Palletization optimizes storage by stacking goods on pallets for efficient handling and transportation within warehouses, improving load stability and space utilization. Automated Mobile Robots (AMRs) enhance flexibility in material movement by navigating dynamically through warehouse layouts without fixed paths, reducing labor costs and increasing throughput. Combining palletization with AMR handling creates a synergistic effect, maximizing operational efficiency and adaptability in modern warehousing environments.

Table of Comparison

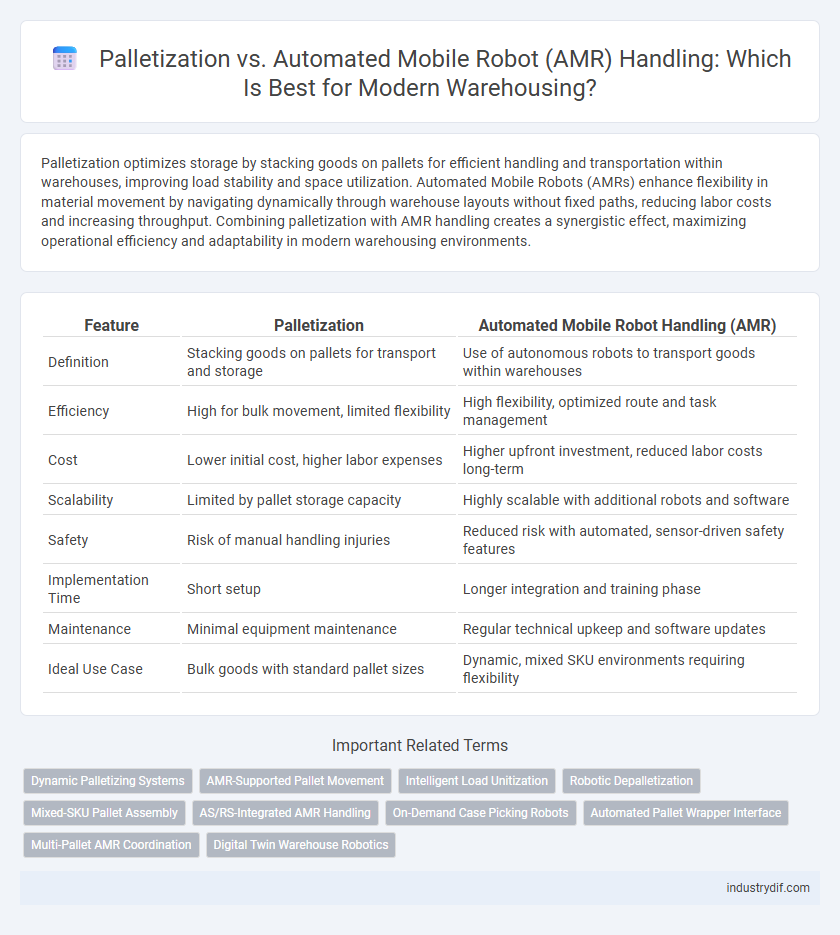

| Feature | Palletization | Automated Mobile Robot Handling (AMR) |

|---|---|---|

| Definition | Stacking goods on pallets for transport and storage | Use of autonomous robots to transport goods within warehouses |

| Efficiency | High for bulk movement, limited flexibility | High flexibility, optimized route and task management |

| Cost | Lower initial cost, higher labor expenses | Higher upfront investment, reduced labor costs long-term |

| Scalability | Limited by pallet storage capacity | Highly scalable with additional robots and software |

| Safety | Risk of manual handling injuries | Reduced risk with automated, sensor-driven safety features |

| Implementation Time | Short setup | Longer integration and training phase |

| Maintenance | Minimal equipment maintenance | Regular technical upkeep and software updates |

| Ideal Use Case | Bulk goods with standard pallet sizes | Dynamic, mixed SKU environments requiring flexibility |

Introduction to Palletization and Automated Mobile Robot (AMR) Handling

Palletization involves stacking and securing goods on pallets for efficient storage and transport, optimizing space utilization and simplifying inventory management in warehouses. Automated Mobile Robot (AMR) handling uses robotic systems capable of navigating warehouse floors autonomously to move goods, enhancing flexibility and reducing labor costs. Integrating palletization with AMR technology streamlines warehouse operations by combining stable load consolidation with intelligent, adaptive material handling.

Defining Palletization in Modern Warehousing

Palletization in modern warehousing involves organizing goods on pallets for efficient storage, handling, and transport, enhancing space utilization and inventory management. This method streamlines loading and unloading processes, reduces product damage, and supports compatibility with automated systems. Palletization remains a foundational practice for integrating Automated Mobile Robots (AMRs) that rely on standardized pallet sizes and stable loads for optimized navigation and material movement.

The Evolution of Automated Mobile Robot Handling

Automated Mobile Robot (AMR) handling has revolutionized warehousing by enhancing flexibility and efficiency compared to traditional palletization methods. AMRs utilize advanced navigation and AI algorithms to dynamically transport goods, reducing manual labor and optimizing space utilization. The evolution of AMRs includes integration with warehouse management systems (WMS) and real-time data analytics, enabling seamless inventory movement and improved operational throughput.

Key Differences Between Palletization and AMR Handling

Palletization involves stacking goods on pallets for manual or forklift transport, emphasizing standardized load units and warehouse space optimization. Automated Mobile Robots (AMRs) use advanced navigation and sensors to autonomously move items throughout the facility, enhancing flexibility and real-time route optimization. Key differences include palletization's reliance on fixed infrastructure and manual intervention versus AMR's autonomous mobility and dynamic adaptability to changing warehouse layouts.

Efficiency and Productivity: Palletization vs AMR Handling

Palletization enhances warehouse efficiency by streamlining the stacking and storage of goods, reducing manual labor and minimizing errors in order fulfillment. Automated Mobile Robots (AMRs) boost productivity by dynamically navigating warehouses to transport pallets and items, ensuring faster throughput and real-time inventory management. Integrating AMRs with palletized systems maximizes operational agility, reduces downtime, and accelerates material flow within distribution centers.

Cost Analysis: Initial Investment and Long-Term ROI

Palletization requires a lower initial investment compared to Automated Mobile Robot (AMR) handling, making it cost-effective for small to medium warehouses with limited budgets. However, AMR systems offer higher long-term return on investment through increased operational efficiency, reduced labor costs, and enhanced scalability in large-scale warehouses. Cost analysis reveals that warehouses with high throughput and complex inventory benefit financially from AMR's automation despite higher upfront expenses.

Safety Considerations in Both Warehousing Approaches

Palletization typically involves stacked goods secured on pallets, reducing manual handling but requiring careful inspection for load stability to prevent workplace accidents. Automated Mobile Robots (AMRs) enhance safety by minimizing human contact with heavy loads and hazardous zones, using sensors and AI to navigate obstacles and avoid collisions. Both approaches demand rigorous safety protocols, but AMRs offer superior operational monitoring and adaptability in dynamic warehouse environments.

Scalability and Flexibility in Dynamic Warehouse Environments

Palletization offers reliable scalability by allowing warehouses to stack and manage goods efficiently on standardized pallets, supporting high-volume storage and straightforward inventory control. Automated Mobile Robot (AMR) handling enhances flexibility through dynamic navigation and adaptable task allocation, enabling real-time response to shifting warehouse layouts and variable order patterns. Combining palletization with AMR technology maximizes operational scalability and flexibility, addressing the complex demands of modern, dynamic warehouse environments.

Integration Challenges and Solutions

Palletization requires precise stacking patterns and standardized pallet sizes, which can complicate integration with Automated Mobile Robot (AMR) handling systems due to variability in load dimensions and weights. Solutions include implementing advanced sensor fusion and AI-driven path planning to enable AMRs to adapt dynamically to diverse pallet configurations while maintaining efficiency and safety. Integrating warehouse management systems (WMS) with AMR control software ensures real-time coordination, reducing bottlenecks and enhancing overall operational flow.

Future Trends in Warehousing Automation

Palletization remains integral for bulk storage and streamlined loading processes, but Automated Mobile Robot (AMR) handling is rapidly advancing, driving higher flexibility and efficiency in warehousing operations. Future trends emphasize the increasing adoption of AMRs equipped with AI and machine learning algorithms to optimize route planning, reduce labor costs, and enhance real-time inventory management. Integration of AMRs with IoT devices and warehouse management systems (WMS) will further revolutionize automation by enabling predictive analytics and dynamic task allocation.

Related Important Terms

Dynamic Palletizing Systems

Dynamic palletizing systems enhance warehouse efficiency by combining traditional palletization techniques with Automated Mobile Robots (AMRs) that adapt to changing load patterns and optimize space utilization. These systems enable flexible stacking and real-time adjustments, significantly reducing labor costs and increasing throughput compared to static palletizing methods.

AMR-Supported Pallet Movement

Automated Mobile Robot (AMR) supported pallet movement enhances warehouse efficiency by enabling flexible, autonomous transportation of pallets without fixed infrastructure, reducing manual labor and minimizing errors. This technology integrates seamlessly with existing palletization processes, optimizing space utilization and accelerating order fulfillment through real-time navigation and dynamic path planning.

Intelligent Load Unitization

Intelligent load unitization enhances palletization by optimizing load stability, space utilization, and handling efficiency through advanced software algorithms and sensor integration. Automated Mobile Robot (AMR) handling streamlines warehouse operations by dynamically transporting intelligently palletized loads, reducing labor costs and increasing throughput.

Robotic Depalletization

Robotic depalletization in warehousing significantly enhances efficiency by automating the process of unloading products from pallets using automated mobile robots (AMRs), reducing manual labor and minimizing errors. Compared to traditional palletization, AMRs offer precise handling, adaptability to various load types, and seamless integration with warehouse management systems for optimized inventory flow.

Mixed-SKU Pallet Assembly

Mixed-SKU pallet assembly benefits from palletization by offering structured stacking and easy SKU identification, enhancing inventory accuracy and space utilization in warehouses. Automated Mobile Robot (AMR) handling accelerates the process with dynamic routing and real-time adjustments, reducing labor costs and increasing throughput for diverse product configurations.

AS/RS-Integrated AMR Handling

AS/RS-integrated Automated Mobile Robot (AMR) handling significantly enhances palletization efficiency by seamlessly combining automated storage and retrieval systems with mobile robots capable of dynamic material transport, reducing manual labor and increasing throughput. This integration optimizes warehouse space utilization and enables real-time inventory management by enabling precise pallet placement and retrieval within complex storage environments.

On-Demand Case Picking Robots

On-demand case picking robots enhance warehouse efficiency by combining palletization's organized storage benefits with the flexibility and precision of automated mobile robot handling. These robots optimize order fulfillment speed and accuracy, reducing labor costs while adapting dynamically to fluctuating inventory and demand.

Automated Pallet Wrapper Interface

Automated pallet wrapper interfaces seamlessly integrate with automated mobile robots (AMRs), enhancing palletization efficiency by ensuring consistent load stability and reducing manual labor. This technology optimizes warehouse throughput by enabling precise, repeatable wrapping cycles that adapt to varying pallet sizes and compositions, improving overall safety and operational speed.

Multi-Pallet AMR Coordination

Multi-pallet Automated Mobile Robot (AMR) coordination enhances warehouse efficiency by enabling simultaneous transport of several pallets, reducing bottlenecks and increasing throughput compared to traditional palletization methods. Advanced algorithms optimize path planning and load balancing, ensuring synchronized movement and minimizing collisions in complex multi-robot environments.

Digital Twin Warehouse Robotics

Digital Twin Warehouse Robotics enhances palletization by creating real-time virtual replicas of automated mobile robot (AMR) systems, optimizing inventory flow and task allocation with precision analytics. This integration reduces downtime and improves efficiency by simulating AMR movements and pallet stacking processes within a dynamic warehouse environment.

Palletization vs Automated Mobile Robot Handling Infographic

industrydif.com

industrydif.com