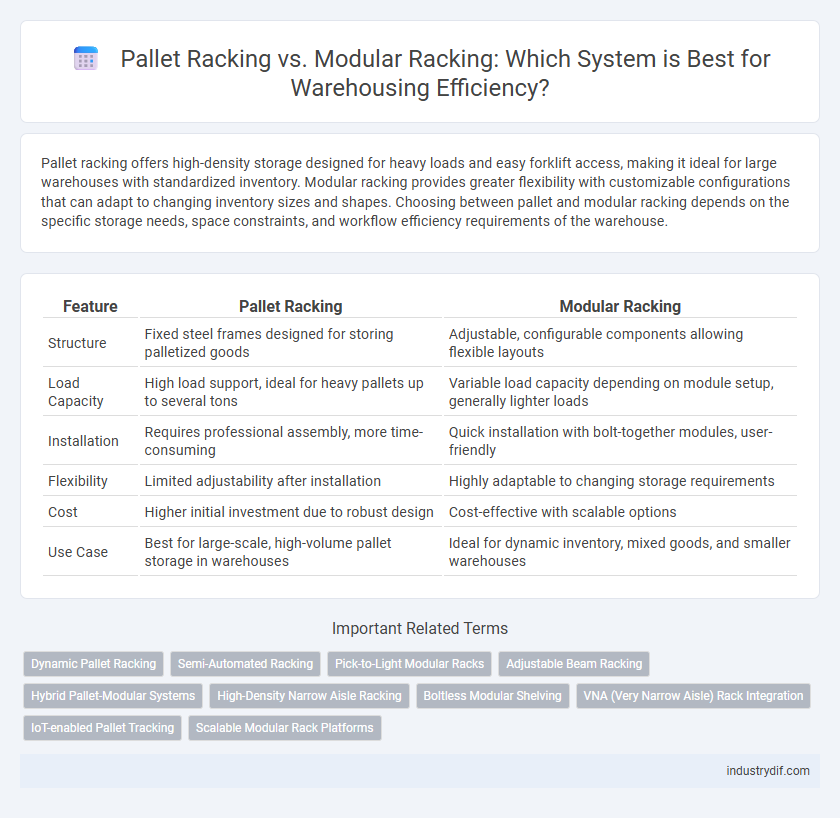

Pallet racking offers high-density storage designed for heavy loads and easy forklift access, making it ideal for large warehouses with standardized inventory. Modular racking provides greater flexibility with customizable configurations that can adapt to changing inventory sizes and shapes. Choosing between pallet and modular racking depends on the specific storage needs, space constraints, and workflow efficiency requirements of the warehouse.

Table of Comparison

| Feature | Pallet Racking | Modular Racking |

|---|---|---|

| Structure | Fixed steel frames designed for storing palletized goods | Adjustable, configurable components allowing flexible layouts |

| Load Capacity | High load support, ideal for heavy pallets up to several tons | Variable load capacity depending on module setup, generally lighter loads |

| Installation | Requires professional assembly, more time-consuming | Quick installation with bolt-together modules, user-friendly |

| Flexibility | Limited adjustability after installation | Highly adaptable to changing storage requirements |

| Cost | Higher initial investment due to robust design | Cost-effective with scalable options |

| Use Case | Best for large-scale, high-volume pallet storage in warehouses | Ideal for dynamic inventory, mixed goods, and smaller warehouses |

Introduction to Warehouse Storage Systems

Pallet racking systems provide efficient vertical storage by stacking pallets on sturdy, steel frames to maximize warehouse space and facilitate easy access with forklifts. Modular racking offers customizable configurations that adapt to various storage needs, allowing seamless scalability and flexibility for different product sizes and inventory changes. Both systems optimize warehouse organization and inventory management but differ in adaptability and design complexity suited to diverse operational requirements.

Overview of Pallet Racking

Pallet racking is a widely used storage solution in warehouses designed to store palletized goods efficiently, maximizing vertical space and improving inventory organization. This system supports heavy loads with steel frames and beams arranged in rows, allowing easy access with forklifts for streamlined loading and unloading processes. Compared to modular racking, pallet racking offers higher load capacity and better durability for large-scale warehousing environments with heavy pallet throughput.

Overview of Modular Racking

Modular racking offers a highly customizable storage solution designed to adapt to various warehouse configurations, optimizing space utilization and accessibility. Its interchangeable components allow quick reassembly and reconfiguration, reducing downtime during layout changes. Compared to traditional pallet racking, modular racking supports diverse load types and sizes, enhancing flexibility for dynamic inventory management.

Key Differences Between Pallet and Modular Racking

Pallet racking is designed primarily for storing palletized goods in a fixed, dense configuration, optimizing space for bulk storage and easy forklift access. Modular racking offers flexible and customizable storage solutions, allowing for adjustable shelves and configurations to accommodate various item sizes and shapes. Key differences include load capacity, adaptability, and the type of inventory handled, with pallet racking suited for heavy, uniform loads and modular racking ideal for diverse, smaller items.

Load Capacity Comparison

Pallet racking systems typically offer higher load capacities, supporting weights up to 5,000 pounds per beam, making them ideal for heavy-duty storage in warehouses. Modular racking, while more versatile and customizable, generally supports lower load capacities, often ranging between 1,500 to 3,000 pounds per section. Selecting the appropriate system depends on the warehouse's specific load requirements and the types of goods being stored.

Space Optimization Techniques

Pallet racking maximizes vertical storage by utilizing standardized pallets, allowing for high-density stacking and easy access in warehouses with large inventory volumes. Modular racking offers flexible configurations that adapt to varying load sizes and shapes, optimizing unused space through customizable shelving layouts. Both systems enhance warehouse efficiency by reducing aisle widths and increasing storage capacity, but modular racking excels in environments requiring frequent adjustments and diverse product storage.

Flexibility and Scalability

Pallet racking systems offer robust storage solutions designed for heavy loads and standardized pallet sizes, ensuring efficient space utilization and easy access. Modular racking provides superior flexibility with customizable configurations that adapt to changing inventory sizes and storage requirements, supporting rapid scalability. Businesses seeking dynamic storage expansion benefit from modular racking's ability to reconfigure without major infrastructure changes, unlike traditional pallet racking systems.

Cost Implications and ROI

Pallet racking systems generally offer lower upfront costs and faster installation, making them ideal for warehouses with stable inventory and long-term storage needs. Modular racking, though initially more expensive due to its flexible components and adaptability, can enhance ROI by accommodating dynamic inventory levels and reducing future modification expenses. Evaluating warehouse layout, inventory turnover rates, and scalability requirements is crucial for optimizing cost efficiency and maximizing return on investment.

Safety and Maintenance Considerations

Pallet racking systems require regular inspections to ensure load-bearing components, such as beams and uprights, remain undamaged to prevent collapse, while modular racking offers enhanced safety through customizable configurations that adapt to warehouse layout changes, reducing overloading risks. Maintenance of pallet racking often involves bolt tightening and replacement of damaged parts, whereas modular racking benefits from easier component swaps and minimal downtime due to its flexible assembly design. Safety standards like OSHA and ANSI emphasize the importance of proper installation and ongoing maintenance for both systems to ensure worker safety and operational efficiency.

Choosing the Right Racking System for Your Warehouse

Pallet racking offers high-density storage designed for heavy loads, ideal for warehouses with fast-moving inventory and forklift access. Modular racking provides flexibility and adaptability, allowing easy reconfiguration to accommodate changing storage needs and various product sizes. Selecting the right system depends on space optimization, load capacity, and inventory turnover rate to maximize warehouse efficiency.

Related Important Terms

Dynamic Pallet Racking

Dynamic pallet racking systems maximize storage efficiency through gravity-fed rollers that enable first-in, first-out inventory management, reducing handling time compared to static pallet racking. Modular racking offers flexibility with adjustable components but lacks the high throughput and space optimization of dynamic pallet racks designed for fast-moving goods.

Semi-Automated Racking

Semi-automated pallet racking systems enhance warehouse efficiency by combining traditional pallet storage with mechanized retrieval, optimizing space and speed for bulk inventory handling. Modular racking systems in semi-automated settings offer customizable configurations and scalability, allowing dynamic adaptation to varying load sizes and warehouse layouts while integrating automated stacker cranes or conveyors.

Pick-to-Light Modular Racks

Pick-to-Light modular racks enhance warehouse efficiency by providing real-time visual picking cues, significantly reducing picking errors and increasing speed compared to traditional pallet racking systems. These racks integrate LED indicators directly at the storage locations, optimizing order fulfillment processes for high-volume, SKU-dense environments.

Adjustable Beam Racking

Adjustable beam racking offers customizable storage heights, making it ideal for warehouses requiring flexibility in pallet stacking compared to modular racking's fixed configuration. This type of pallet racking enhances space utilization and operational efficiency by allowing quick adjustments to accommodate varying load sizes and inventory turnover.

Hybrid Pallet-Modular Systems

Hybrid pallet-modular racking systems combine the high-density storage capabilities of pallet racking with the flexibility and adaptability of modular racking, optimizing space utilization in warehouses. This integration supports varied inventory types and improves accessibility, enhancing operational efficiency and storage scalability.

High-Density Narrow Aisle Racking

High-density narrow aisle racking maximizes storage capacity by utilizing pallet racking systems designed for close aisle configurations, offering enhanced space efficiency compared to modular racking. Pallet racking systems support higher load capacities and faster accessibility, making them ideal for warehouses prioritizing operational throughput over the flexibility of modular designs.

Boltless Modular Shelving

Boltless modular shelving offers superior flexibility and ease of installation compared to traditional pallet racking, making it ideal for dynamic warehousing environments with frequently changing storage needs. Its boltless design reduces assembly time and maintenance, while providing adjustable shelving options that optimize space utilization and improve inventory accessibility.

VNA (Very Narrow Aisle) Rack Integration

VNA pallet racking systems maximize vertical storage density by enabling forklift operation in aisles as narrow as 1.4 meters, whereas modular racking offers customizable configurations for varied warehouse layouts but may sacrifice aisle width flexibility. Integrating VNA rack technology with modular racking designs enhances space utilization and operational efficiency in high-density warehousing environments.

IoT-enabled Pallet Tracking

IoT-enabled pallet tracking in pallet racking systems enhances warehouse efficiency by providing real-time inventory visibility and automated location identification, reducing errors and improving throughput. Unlike modular racking, which offers flexible storage configurations, pallet racking integrated with IoT sensors enables precise monitoring of pallet movements and condition, optimizing space utilization and streamlining supply chain management.

Scalable Modular Rack Platforms

Scalable modular rack platforms offer enhanced flexibility and easy customization compared to traditional pallet racking systems, enabling warehouses to quickly adapt storage configurations to varying inventory sizes and shapes. Utilizing modular components allows for efficient space optimization and simplified reconfiguration without extensive downtime, improving overall warehouse operational efficiency.

Pallet Racking vs Modular Racking Infographic

industrydif.com

industrydif.com