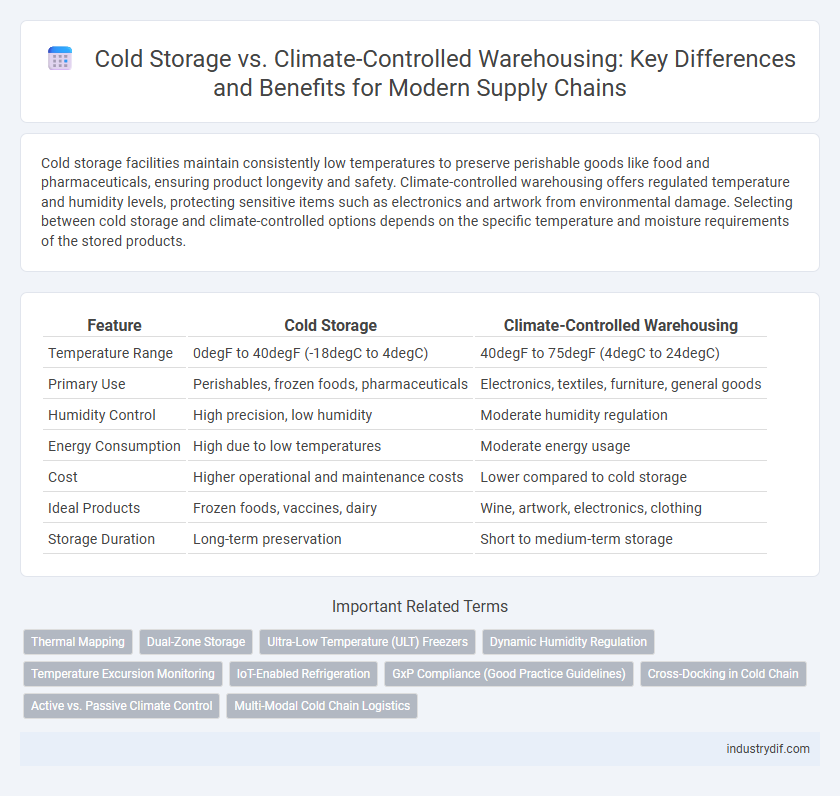

Cold storage facilities maintain consistently low temperatures to preserve perishable goods like food and pharmaceuticals, ensuring product longevity and safety. Climate-controlled warehousing offers regulated temperature and humidity levels, protecting sensitive items such as electronics and artwork from environmental damage. Selecting between cold storage and climate-controlled options depends on the specific temperature and moisture requirements of the stored products.

Table of Comparison

| Feature | Cold Storage | Climate-Controlled Warehousing |

|---|---|---|

| Temperature Range | 0degF to 40degF (-18degC to 4degC) | 40degF to 75degF (4degC to 24degC) |

| Primary Use | Perishables, frozen foods, pharmaceuticals | Electronics, textiles, furniture, general goods |

| Humidity Control | High precision, low humidity | Moderate humidity regulation |

| Energy Consumption | High due to low temperatures | Moderate energy usage |

| Cost | Higher operational and maintenance costs | Lower compared to cold storage |

| Ideal Products | Frozen foods, vaccines, dairy | Wine, artwork, electronics, clothing |

| Storage Duration | Long-term preservation | Short to medium-term storage |

Introduction to Cold Storage and Climate-Controlled Warehousing

Cold storage warehouses maintain temperatures below freezing to preserve perishable goods like frozen foods, pharmaceuticals, and certain chemicals, ensuring extended shelf life and product integrity. Climate-controlled warehouses regulate temperature and humidity without freezing, ideal for items such as fresh produce, electronics, and textiles that require stable environmental conditions to prevent spoilage or damage. Both warehousing types are critical in supply chain management to optimize storage conditions, reduce waste, and maintain product quality across various industries.

Key Differences Between Cold Storage and Climate-Controlled Warehousing

Cold storage facilities maintain temperatures below 32degF to preserve perishable goods such as frozen foods and pharmaceuticals, ensuring optimal shelf life through strict freezing conditions. Climate-controlled warehousing regulates temperature and humidity levels between 50degF and 77degF, protecting items sensitive to moisture and temperature fluctuations like electronics, artwork, and certain organic products. The key difference lies in their temperature ranges and target inventory protection, with cold storage focusing on freezing preservation while climate-controlled warehouses offer a balanced environment for temperature-sensitive but non-frozen goods.

Core Functions of Cold Storage Facilities

Cold storage facilities specialize in maintaining consistently low temperatures to preserve perishable goods such as food, pharmaceuticals, and chemicals, preventing spoilage and extending shelf life. These warehouses utilize refrigeration systems, insulated walls, and humidity controls to create an environment ideal for frozen or chilled products. Core functions include temperature monitoring, rapid inventory turnover, and compliance with safety regulations to ensure product quality and traceability throughout the supply chain.

How Climate-Controlled Warehouses Maintain Product Integrity

Climate-controlled warehouses maintain product integrity by regulating temperature and humidity levels to create an optimal environment for sensitive goods, such as pharmaceuticals, electronics, and perishable foods. These facilities use advanced HVAC systems, real-time monitoring, and automated controls to prevent deterioration, mold growth, and spoilage. Unlike cold storage, which primarily focuses on freezing or chilling, climate-controlled warehousing provides precise conditions tailored to the specific needs of diverse inventory, ensuring longer shelf life and consistent quality.

Types of Products Requiring Cold Storage vs Climate Control

Cold storage warehouses are designed to maintain temperatures below freezing, ideal for perishable products such as frozen foods, pharmaceuticals, and biological samples requiring strict temperature preservation. Climate-controlled warehouses regulate temperature and humidity levels without freezing, suitable for items like electronics, artwork, wine, and cosmetics that are sensitive to moisture and temperature fluctuations. Selecting the appropriate warehousing depends on the specific thermal stability and preservation needs of the stored products.

Energy Efficiency and Sustainability Considerations

Cold storage warehouses use advanced refrigeration systems to maintain temperatures below freezing, resulting in high energy consumption but critical for preserving perishable goods. Climate-controlled warehouses regulate temperature and humidity within set ranges above freezing, optimizing energy use by employing insulated designs and HVAC systems tailored to specific product needs. Implementing energy-efficient technologies such as variable-speed compressors, LED lighting, and solar power integration enhances sustainability in both warehousing types, reducing carbon footprints and operating costs.

Compliance and Regulatory Requirements

Cold storage facilities must strictly adhere to FDA and USDA regulations for temperature-sensitive products, ensuring continuous temperature monitoring and validation to maintain product safety and quality. Climate-controlled warehousing involves compliance with OSHA and EPA guidelines, focusing on maintaining humidity and temperature within specific ranges to prevent product degradation and meet industry standards. Both types of warehousing require extensive documentation and routine inspections to satisfy regulatory agencies and support traceability.

Cost Factors: Cold Storage vs Climate-Controlled Warehousing

Cold storage facilities require significantly higher energy consumption due to the need to maintain sub-freezing temperatures, resulting in increased operational costs compared to climate-controlled warehouses. Climate-controlled warehousing, which manages temperature and humidity within a moderate range, offers lower utility expenses but may involve higher initial setup costs due to advanced HVAC systems. Evaluating these cost factors is essential for businesses to select storage solutions that balance budget constraints with product preservation requirements.

Technological Innovations in Temperature-Sensitive Warehousing

Advancements in temperature-sensitive warehousing integrate IoT sensors and AI-driven climate control systems to optimize cold storage environments, maintaining consistent temperatures for perishable goods. Remote monitoring technologies enable real-time data analytics, reducing spoilage risks and enhancing inventory management efficiency. Automated refrigeration units combined with predictive maintenance algorithms significantly lower energy consumption while preserving product integrity in climate-controlled warehouses.

Choosing the Right Warehousing Solution for Your Business

Cold storage warehouses maintain temperatures below freezing, ideal for perishable goods like frozen foods and pharmaceuticals, ensuring extended shelf life and strict hygiene standards. Climate-controlled warehousing offers precise temperature and humidity regulation, suitable for sensitive items such as electronics, artworks, and fresh produce, preventing damage due to environmental fluctuations. Selecting the right warehousing solution depends on the nature of your inventory, storage duration, and required environmental specifications to optimize product quality and reduce operational costs.

Related Important Terms

Thermal Mapping

Thermal mapping in cold storage facilities ensures precise temperature monitoring to maintain frozen goods at consistent sub-zero levels, preventing spoilage and extending shelf life. Climate-controlled warehousing employs thermal mapping to regulate humidity and temperature variances, optimizing conditions for sensitive products like pharmaceuticals and electronics.

Dual-Zone Storage

Dual-zone storage in warehousing combines cold storage and climate-controlled environments within a single facility, enabling precise temperature regulation for diverse products such as pharmaceuticals, perishable foods, and sensitive electronics. This integrated approach enhances inventory management by maintaining optimal conditions in separate zones, reducing energy costs and minimizing product spoilage.

Ultra-Low Temperature (ULT) Freezers

Ultra-low temperature (ULT) freezers in cold storage facilities maintain temperatures as low as -80degC to preserve sensitive pharmaceuticals, biological samples, and specialty food products, ensuring optimal longevity and stability. Climate-controlled warehousing typically ranges from 15degC to 25degC with regulated humidity, suitable for less temperature-sensitive inventory while ULT freezers provide critical ultra-low temperature environments required for extreme preservation needs.

Dynamic Humidity Regulation

Cold storage facilities maintain low temperatures primarily for preserving perishable goods, while climate-controlled warehousing offers dynamic humidity regulation to optimize storage conditions for sensitive products such as electronics, pharmaceuticals, and textiles. Advanced humidity control systems in climate-controlled warehouses prevent mold growth, corrosion, and moisture-related damage, ensuring product integrity throughout the supply chain.

Temperature Excursion Monitoring

Temperature excursion monitoring in cold storage facilities ensures perishable goods remain within strict temperature ranges, preventing spoilage and maintaining product integrity. Climate-controlled warehousing incorporates advanced sensors and real-time monitoring systems to detect and address temperature fluctuations promptly, optimizing storage conditions for temperature-sensitive products beyond just cold environments.

IoT-Enabled Refrigeration

IoT-enabled refrigeration in cold storage warehouses enables real-time temperature monitoring and predictive maintenance, ensuring optimal preservation of perishable goods and reducing energy consumption. Climate-controlled warehousing leverages IoT sensors to maintain precise humidity and temperature levels tailored for sensitive products, enhancing inventory quality and operational efficiency.

GxP Compliance (Good Practice Guidelines)

Cold storage warehouses maintain precise low temperatures essential for GxP compliance in pharmaceutical and biotech industries, ensuring product stability and preventing degradation during storage. Climate-controlled warehousing regulates temperature and humidity within specific ranges to meet GxP standards for sensitive products, protecting against contamination and preserving efficacy throughout the supply chain.

Cross-Docking in Cold Chain

Cold storage facilities maintain temperatures below freezing to preserve perishable goods, making them essential for cross-docking operations in the cold chain that demand rapid transfer without compromising product integrity. Climate-controlled warehousing offers regulated environmental conditions like humidity and temperature control above freezing, supporting broader product types but less suited for the immediate cross-docking needs of frozen goods.

Active vs. Passive Climate Control

Cold storage warehouses utilize active climate control systems with refrigeration units maintaining precise low temperatures, essential for perishable goods like seafood and pharmaceuticals. Climate-controlled warehouses rely on passive methods such as insulation and humidity regulators to stabilize conditions, suitable for items sensitive to temperature fluctuations but not requiring constant cooling.

Multi-Modal Cold Chain Logistics

Multi-modal cold chain logistics integrates cold storage and climate-controlled warehousing to maintain precise temperature conditions across transportation modes, ensuring product integrity and extended shelf life for perishable goods. Advanced sensor technologies and real-time monitoring are critical for optimizing temperature-sensitive supply chains and minimizing spoilage risks.

Cold Storage vs Climate-Controlled Warehousing Infographic

industrydif.com

industrydif.com