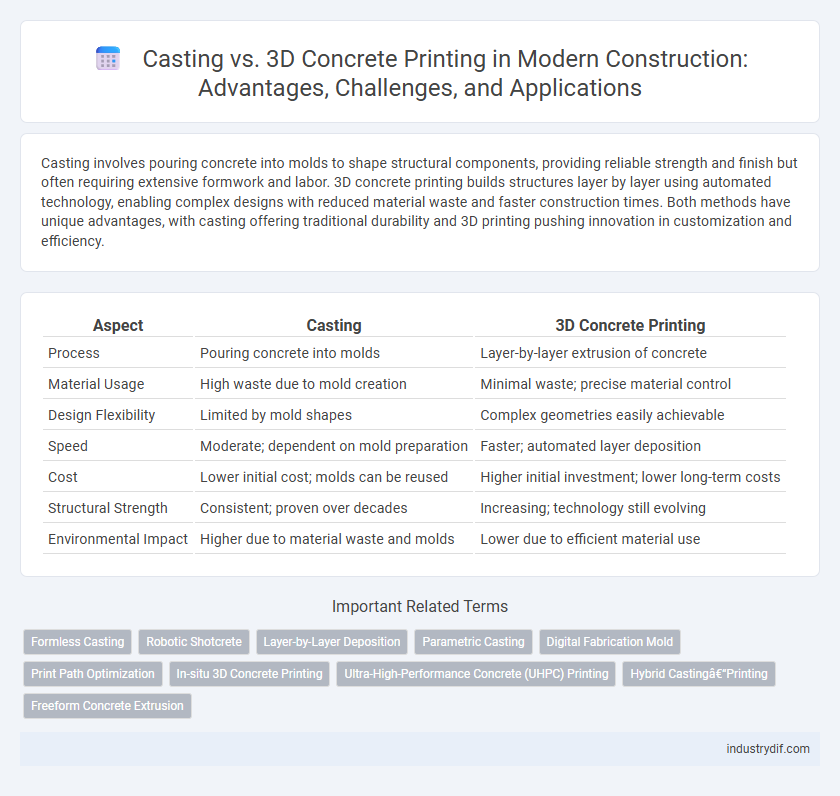

Casting involves pouring concrete into molds to shape structural components, providing reliable strength and finish but often requiring extensive formwork and labor. 3D concrete printing builds structures layer by layer using automated technology, enabling complex designs with reduced material waste and faster construction times. Both methods have unique advantages, with casting offering traditional durability and 3D printing pushing innovation in customization and efficiency.

Table of Comparison

| Aspect | Casting | 3D Concrete Printing |

|---|---|---|

| Process | Pouring concrete into molds | Layer-by-layer extrusion of concrete |

| Material Usage | High waste due to mold creation | Minimal waste; precise material control |

| Design Flexibility | Limited by mold shapes | Complex geometries easily achievable |

| Speed | Moderate; dependent on mold preparation | Faster; automated layer deposition |

| Cost | Lower initial cost; molds can be reused | Higher initial investment; lower long-term costs |

| Structural Strength | Consistent; proven over decades | Increasing; technology still evolving |

| Environmental Impact | Higher due to material waste and molds | Lower due to efficient material use |

Introduction to Casting and 3D Concrete Printing

Casting in construction involves pouring concrete into molds to create structural components with predefined shapes and sizes, ensuring uniformity and strength through controlled curing processes. 3D concrete printing uses automated additive manufacturing technology to layer concrete material precisely, allowing for complex geometries, reduced material waste, and faster production times. Both methods offer unique advantages, with casting excelling in traditional projects requiring mass production and 3D printing offering innovation in customization and rapid prototyping.

Historical Overview of Concrete Construction Methods

Casting has been a foundational concrete construction method for centuries, relying on molds to shape concrete into structural elements with high durability and versatility. In contrast, 3D concrete printing represents a revolutionary advancement, enabling precise layer-by-layer fabrication without traditional formwork, significantly reducing material waste and labor costs. The historical progression from manual casting techniques to automated 3D printing illustrates the industry's shift towards innovative and sustainable construction technologies.

Key Principles of Traditional Casting

Traditional casting in construction relies on creating molds to shape concrete, utilizing formwork materials such as wood, steel, or plastic to hold the mixture until it hardens. The process involves carefully mixing concrete components--cement, aggregates, water, and additives--to achieve desired strength and durability before pouring into the mold. Key principles include precise mold preparation, controlled curing conditions to prevent cracks, and ensuring structural integrity through reinforcement placement within the cast.

Fundamentals of 3D Concrete Printing Technology

3D concrete printing technology utilizes layer-by-layer extrusion of cementitious mixtures, enabling precise geometric complexity and reduced material waste compared to traditional casting methods. The fundamental process involves automated nozzle control governed by digital design files, enhancing speed and customization in construction projects. This technology also improves structural integrity through continuous material deposition, minimizing weak points associated with casting joints.

Material Requirements: Casting vs. 3D Printing

Casting requires materials with specific fluidity and setting times to ensure proper mold filling and structural integrity, typically involving traditional concrete mixes with additives for workability. 3D concrete printing demands specially formulated, high-performance mortars or concrete with precise rheological properties to enable extrusion, layer adhesion, and rapid setting without formwork. Material optimization plays a crucial role in both processes, influencing durability, strength, and environmental sustainability in advanced construction projects.

Speed and Efficiency Comparison

Casting methods in construction typically require extensive formwork setup and curing time, leading to longer project durations. In contrast, 3D concrete printing significantly reduces construction time by automating layer deposition, enabling rapid, on-site production with minimal labor. The efficiency of 3D printing also minimizes material waste and accelerates complex design implementation, offering a faster and more cost-effective alternative to traditional casting.

Design Flexibility and Architectural Possibilities

Casting methods offer limited design flexibility due to reliance on fixed molds, constraining complex geometries and intricate detailing. 3D concrete printing enables architects to realize highly customized, organic shapes with unprecedented precision, allowing for innovative structural elements and optimized material usage. This technology expands architectural possibilities by facilitating rapid prototyping and on-site fabrication without traditional formwork constraints.

Environmental Impact and Sustainability

Casting in construction often involves significant material waste and energy consumption due to formwork fabrication and repetitive processes. 3D concrete printing reduces waste by precisely depositing material layer-by-layer, optimizing resource use and minimizing carbon emissions associated with concrete production. This technology enhances sustainability by enabling intricate designs that use less concrete without compromising structural integrity, contributing to lower environmental impact overall.

Cost Analysis: Initial and Long-Term

Casting in construction typically involves higher initial labor and material costs due to formwork and skilled workforce requirements, while 3D concrete printing reduces these expenses through automation and minimal formwork. Long-term expenses favor 3D concrete printing because of reduced waste, faster project completion, and lower maintenance costs associated with precise layering and material efficiency. Cost analysis reveals 3D concrete printing as a more economical solution for large-scale projects and custom designs, despite potentially higher equipment investment in the initial phase.

Future Trends in Concrete Construction

Casting remains a dominant method in concrete construction due to its cost-effectiveness and scalability, but 3D concrete printing is revolutionizing the industry by enabling complex geometries and reducing material waste. Advances in robotics, AI-driven design algorithms, and sustainable material formulations are accelerating the adoption of 3D printing technologies, promising faster construction times and enhanced structural precision. Emerging trends indicate a hybrid approach, integrating traditional casting with additive manufacturing techniques to optimize strength, customization, and environmental impact in future projects.

Related Important Terms

Formless Casting

Formless casting eliminates the need for traditional molds by using adaptable materials that conform directly to desired shapes, enhancing customization and reducing waste in construction projects. Compared to 3D concrete printing, formless casting offers greater flexibility for complex geometries without layer lines, enabling seamless structural elements and faster onsite adaptation.

Robotic Shotcrete

Robotic shotcrete in 3D concrete printing enhances precision and reduces material waste compared to traditional casting methods by enabling layer-by-layer deposition controlled by advanced robotics. This technology improves structural integrity and accelerates construction timelines while minimizing labor costs and environmental impact.

Layer-by-Layer Deposition

Casting relies on pouring concrete into molds where it sets uniformly, while 3D concrete printing employs layer-by-layer deposition to build complex structures with precision and reduced material waste. This additive manufacturing process allows for intricate architectural designs and faster construction timelines compared to traditional casting methods.

Parametric Casting

Parametric casting leverages advanced digital design tools to create precise and complex formworks, enabling tailored concrete structures with reduced material waste compared to traditional casting methods. Unlike 3D concrete printing, which builds layer-by-layer additive forms, parametric casting optimizes molds for mass production while maintaining high customization and structural performance in construction projects.

Digital Fabrication Mold

Digital fabrication molds in casting offer precise control over complex geometries through traditional formwork, while 3D concrete printing eliminates molds completely by directly depositing layers of concrete, enabling faster construction and reduced material waste. Advanced software integration in 3D printing enhances customization and scalability, contrasting with casting's dependency on physical molds that limit design flexibility and increase production time.

Print Path Optimization

Print path optimization in 3D concrete printing significantly enhances build speed and material efficiency by minimizing travel distance and layer overlap, unlike traditional casting which relies on formwork and manual labor adjustments. Advanced algorithms analyze geometric complexity to create precise, continuous paths that reduce structural defects and waste, positioning 3D printing as a superior method for complex architectural elements.

In-situ 3D Concrete Printing

In-situ 3D concrete printing revolutionizes construction by depositing concrete layer-by-layer directly on-site, enabling complex geometries and reducing material waste compared to traditional casting methods. This technique enhances project efficiency and sustainability by minimizing formwork requirements and allowing rapid, precise structural fabrication tailored to specific architectural designs.

Ultra-High-Performance Concrete (UHPC) Printing

Ultra-High-Performance Concrete (UHPC) printing leverages 3D concrete printing technology to enable rapid, precise fabrication of complex geometries with superior mechanical properties and durability, surpassing traditional casting methods in material efficiency and structural performance. This advanced additive manufacturing process reduces formwork requirements and minimizes waste, making UHPC printing a sustainable innovation in modern construction.

Hybrid Casting–Printing

Hybrid casting-printing combines traditional concrete casting with advanced 3D printing technology to enhance structural precision and reduce material waste in construction projects. This integration enables complex geometries and faster build times while maintaining the strength and durability of conventional cast concrete.

Freeform Concrete Extrusion

Freeform concrete extrusion in 3D printing enables complex geometries and reduced material waste compared to traditional casting, which relies on molds and often limits design flexibility. This additive manufacturing process accelerates construction timelines and enhances structural customization, making it a transformative technology in modern concrete applications.

Casting vs 3D Concrete Printing Infographic

industrydif.com

industrydif.com