A picking list is a traditional, paper-based or digital document that guides warehouse workers to locate items for order fulfillment, while pick-to-light is a technology-driven system using illuminated displays to direct pickers to specific locations, improving speed and accuracy. Pick-to-light reduces human error by providing real-time visual cues, whereas picking lists rely heavily on manual verification and interpretation. Implementing pick-to-light enhances productivity, especially in high-volume operations, by streamlining the picking process and reducing training time.

Table of Comparison

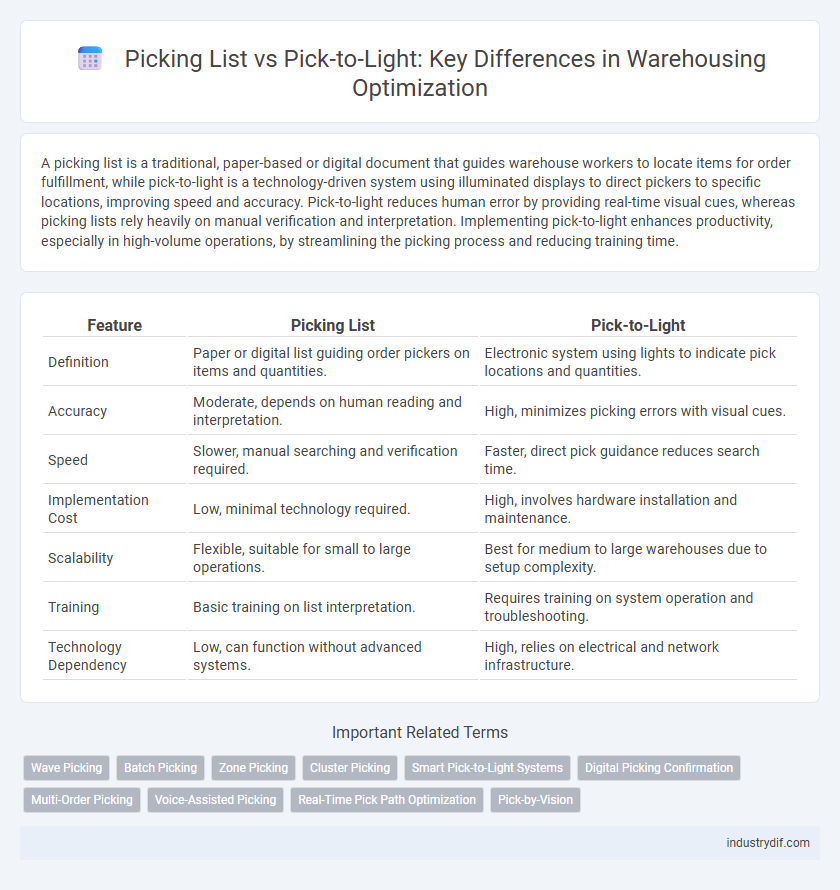

| Feature | Picking List | Pick-to-Light |

|---|---|---|

| Definition | Paper or digital list guiding order pickers on items and quantities. | Electronic system using lights to indicate pick locations and quantities. |

| Accuracy | Moderate, depends on human reading and interpretation. | High, minimizes picking errors with visual cues. |

| Speed | Slower, manual searching and verification required. | Faster, direct pick guidance reduces search time. |

| Implementation Cost | Low, minimal technology required. | High, involves hardware installation and maintenance. |

| Scalability | Flexible, suitable for small to large operations. | Best for medium to large warehouses due to setup complexity. |

| Training | Basic training on list interpretation. | Requires training on system operation and troubleshooting. |

| Technology Dependency | Low, can function without advanced systems. | High, relies on electrical and network infrastructure. |

Understanding Picking List Systems in Warehousing

Picking list systems in warehousing streamline order fulfillment by providing workers with precise item locations and quantities to retrieve, reducing errors and improving efficiency. These systems often integrate with warehouse management software, enabling real-time updates and inventory accuracy. Understanding picking list workflows is essential for optimizing labor productivity and enhancing overall warehouse operational performance.

Introduction to Pick-to-Light Technology

Pick-to-Light technology streamlines warehouse order fulfillment by guiding operators with illuminated indicators to the exact product locations, significantly reducing picking errors and increasing efficiency. Unlike traditional picking lists that rely on manual verification and paper-based instructions, Pick-to-Light systems provide real-time visual prompts, enhancing accuracy and speed in high-volume environments. This technology integrates seamlessly with warehouse management systems (WMS), optimizing workflow and inventory control for modern logistics operations.

Key Differences: Picking List vs. Pick-to-Light

Picking List relies on printed or digital lists that guide warehouse workers to specific items and quantities, making it a traditional, manual process. Pick-to-Light uses illuminated displays at each storage location to direct workers, speeding up item identification and reducing errors significantly. The main difference lies in Pick-to-Light's automation and real-time feedback, improving efficiency and accuracy compared to the more labor-intensive Picking List method.

Accuracy Comparison: Manual Picking vs. Automation

Manual picking using a picking list often results in higher error rates due to human factors like misreading or skipping items, leading to inaccuracies in order fulfillment. Pick-to-Light systems enhance accuracy by guiding workers with visual cues, reducing mistakes and improving correct item selection. Automation in pick-to-light technology typically achieves accuracy rates exceeding 99%, significantly outperforming manual picking methods.

Efficiency and Speed in Order Fulfillment

Pick-to-Light systems significantly enhance efficiency and speed in order fulfillment by reducing human errors and streamlining the picking process through real-time visual cues. Picking lists, while traditional and straightforward, rely on manual scanning and interpretation, which can slow down operations and increase the likelihood of mistakes. Implementing pick-to-light technology results in faster order processing times, higher accuracy rates, and improved overall warehouse productivity.

Integration with Warehouse Management Systems (WMS)

Picking List and Pick-to-Light systems significantly enhance Warehouse Management Systems (WMS) integration by streamlining order fulfillment processes and improving accuracy. Picking Lists provide a digital or printed guide for warehouse workers, which can be easily updated and tracked within a WMS, ensuring real-time inventory data synchronization and order status visibility. In contrast, Pick-to-Light integrates directly with WMS through electronic displays at storage locations, enabling faster, error-reduced picking by providing visual cues tied to live system data, optimizing picking efficiency and reducing training time.

Labor Costs and Training Requirements

Picking lists require workers to manually locate and pick items, leading to higher labor costs due to increased time and potential errors. Pick-to-light systems reduce labor expenses by guiding employees with visual cues, accelerating picking speed and accuracy while minimizing training needs. Although pick-to-light requires upfront investment, it significantly lowers ongoing labor costs and simplifies workforce training compared to traditional picking lists.

Scalability for High-Volume Operations

Pick-to-Light systems offer superior scalability for high-volume warehousing by automating the picking process, reducing errors, and accelerating order fulfillment compared to traditional picking lists. These systems integrate seamlessly with warehouse management software to handle increased order complexity and volume without compromising efficiency. Implementing pick-to-light technology enhances operational throughput and supports rapid scaling in large distribution centers.

Common Challenges and Error Rates

Picking lists often lead to higher error rates due to manual data entry and misinterpretation of handwritten notes, causing delays and inaccuracies in order fulfillment. Pick-to-Light systems reduce common challenges by providing real-time visual cues that guide workers to the correct items, significantly minimizing picking errors and improving speed. Despite the initial investment, Pick-to-Light technology enhances accuracy and efficiency, addressing the primary issues found in traditional picking list methods.

Choosing the Right Solution for Your Warehouse

Choosing the right picking solution for your warehouse depends on factors like order volume, accuracy requirements, and workflow complexity. Picking lists offer a cost-effective, traditional approach suitable for smaller operations with lower order frequency, while Pick-to-Light systems enhance speed and accuracy through visual cues, ideal for high-volume or complex warehouses. Evaluating the trade-offs between technology investment and operational efficiency ensures the solution aligns with your warehouse's specific needs and growth goals.

Related Important Terms

Wave Picking

Wave picking organizes orders into batches to maximize picking efficiency in large warehouses, while pick-to-light technology enhances accuracy and speed by guiding workers with illuminated displays. Combining wave picking with pick-to-light systems significantly reduces errors and increases throughput in complex order fulfillment processes.

Batch Picking

Batch picking consolidates multiple orders into a single picking session, improving efficiency by reducing travel time and increasing throughput compared to traditional picking lists. Pick-to-Light systems further enhance batch picking accuracy and speed by using illuminated indicators to guide workers directly to items, minimizing errors and boosting order fulfillment rates.

Zone Picking

Zone picking organizes warehouse inventory into specific areas, allowing workers to focus on defined zones for efficient item retrieval, while pick-to-light systems enhance accuracy by guiding pickers with illuminated indicators. Combining zone picking with pick-to-light technology optimizes order fulfillment speed and reduces errors, crucial for high-throughput warehouse operations.

Cluster Picking

Cluster picking improves warehouse efficiency by grouping multiple orders and allowing pickers to collect items simultaneously, reducing travel time compared to traditional picking lists. Integrating pick-to-light technology with cluster picking further enhances accuracy and speed by providing visual prompts for item locations and quantities.

Smart Pick-to-Light Systems

Smart Pick-to-Light systems outperform traditional picking lists by utilizing LED indicators to guide operators directly to the exact location and quantity of items, significantly reducing pick errors and enhancing speed. These systems integrate seamlessly with warehouse management software, enabling real-time inventory updates and optimized order fulfillment efficiency.

Digital Picking Confirmation

Digital Picking Confirmation enhances accuracy and efficiency in warehousing by integrating real-time data from Pick-to-Light systems, which visually guide operators to the correct items, reducing errors compared to traditional Picking Lists. This technology streamlines order fulfillment processes, enabling instant verification and tracking, which significantly improves inventory management and operational productivity.

Multi-Order Picking

Multi-order picking streamlines warehouse operations by consolidating multiple orders into a single picking session, reducing travel time and increasing efficiency compared to traditional picking lists. Pick-to-Light systems enhance accuracy and speed in multi-order environments by providing visual cues directly at storage locations, minimizing errors and boosting throughput.

Voice-Assisted Picking

Voice-assisted picking enhances accuracy and efficiency by guiding workers through picking lists using audible instructions, reducing errors compared to traditional manual methods. Unlike pick-to-light systems that rely on visual cues, voice-directed technology allows hands-free operation and is adaptable to dynamic warehouse layouts, improving overall productivity.

Real-Time Pick Path Optimization

Real-time pick path optimization in warehousing enhances efficiency by dynamically adjusting routes based on current inventory location and order priorities, significantly reducing travel time. While traditional picking lists provide static instructions, pick-to-light systems use illuminated indicators to guide workers instantly to the optimal picking location, accelerating order fulfillment and minimizing errors.

Pick-by-Vision

Pick-by-Vision technology enhances warehouse picking efficiency by using augmented reality glasses to guide workers through optimal item retrieval paths, reducing errors compared to traditional picking lists. This hands-free system outperforms Pick-to-Light by providing dynamic visual cues and real-time inventory data, improving accuracy and speed in complex fulfillment processes.

Picking List vs Pick-to-Light Infographic

industrydif.com

industrydif.com