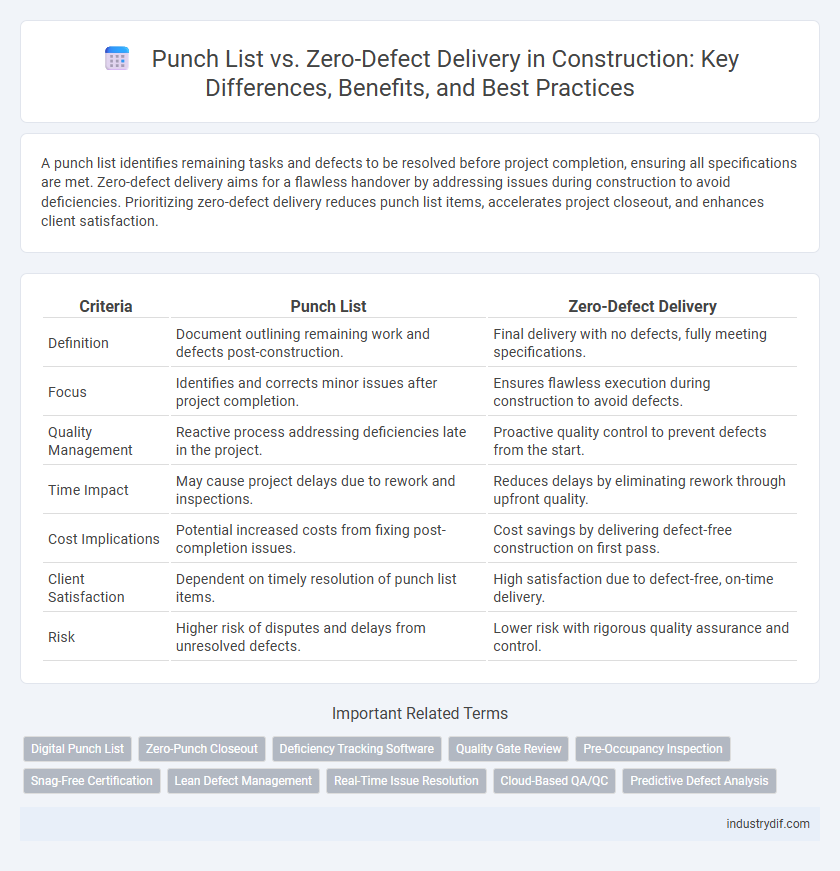

A punch list identifies remaining tasks and defects to be resolved before project completion, ensuring all specifications are met. Zero-defect delivery aims for a flawless handover by addressing issues during construction to avoid deficiencies. Prioritizing zero-defect delivery reduces punch list items, accelerates project closeout, and enhances client satisfaction.

Table of Comparison

| Criteria | Punch List | Zero-Defect Delivery |

|---|---|---|

| Definition | Document outlining remaining work and defects post-construction. | Final delivery with no defects, fully meeting specifications. |

| Focus | Identifies and corrects minor issues after project completion. | Ensures flawless execution during construction to avoid defects. |

| Quality Management | Reactive process addressing deficiencies late in the project. | Proactive quality control to prevent defects from the start. |

| Time Impact | May cause project delays due to rework and inspections. | Reduces delays by eliminating rework through upfront quality. |

| Cost Implications | Potential increased costs from fixing post-completion issues. | Cost savings by delivering defect-free construction on first pass. |

| Client Satisfaction | Dependent on timely resolution of punch list items. | High satisfaction due to defect-free, on-time delivery. |

| Risk | Higher risk of disputes and delays from unresolved defects. | Lower risk with rigorous quality assurance and control. |

Understanding Punch Lists in Construction Projects

Punch lists in construction projects serve as detailed checklists used during final inspections to identify incomplete or non-compliant work before project handover. These lists document specific tasks, quality issues, or defects requiring correction to ensure the project meets contractual standards. Proper management of punch lists is essential to achieving zero-defect delivery by addressing all deficiencies promptly and guaranteeing client satisfaction.

Defining Zero-Defect Delivery in the Industry

Zero-Defect Delivery in construction refers to the completion of a project with no defects or deficiencies, ensuring all work meets specified quality standards before handover. This approach eliminates rework, reduces costs, and enhances client satisfaction by delivering fully compliant and operational facilities. Unlike traditional punch lists that identify and correct defects post-completion, zero-defect delivery emphasizes preventive quality control and thorough inspections throughout the construction process.

Key Differences Between Punch List and Zero-Defect Delivery

Punch List involves identifying and documenting minor defects or incomplete work at the end of a construction project, requiring resolution before final acceptance. Zero-Defect Delivery emphasizes completing the project with no defects from the outset, aiming for flawless execution and reducing rework costs. The key difference lies in Punch List addressing corrections post-construction, while Zero-Defect Delivery prioritizes prevention and quality control throughout the project lifecycle.

Common Causes of Punch List Items

Common causes of punch list items in construction include incomplete work, poor quality finishes, and non-compliance with project specifications. Errors in measurements, overlooked safety installations, and inadequate coordination between trades often lead to discrepancies identified during final inspections. Addressing these issues early reduces delays and supports the goal of zero-defect delivery by ensuring all contractual requirements meet the highest standards.

Benefits of Pursuing Zero-Defect Delivery

Pursuing zero-defect delivery in construction significantly reduces rework costs and accelerates project completion by ensuring quality standards are met from the outset. This approach enhances client satisfaction by delivering fully compliant structures without the need for extensive punch list corrections. Implementing zero-defect principles also improves workforce accountability and streamlines inspection processes, boosting overall operational efficiency.

Industry Challenges in Achieving Zero-Defect Delivery

Achieving zero-defect delivery in construction is challenged by complex project scopes, varying subcontractor quality standards, and inconsistent inspection protocols. Industry constraints such as tight schedules and budget limits often force acceptance of minor defects, leading to reliance on punch lists for post-completion corrections. Advanced technologies and integrated quality management systems are essential to overcome these barriers and minimize defects at the delivery stage.

Effective Strategies for Punch List Management

Effective punch list management relies on detailed documentation, timely communication, and proactive defect tracking to ensure all completion tasks are addressed before project handover. Implementing digital punch list software streamlines issue identification, assignment, and resolution, reducing delays and enhancing accountability. Emphasizing thorough inspections and real-time updates supports zero-defect delivery by minimizing outstanding defects and improving overall construction quality.

Quality Control Measures for Zero-Defect Goals

Punch list management targets identifying and resolving construction defects before project handover, serving as a reactive quality control measure. Zero-defect delivery emphasizes proactive quality control strategies, including continuous inspections, real-time monitoring, and stringent compliance with design specifications to prevent defects altogether. Implementing advanced quality assurance protocols and integrating digital tools enhances defect detection, ensuring construction projects meet zero-defect objectives and improve overall client satisfaction.

Impact on Project Timeline and Budget

Punch list completion often extends project timelines and increases costs due to additional labor and materials needed for corrections. In contrast, zero-defect delivery minimizes delays and budget overruns by ensuring all project elements meet quality standards initially. Effective quality control and thorough inspections reduce the frequency of punch list items, accelerating project closeout and optimizing overall budget efficiency.

Future Trends in Construction Quality Assurance

Future trends in construction quality assurance emphasize transitioning from traditional punch list methods to zero-defect delivery models, leveraging advanced technologies like AI-driven inspections and real-time data analytics to minimize errors before project completion. Integration of IoT sensors and BIM systems enables continuous quality monitoring, reducing reliance on manual defect identification and accelerating project timelines. Embracing zero-defect delivery enhances client satisfaction and cost-efficiency by preventing rework and ensuring higher construction standards from the outset.

Related Important Terms

Digital Punch List

Digital Punch List software streamlines the identification, tracking, and resolution of construction defects, enhancing collaboration and transparency among project teams. Zero-Defect Delivery aims to eliminate rework by ensuring all punch list items are digitally documented and addressed before project closeout, optimizing quality control and client satisfaction.

Zero-Punch Closeout

Zero-Punch Closeout ensures all construction defects are resolved before project handover, eliminating the need for a traditional punch list and accelerating the transition to occupancy. This proactive approach reduces delays, improves client satisfaction, and enhances cost efficiency by delivering a truly zero-defect facility at closeout.

Deficiency Tracking Software

Deficiency tracking software streamlines punch list management by enabling real-time identification, categorization, and resolution of construction defects, accelerating project closeout and ensuring adherence to quality standards. Zero-defect delivery benefits from integrated digital platforms that monitor and document every issue, reducing rework costs and enhancing client satisfaction through systematic defect elimination.

Quality Gate Review

A Punch List identifies outstanding tasks or defects after construction completion, serving as a corrective measure before final handover. Zero-Defect Delivery demands a Quality Gate Review during each project phase to ensure all criteria meet stringent standards, preventing defects and minimizing costly rework.

Pre-Occupancy Inspection

Pre-Occupancy Inspection plays a crucial role in transitioning from a traditional Punch List approach to a Zero-Defect Delivery model by identifying and resolving defects before project completion. This proactive inspection strategy ensures all construction elements meet quality standards, minimizing rework and accelerating client handover.

Snag-Free Certification

Punch List documents capture outstanding construction tasks typically addressed post-completion, whereas Zero-Defect Delivery ensures all elements meet quality standards before handover, minimizing rework and delays. Snag-Free Certification validates a project's compliance with zero defects, enhancing stakeholder confidence and streamlining the final approval process.

Lean Defect Management

Lean Defect Management in construction emphasizes minimizing rework by integrating Punch List activities early and continuously throughout the project, ensuring that issues are resolved promptly before final delivery. Zero-Defect Delivery aims for flawless project completion by fostering proactive quality control, real-time defect tracking, and collaborative problem-solving to eliminate defects rather than just documenting them at the end.

Real-Time Issue Resolution

Punch list processes often delay project completion by identifying defects only after substantial work is finished, whereas zero-defect delivery emphasizes real-time issue resolution through continuous monitoring and immediate corrective actions. Implementing digital tools for real-time tracking accelerates defect detection, reduces rework costs, and enhances overall construction quality management.

Cloud-Based QA/QC

Cloud-based QA/QC platforms streamline punch list management by enabling real-time tracking and automated defect reporting, ensuring faster resolution and enhanced project transparency. Zero-defect delivery is achieved through continuous quality monitoring and data-driven insights provided by these digital tools, reducing rework and improving overall construction quality.

Predictive Defect Analysis

Predictive defect analysis enhances zero-defect delivery by utilizing data-driven algorithms to identify potential construction issues before project completion, reducing reliance on traditional punch list processes. Implementing predictive models lowers rework costs and accelerates project timelines by proactively addressing defects during construction phases.

Punch List vs Zero-Defect Delivery Infographic

industrydif.com

industrydif.com