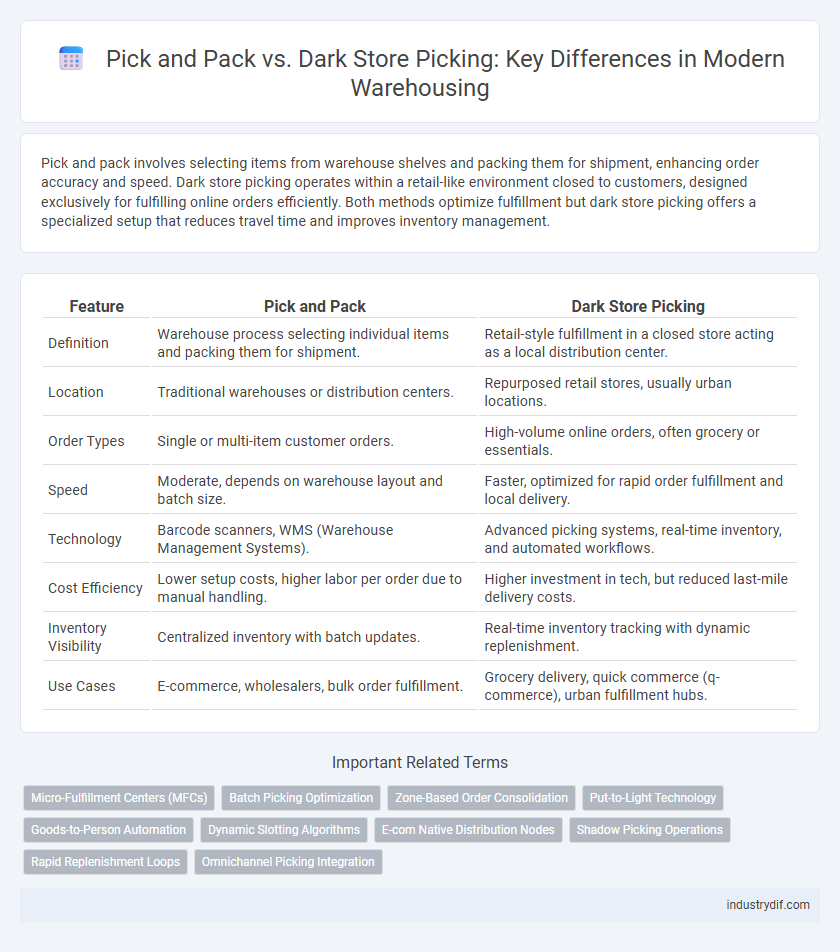

Pick and pack involves selecting items from warehouse shelves and packing them for shipment, enhancing order accuracy and speed. Dark store picking operates within a retail-like environment closed to customers, designed exclusively for fulfilling online orders efficiently. Both methods optimize fulfillment but dark store picking offers a specialized setup that reduces travel time and improves inventory management.

Table of Comparison

| Feature | Pick and Pack | Dark Store Picking |

|---|---|---|

| Definition | Warehouse process selecting individual items and packing them for shipment. | Retail-style fulfillment in a closed store acting as a local distribution center. |

| Location | Traditional warehouses or distribution centers. | Repurposed retail stores, usually urban locations. |

| Order Types | Single or multi-item customer orders. | High-volume online orders, often grocery or essentials. |

| Speed | Moderate, depends on warehouse layout and batch size. | Faster, optimized for rapid order fulfillment and local delivery. |

| Technology | Barcode scanners, WMS (Warehouse Management Systems). | Advanced picking systems, real-time inventory, and automated workflows. |

| Cost Efficiency | Lower setup costs, higher labor per order due to manual handling. | Higher investment in tech, but reduced last-mile delivery costs. |

| Inventory Visibility | Centralized inventory with batch updates. | Real-time inventory tracking with dynamic replenishment. |

| Use Cases | E-commerce, wholesalers, bulk order fulfillment. | Grocery delivery, quick commerce (q-commerce), urban fulfillment hubs. |

Introduction to Pick and Pack and Dark Store Picking

Pick and Pack is a warehousing process where individual items are selected from inventory and packaged for shipment, commonly used in e-commerce fulfillment centers. Dark Store Picking involves operating a retail-like warehouse closed to the public, optimized specifically for rapid order picking and dispatch. Both methods enhance order accuracy and speed but differ in layout and operational focus, with Pick and Pack supporting diverse item types and Dark Store Picking emphasizing streamlined, supermarket-style item retrieval.

Definition of Pick and Pack Fulfillment

Pick and pack fulfillment is a warehousing process where products are individually selected from inventory (picked) and then packaged together for shipping. This method emphasizes accuracy and efficiency in assembling customer orders for timely delivery. It contrasts with dark store picking, which involves dedicated locations designed solely for rapid online order fulfillment.

What is Dark Store Picking?

Dark Store Picking refers to a warehouse fulfillment strategy where products are stored and picked exclusively for online orders without customer-facing retail operations. This method accelerates order processing by optimizing layouts and workflows specifically for e-commerce demands, reducing picking errors and increasing efficiency. Dark stores function as dedicated distribution centers designed to handle high volumes of precise order fulfillment rapidly.

Key Differences Between Pick and Pack and Dark Store Picking

Pick and Pack operations involve selecting individual items from warehouse inventory and packaging them for shipment, typically servicing online orders with a focus on accuracy and speed. Dark Store Picking centers around fulfilling customer orders within a retail environment converted into a warehouse, optimizing for high SKU density and rapid order turnaround. Key differences include location use--dedicated warehouses versus retail-adapted stores--and process orientation, where Pick and Pack emphasizes individual item precision while Dark Store Picking prioritizes bulk picking efficiency.

Efficiency and Speed Comparison

Pick and Pack operations typically involve manual item selection and packaging within a traditional warehouse layout, which can slow order fulfillment due to travel time and item retrieval complexity. Dark Store Picking leverages specialized store-like setups optimized for rapid picking, significantly reducing walking distances and enabling faster processing of online orders. This streamlined environment enhances efficiency and speed, often resulting in higher throughput and quicker delivery times compared to conventional Pick and Pack methods.

Technology Utilization in Both Models

Pick and pack warehouses leverage barcode scanning, RFID, and warehouse management systems (WMS) to streamline order accuracy and inventory tracking. Dark store picking integrates advanced automation technologies such as robotic picking systems, AI-driven route optimization, and real-time data analytics to enhance speed and efficiency. Both models rely on IoT devices and cloud-based platforms to improve operational visibility and decision-making.

Cost Implications: Pick and Pack vs. Dark Store Picking

Pick and pack operations typically incur higher labor and overhead costs due to manual item retrieval and packaging in traditional warehouse settings. Dark store picking reduces expenses by streamlining order fulfillment in dedicated retail spaces optimized for rapid picking, minimizing handling time and labor intensity. Cost efficiencies in dark store models also arise from better inventory management and reduced need for large storage facilities.

Scalability for Growing E-Commerce Operations

Pick and pack warehouse systems offer scalable solutions by enabling efficient order fulfillment through batch processing and optimized picker routes, supporting surges in e-commerce demand. Dark store picking enhances scalability by operating as a dedicated fulfillment center with streamlined layouts, reducing picking times and increasing throughput during peak sales periods. Both methods leverage automation and real-time inventory tracking to adapt quickly to expanding product assortments and higher order volumes, essential for growing online retailers.

Challenges and Limitations of Each Method

Pick and pack operations often face challenges such as increased labor costs, slower order fulfillment during peak times, and errors in item selection due to human factor inefficiencies. Dark store picking encounters limitations including higher upfront setup expenses, reliance on technology integration, and difficulty adapting to fluctuating order volumes without flexible workforce management. Both methods require balancing speed, accuracy, and operational costs to optimize warehouse efficiency and customer satisfaction.

Choosing the Right Fulfillment Strategy for Your Business

Selecting the optimal fulfillment strategy hinges on understanding the distinct advantages of pick and pack versus dark store picking methodologies. Pick and pack excels in versatility and accuracy for e-commerce orders with diverse SKUs, while dark store picking enhances speed and efficiency by operating dedicated fulfillment centers optimized for high-volume retail distribution. Businesses should evaluate order volume, SKU variety, and delivery speed requirements to align their warehousing operations with customer expectations and operational cost-efficiency.

Related Important Terms

Micro-Fulfillment Centers (MFCs)

Pick and Pack involves selecting individual items from warehouse shelves to fulfill customer orders, whereas Dark Store Picking operates within Micro-Fulfillment Centers (MFCs) designed for rapid, automated order processing with minimal human intervention. MFCs leverage advanced robotics and real-time inventory management to enhance efficiency, reduce fulfillment times, and optimize space utilization compared to traditional Pick and Pack warehouses.

Batch Picking Optimization

Batch picking optimization significantly enhances warehouse efficiency by consolidating multiple orders into single pick routes, reducing travel time and labor costs compared to traditional pick and pack methods. Dark store picking leverages this optimization by utilizing dedicated fulfillment spaces that streamline batch processing, improve inventory accuracy, and accelerate order turnaround.

Zone-Based Order Consolidation

Zone-based order consolidation streamlines warehousing by assigning specific product categories to designated zones, enhancing efficiency in both pick and pack and dark store picking models. This method reduces travel time and errors by consolidating items within zones before final order assembly, significantly improving order accuracy and processing speed.

Put-to-Light Technology

Put-to-Light technology streamlines Pick and Pack operations by increasing accuracy and speed through real-time guided placement, reducing errors and labor costs. In Dark Store Picking, Put-to-Light enhances order fulfillment efficiency by enabling seamless sorting directly at picking zones, optimizing inventory flow without customer-facing distractions.

Goods-to-Person Automation

Goods-to-person automation in pick and pack warehouses enhances efficiency by delivering items directly to workers, significantly reducing travel time and order processing speed. Dark store picking leverages this automation for rapid fulfillment, enabling retailers to operate fulfillment centers designed solely for e-commerce with minimized human movement and maximized throughput.

Dynamic Slotting Algorithms

Dynamic slotting algorithms enhance pick and pack operations by optimizing item placement based on real-time demand patterns, reducing travel time and increasing order accuracy. In dark store picking, these algorithms adapt slotting configurations dynamically to streamline high-volume, time-sensitive order fulfillment, improving overall warehouse efficiency.

E-com Native Distribution Nodes

Pick and Pack warehouses optimize e-commerce native distribution by directly selecting and packaging items individual to each order, enhancing accuracy and speed for customer fulfillment. Dark store picking leverages retail-like inventory setups dedicated exclusively to online orders, improving efficiency through streamlined product accessibility and minimal in-store distractions.

Shadow Picking Operations

Shadow picking operations in warehousing streamline fulfillment by enabling pickers to collect items invisibly within retail environments, improving order accuracy and reducing lead times compared to traditional pick and pack methods. Dark store picking leverages dedicated, closed-off retail spaces designed exclusively for online order processing, optimizing inventory accessibility and enhancing the efficiency of shadow picking workflows.

Rapid Replenishment Loops

Pick and Pack operations streamline order fulfillment by selecting items from inventory and packaging them for shipment, whereas Dark Store Picking leverages dedicated fulfillment centers optimized for rapid, high-volume order processing. Rapid Replenishment Loops enhance both methods by continuously restocking picking zones in real-time, minimizing stockouts and maximizing efficiency in fast-paced e-commerce environments.

Omnichannel Picking Integration

Omnichannel picking integration streamlines both pick and pack and dark store picking by enabling real-time inventory updates and consolidated order management across multiple sales channels, enhancing operational efficiency and accuracy. Implementing advanced warehouse management systems (WMS) ensures seamless coordination between traditional store fulfillment and dark store operations, driving faster order processing and improved customer satisfaction.

Pick and Pack vs Dark Store Picking Infographic

industrydif.com

industrydif.com