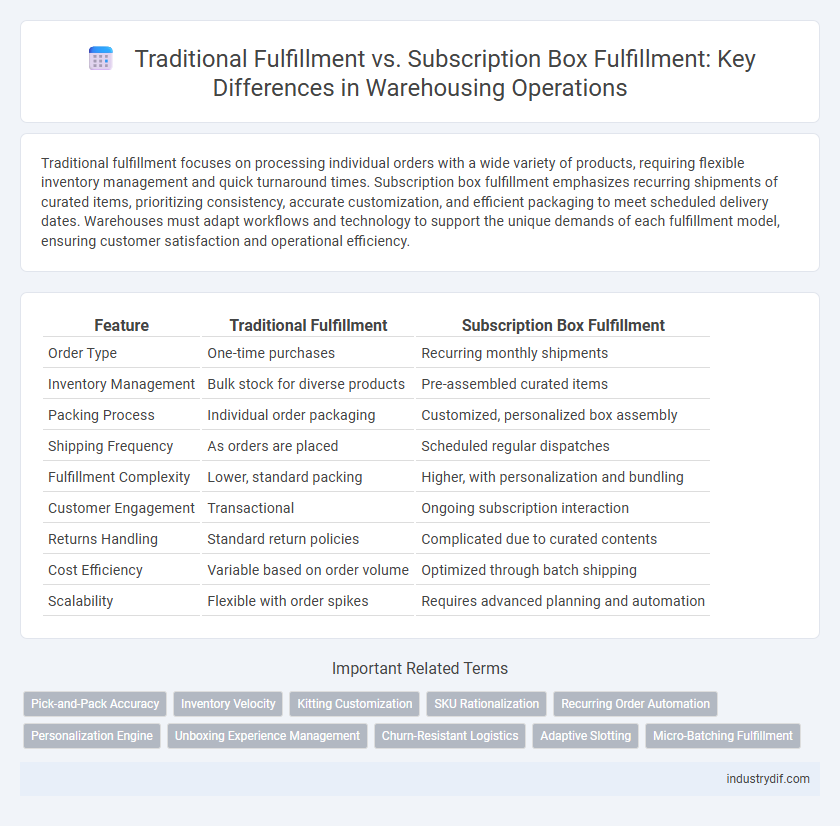

Traditional fulfillment focuses on processing individual orders with a wide variety of products, requiring flexible inventory management and quick turnaround times. Subscription box fulfillment emphasizes recurring shipments of curated items, prioritizing consistency, accurate customization, and efficient packaging to meet scheduled delivery dates. Warehouses must adapt workflows and technology to support the unique demands of each fulfillment model, ensuring customer satisfaction and operational efficiency.

Table of Comparison

| Feature | Traditional Fulfillment | Subscription Box Fulfillment |

|---|---|---|

| Order Type | One-time purchases | Recurring monthly shipments |

| Inventory Management | Bulk stock for diverse products | Pre-assembled curated items |

| Packing Process | Individual order packaging | Customized, personalized box assembly |

| Shipping Frequency | As orders are placed | Scheduled regular dispatches |

| Fulfillment Complexity | Lower, standard packing | Higher, with personalization and bundling |

| Customer Engagement | Transactional | Ongoing subscription interaction |

| Returns Handling | Standard return policies | Complicated due to curated contents |

| Cost Efficiency | Variable based on order volume | Optimized through batch shipping |

| Scalability | Flexible with order spikes | Requires advanced planning and automation |

Overview of Fulfillment Models

Traditional fulfillment focuses on processing individual customer orders with a wide variety of products shipped on demand, emphasizing speed and accuracy in single-item or bulk shipments. Subscription box fulfillment involves pre-assembling curated sets of products delivered on a recurring schedule, requiring specialized inventory management and packaging tailored to subscription cycles. Both models demand efficient warehousing systems but differ significantly in workflow, inventory forecasting, and customer engagement strategies.

Defining Traditional Fulfillment

Traditional fulfillment involves managing inventory, picking, packing, and shipping individual customer orders, typically through a centralized warehouse. This model emphasizes one-time purchases with a focus on accuracy and speed to meet consumer demand for various product types. Efficiency in traditional fulfillment relies heavily on streamlined warehouse operations and real-time inventory management systems.

What is Subscription Box Fulfillment?

Subscription box fulfillment is a specialized warehousing process where products are carefully selected, packed, and shipped on a recurring schedule to subscribers, ensuring consistency and personalization. It requires inventory management systems that handle diverse SKUs and customized packaging to enhance customer experience. Efficient subscription box fulfillment improves customer retention through timely delivery and tailored product assortments.

Inventory Management Approaches

Traditional fulfillment relies on inventory management systems optimized for high-volume, diverse product stock, focusing on real-time tracking and order accuracy to meet varied customer demands. Subscription box fulfillment emphasizes predictive inventory replenishment based on subscriber data and consistent shipment cycles, reducing storage costs and minimizing stockouts. Advanced warehouse management technologies support both models by enabling efficient space utilization and dynamic inventory allocation tailored to specific business needs.

Order Processing & Customization

Traditional fulfillment centers prioritize rapid processing of individual, diverse orders with standard packaging, focusing on efficiency and accuracy for one-time purchases. Subscription box fulfillment requires handling recurring orders with personalized curation, allowing for extensive customization of products and packaging tailored to subscriber preferences. Both models rely on robust warehouse management systems, but subscription fulfillment demands greater flexibility in inventory management and order assembly to accommodate evolving customer preferences.

Packaging and Presentation Standards

Traditional fulfillment prioritizes efficiency in packaging, using standardized boxes and protective materials to ensure product safety during shipping. Subscription box fulfillment emphasizes unique, branded packaging with customized inserts and creative presentation to enhance unboxing experiences and customer engagement. High-quality materials and attention to detail in subscription packaging contribute to increased brand loyalty and perceived value.

Shipping Workflows and Logistics

Traditional fulfillment relies on bulk order processing and standardized shipping workflows, optimizing for large volumes with predictable destinations. Subscription box fulfillment requires tailored logistics that handle smaller, recurring shipments with personalized packaging and flexible delivery schedules. Efficient inventory management and real-time tracking are critical in subscription workflows to maintain consistency and customer satisfaction.

Technology Integration in Fulfillment

Traditional fulfillment relies on legacy warehouse management systems (WMS) that prioritize accuracy and speed for one-time orders, whereas subscription box fulfillment leverages advanced automation and integrated platforms to handle recurring, personalized shipments efficiently. Subscription services utilize AI-driven demand forecasting and inventory optimization tools to manage fluctuating subscriber preferences, reducing stockouts and waste. Enhanced API connectivity in subscription models allows real-time synchronization between customer data, inventory, and shipping carriers, streamlining the end-to-end fulfillment process.

Cost Structures and Pricing Models

Traditional fulfillment typically involves variable costs based on order volume, including pick-and-pack fees, storage charges, and shipping expenses, making it suitable for businesses with irregular orders. Subscription box fulfillment often relies on fixed monthly fees combined with predictable per-box packing and shipping costs, optimizing budgeting for recurring shipments and bulk procurement discounts. Pricing models in subscription fulfillment emphasize scale and consistency, which reduce per-unit costs compared to the often fluctuating expenses in traditional fulfillment setups.

Scalability and Growth Potential

Traditional fulfillment systems often face scalability constraints due to the variability in order volumes and customization demands, limiting growth potential. Subscription box fulfillment leverages predictable, recurring orders, enhancing operational efficiency and enabling streamlined inventory management. This reliability supports scalable growth by reducing fulfillment errors and optimizing resource allocation.

Related Important Terms

Pick-and-Pack Accuracy

Traditional fulfillment centers achieve high pick-and-pack accuracy by processing individual orders with standardized SKU handling and barcode scanning systems. Subscription box fulfillment demands even greater precision due to complex multi-item assortments per box, requiring advanced inventory management and quality control measures to minimize errors and ensure consistent customer satisfaction.

Inventory Velocity

Traditional fulfillment relies on inventory velocity driven by sporadic, high-volume orders causing variable turnover rates, while subscription box fulfillment achieves consistent inventory velocity through scheduled, predictable shipments, ensuring steady stock rotation and optimized warehouse space utilization. Efficient inventory management in subscription models reduces holding costs and minimizes stockouts compared to traditional fulfillment's fluctuating demand patterns.

Kitting Customization

Traditional fulfillment often involves standard packaging and bulk shipping, limiting opportunities for product kitting and customization, whereas subscription box fulfillment excels in assembling personalized kits tailored to individual customer preferences. This specialization requires advanced inventory management systems and precise pick-and-pack processes to ensure accuracy and enhance customer satisfaction in subscription-based models.

SKU Rationalization

Traditional fulfillment requires managing a wide range of SKUs to accommodate diverse customer orders, which can complicate inventory control and increase storage costs. Subscription box fulfillment benefits from SKU rationalization by streamlining product assortments, reducing inventory variability, and improving order accuracy and warehouse efficiency.

Recurring Order Automation

Traditional fulfillment relies on manual order processing for each purchase, often leading to delays and errors, while subscription box fulfillment uses recurring order automation to streamline inventory management and ensure timely deliveries, enhancing customer retention and operational efficiency. Automated systems in subscription box fulfillment predict demand, optimize stock levels, and reduce fulfillment costs by minimizing human intervention in repetitive tasks.

Personalization Engine

Traditional fulfillment relies on standardized order processing, while subscription box fulfillment integrates advanced personalization engines to curate tailored product selections based on customer preferences and behavior. These personalization engines leverage data analytics and machine learning to optimize inventory allocation and enhance customer satisfaction through individualized experiences.

Unboxing Experience Management

Traditional fulfillment prioritizes speed and accuracy in processing individual orders, often resulting in minimal personalization of packaging and unboxing experiences. Subscription box fulfillment emphasizes curated, branded presentations with customized packaging and inserts to enhance customer engagement and foster brand loyalty through a memorable unboxing journey.

Churn-Resistant Logistics

Traditional fulfillment relies on one-time order processing with variable shipping volumes, creating challenges in inventory predictability and labor allocation. Subscription box fulfillment utilizes churn-resistant logistics by streamlining repetitive packaging and shipment cycles, optimizing inventory turnover, and reducing operational costs through predictable demand patterns.

Adaptive Slotting

Adaptive slotting in traditional fulfillment centers optimizes inventory storage by dynamically reallocating SKU locations based on order frequency and seasonal demand patterns, enhancing pick efficiency and reducing labor costs. In contrast, subscription box fulfillment requires more flexible slotting systems to accommodate diverse, varying product assortments and frequent replenishments, ensuring timely, accurate order assembly and maintaining customer satisfaction.

Micro-Batching Fulfillment

Micro-batching fulfillment in warehousing enhances efficiency by processing smaller, frequent orders typical of subscription boxes, contrasting with traditional fulfillment's bulk order approach. This method reduces inventory holding costs and accelerates turnaround times, optimizing supply chain responsiveness for recurring, personalized shipments.

Traditional Fulfillment vs Subscription Box Fulfillment Infographic

industrydif.com

industrydif.com