shipping. This method supports economies of scale, reducing per-unit costs but requires significant upfront investment and storage capacity. It suits businesses with steady demand patterns and longer delivery lead times.

Defining On-Demand Fulfillment

On-demand fulfillment refers to the process of receiving, processing, and shipping orders immediately as they are placed, without relying on pre-stocked inventory. This approach leverages real-time data integration and flexible supply chain management to minimize storage costs and reduce lead times. Unlike traditional fulfillment, on-demand fulfillment enables businesses to adapt quickly to market fluctuations and customer preferences.

Key Differences Between Traditional and On-Demand Fulfillment

Traditional fulfillment relies on bulk inventory storage and pre-planned order processing, leading to higher holding costs and slower response times. On-demand fulfillment leverages real-time inventory updates and just-in-time shipping, reducing storage expenses and enabling faster delivery. The key differences include inventory management style, operational flexibility, and customer delivery speed.

Cost Structures: Traditional vs. On-Demand Fulfillment

Traditional fulfillment incurs fixed costs such as warehouse rent, labor, and inventory holding, leading to higher overhead regardless of sales volume. On-demand fulfillment reduces fixed expenses by leveraging third-party logistics and pay-as-you-go warehousing, aligning costs directly with order volume. This variable cost structure in on-demand models optimizes cash flow and minimizes risks associated with excess inventory and storage space.

Scalability and Flexibility in Fulfillment Solutions

Traditional fulfillment relies on fixed inventory storage and batch processing, limiting scalability during demand fluctuations. On-demand fulfillment leverages real-time inventory allocation and dynamic order processing to enhance flexibility and rapidly scale operations. This approach reduces overhead costs and improves responsiveness to market changes in warehousing systems.

Technology Integration in Fulfillment Models

Traditional fulfillment relies on legacy warehouse management systems (WMS) for inventory tracking and order processing, often leading to slower response times and limited real-time data visibility. On-demand fulfillment integrates advanced technologies such as AI-powered analytics, automated robotics, and cloud-based platforms to enhance scalability and accelerate order fulfillment. This technology integration enables more adaptive supply chains, reducing errors and improving customer satisfaction through faster, more accurate deliveries.

Delivery Speed and Customer Expectations

Traditional fulfillment relies on pre-stocked inventory in centralized warehouses, enabling steady delivery speeds but often resulting in longer wait times due to bulk processing and fixed shipping schedules. On-demand fulfillment leverages decentralized inventory and real-time order processing, significantly accelerating delivery by shipping products directly from closer locations or production points. Consumers now expect rapid delivery within one to two days, pressuring businesses to adopt on-demand models to meet higher speed and flexibility standards.

Inventory Management Approaches

Traditional fulfillment relies on bulk inventory storage in centralized warehouses, enabling economies of scale but requiring significant upfront investment and space management. On-demand fulfillment uses real-time inventory tracking and decentralized storage, optimizing stock levels to reduce holding costs and improve responsiveness to customer demand. Advanced inventory management software integrates with both approaches to enhance accuracy, minimize stockouts, and streamline replenishment processes.

Suitability for Different Business Types

Traditional fulfillment suits large-scale businesses with predictable demand, enabling bulk inventory storage and cost-efficient order processing. On-demand fulfillment benefits startups and small businesses by minimizing inventory costs and providing flexibility to scale with fluctuating orders. Enterprises with seasonal or variable sales often leverage a hybrid approach to balance efficiency and responsiveness across diverse market conditions.

Future Trends in Fulfillment Services

Future trends in fulfillment services indicate a shift towards increased adoption of on-demand fulfillment due to its flexibility and ability to reduce inventory costs by shipping products directly from suppliers or decentralized warehouses. Traditional fulfillment centers, while still relevant for bulk storage and predictable demand, are integrating advanced automation and AI-driven inventory management to enhance efficiency and accuracy. The rise of hybrid models combining traditional and on-demand strategies supports faster delivery times and personalized customer experiences, driven by real-time data analytics and cloud-based fulfillment platforms.

Related Important Terms

Micro-Fulfillment Centers

Micro-fulfillment centers leverage automated storage and retrieval systems to enable faster, localized order processing compared to traditional fulfillment centers that rely on larger, centralized warehouses with bulk inventory. This approach reduces last-mile delivery time and lowers operational costs by optimizing space within urban areas for on-demand fulfillment needs.

Dark Warehousing

Dark warehousing, a key component of on-demand fulfillment, eliminates the need for store-facing operations by automating inventory storage and retrieval to accelerate order processing and reduce labor costs. Traditional fulfillment relies on visible, staffed warehouses that manage bulk inventory but struggle with agility and speed, making dark warehousing essential for scalable, real-time e-commerce demands.

Storefront Fulfillment

Storefront fulfillment leverages physical retail locations as mini-warehouses, enabling faster order processing and reduced shipping costs compared to traditional fulfillment centers. This approach enhances customer experience by providing same-day or expedited delivery options through localized inventory management.

Distributed Inventory

Distributed inventory in traditional fulfillment involves storing large quantities of stock in regional warehouses to balance shipping speed and inventory costs, while on-demand fulfillment leverages decentralized micro-fulfillment centers closer to customers to reduce delivery times and enhance flexibility. This shift to distributed inventory optimizes order accuracy and scalability by dynamically allocating stock based on real-time demand patterns and geographic data.

Hyperlocal Fulfillment

Traditional fulfillment centers rely on centralized warehouses that store large inventories, resulting in longer delivery times and higher transportation costs. Hyperlocal fulfillment leverages strategically located micro-warehouses to enable rapid, same-day delivery by minimizing the distance between inventory and the end customer.

Automated Picking Bots

Automated picking bots in traditional fulfillment centers enhance efficiency by rapidly navigating fixed inventory layouts and reducing human error during order processing. In on-demand fulfillment, these robots adapt quickly to dynamic inventory changes, enabling real-time order assembly and minimizing delays in customized product delivery.

Last-Mile Customization

Traditional fulfillment centers prioritize bulk inventory storage with standardized packaging, often limiting last-mile customization options and resulting in longer delivery times. On-demand fulfillment leverages real-time order processing and flexible packaging solutions to enable personalized last-mile customization, enhancing customer experience and reducing delivery delays.

Flex Space Warehousing

Flex space warehousing bridges traditional fulfillment's fixed inventory model with on-demand fulfillment's dynamic order processing by offering scalable storage solutions that adapt to fluctuating demand. This hybrid approach optimizes warehouse utilization and reduces operational costs, enhancing supply chain responsiveness and customer satisfaction.

Real-Time Inventory Visibility

Traditional fulfillment relies on periodic inventory updates, leading to delayed visibility and potential stockouts, while on-demand fulfillment leverages real-time inventory visibility through advanced warehouse management systems, enabling accurate stock tracking and faster order processing. Real-time inventory data reduces errors, improves customer satisfaction, and optimizes supply chain responsiveness in dynamic market environments.

Crowdsourced Fulfillment

Crowdsourced fulfillment leverages a distributed network of independent workers and local businesses to store, pick, and deliver products, reducing reliance on large centralized warehouses typical of traditional fulfillment models. This approach enhances delivery speed and flexibility by tapping into regional resources while lowering inventory holding costs and expanding last-mile delivery capabilities.

Traditional Fulfillment vs On-Demand Fulfillment Infographic

industrydif.com

industrydif.com