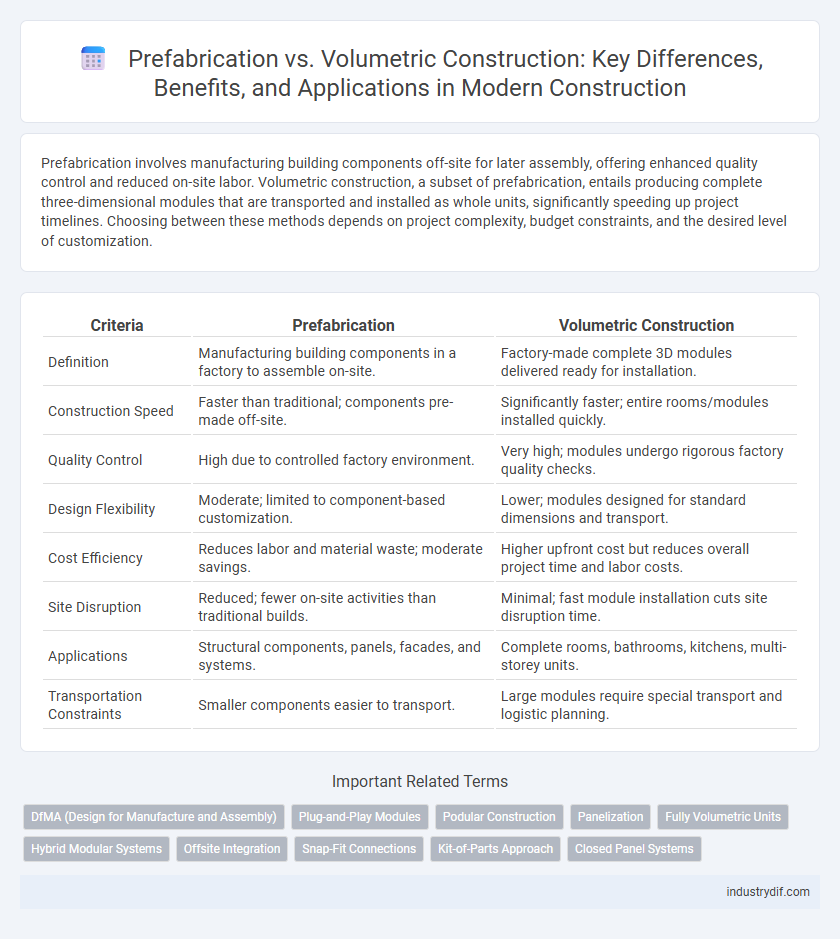

Prefabrication involves manufacturing building components off-site for later assembly, offering enhanced quality control and reduced on-site labor. Volumetric construction, a subset of prefabrication, entails producing complete three-dimensional modules that are transported and installed as whole units, significantly speeding up project timelines. Choosing between these methods depends on project complexity, budget constraints, and the desired level of customization.

Table of Comparison

| Criteria | Prefabrication | Volumetric Construction |

|---|---|---|

| Definition | Manufacturing building components in a factory to assemble on-site. | Factory-made complete 3D modules delivered ready for installation. |

| Construction Speed | Faster than traditional; components pre-made off-site. | Significantly faster; entire rooms/modules installed quickly. |

| Quality Control | High due to controlled factory environment. | Very high; modules undergo rigorous factory quality checks. |

| Design Flexibility | Moderate; limited to component-based customization. | Lower; modules designed for standard dimensions and transport. |

| Cost Efficiency | Reduces labor and material waste; moderate savings. | Higher upfront cost but reduces overall project time and labor costs. |

| Site Disruption | Reduced; fewer on-site activities than traditional builds. | Minimal; fast module installation cuts site disruption time. |

| Applications | Structural components, panels, facades, and systems. | Complete rooms, bathrooms, kitchens, multi-storey units. |

| Transportation Constraints | Smaller components easier to transport. | Large modules require special transport and logistic planning. |

Understanding Prefabrication in Construction

Prefabrication in construction involves manufacturing building components off-site in a controlled factory environment, enabling higher precision, reduced waste, and faster on-site assembly. This method contrasts with volumetric construction, which assembles complete 3D modules off-site and then transports them for installation, offering benefits in speed and quality control. Understanding prefabrication emphasizes its role in improving project efficiency, cost-effectiveness, and sustainability by integrating standardized processes and minimizing on-site labor demands.

What is Volumetric Construction?

Volumetric construction involves manufacturing complete building modules off-site in controlled factory environments, integrating structural, mechanical, electrical, and finishing components. These three-dimensional units are transported to the construction site and assembled, reducing on-site labor and construction time. This method enhances quality control, minimizes waste, and improves project predictability compared to traditional prefabrication techniques.

Key Differences Between Prefabrication and Volumetric Construction

Prefabrication involves manufacturing individual building components off-site, which are then transported and assembled on-site, enhancing precision and reducing construction time. Volumetric construction, a subset of prefabrication, refers to the complete assembly of three-dimensional modules off-site, which are installed as whole units, streamlining labor and minimizing on-site disruptions. Key differences lie in the scale of off-site production and the level of integration, with volumetric construction offering more comprehensive, ready-to-install modules compared to the component-based approach of prefabrication.

Benefits of Prefabrication Methods

Prefabrication methods in construction significantly reduce onsite labor costs by assembling components in controlled factory environments, enhancing quality control and minimizing errors. These processes accelerate project timelines through parallel workflows, allowing site preparation and component fabrication to occur simultaneously. Improved material efficiency and waste reduction in prefabrication contribute to sustainable building practices and lower overall project expenses.

Advantages of Volumetric Construction

Volumetric construction offers significant advantages including reduced construction time by assembling pre-finished modules off-site, which leads to faster project completion and minimized on-site disruptions. It enhances quality control due to factory-controlled environments, ensuring higher precision and consistency compared to traditional prefabrication methods. Furthermore, volumetric construction improves sustainability by reducing waste and allowing efficient use of materials through standardized production processes.

Applications: Prefabrication vs Volumetric Construction

Prefabrication is widely applied in building components such as walls, floors, and roofs, allowing for efficient assembly on-site and enhancing quality control. Volumetric construction offers complete 3D modules like entire rooms or apartments, ideal for high-rise buildings and modular housing where speed and reduced labor costs are critical. Both methods optimize construction timelines, but volumetric construction excels in projects requiring rapid on-site installation and minimal disruption.

Cost Comparison: Prefabrication vs Volumetric Solutions

Prefabrication typically reduces labor costs by up to 30% through off-site assembly of components, while volumetric construction can further lower expenses by integrating full room units, minimizing on-site work and shortening project timelines by 30-50%. Material savings are achieved in volumetric methods due to precise factory conditions that reduce waste compared to traditional prefabrication. Evaluating initial investments, volumetric construction requires higher upfront capital but offers better cost efficiency over the project lifecycle due to reduced labor, logistics, and time overruns.

Sustainability and Environmental Impact

Prefabrication reduces on-site waste by manufacturing components in controlled factory settings, enhancing material efficiency and minimizing environmental disruption. Volumetric construction further optimizes sustainability by integrating fully assembled modules, cutting transportation emissions and accelerating project timelines. Both methods lower carbon footprints compared to traditional construction, promoting resource conservation and energy-efficient building lifecycle management.

Challenges and Limitations in Both Methods

Prefabrication faces challenges such as transportation logistics, site constraints, and limited customization options, while volumetric construction struggles with high initial costs, complex structural integration, and coordination among multiple trades. Both methods require precise planning and skilled labor to mitigate risks related to assembly errors and quality control. Limitations include reduced flexibility for late design changes and potential issues with scalability and adaptability to varied project types.

Future Trends in Industrialized Construction Techniques

Prefabrication and volumetric construction are evolving rapidly with advancements in automation, robotics, and digital design, driving efficiency and reducing onsite labor requirements. Integration of Building Information Modeling (BIM) and Internet of Things (IoT) sensors enhances precision and quality control, enabling smarter, data-driven decision-making in industrialized construction. The future trends emphasize sustainable materials, modular adaptability, and accelerated project timelines, positioning these techniques as pivotal solutions for addressing global housing demands and infrastructure challenges.

Related Important Terms

DfMA (Design for Manufacture and Assembly)

Prefabrication involves manufacturing building components off-site for on-site assembly, enhancing quality control and reducing construction time, while volumetric construction integrates entire three-dimensional modules including finishes and services, enabling faster installation and minimized on-site labor. Design for Manufacture and Assembly (DfMA) principles optimize both methods by streamlining design complexity, improving material efficiency, and facilitating easier transport and assembly to achieve cost savings and sustainability in construction projects.

Plug-and-Play Modules

Plug-and-play modules in prefabrication enable rapid assembly with standardized components manufactured off-site, reducing on-site labor and construction time. Volumetric construction involves fully finished three-dimensional units delivered ready to install, offering higher quality control and minimizing weather-related delays.

Podular Construction

Podular construction, a subset of volumetric construction, involves assembling modules or pods off-site under controlled factory conditions, enhancing quality control and reducing on-site labor. This method accelerates project timelines by enabling simultaneous site preparation and module fabrication, resulting in efficient, scalable building solutions compared to traditional prefabrication techniques.

Panelization

Panelization in construction involves fabricating large wall panels offsite, offering flexibility and faster assembly compared to volumetric construction, which delivers fully assembled volumetric modules. Utilizing advanced panelization techniques enhances precision, reduces on-site labor, and optimizes material usage, making it a cost-effective method in prefabricated building projects.

Fully Volumetric Units

Fully volumetric units in construction refer to the off-site manufacturing of complete 3D modules that include finishes, fixtures, and fittings, enabling rapid on-site assembly and significantly reducing construction time. Compared to traditional prefabrication methods, fully volumetric construction enhances quality control, minimizes waste, and improves project efficiency by delivering ready-to-use building components.

Hybrid Modular Systems

Hybrid modular systems combine the precision of prefabrication with the scalability of volumetric construction, enabling faster project completion and reduced on-site labor costs. These systems integrate prefabricated components with volumetric modules to optimize structural integrity, material usage, and design flexibility in modern construction projects.

Offsite Integration

Offsite integration in prefabrication involves assembling individual components or modules in controlled environments before transporting them to the construction site, enhancing precision and reducing onsite labor. Volumetric construction takes offsite integration further by delivering fully finished, three-dimensional units ready for immediate installation, significantly accelerating project timelines and improving quality control.

Snap-Fit Connections

Snap-fit connections in prefabrication offer quick assembly and disassembly without the need for additional fasteners, enhancing modularity and reducing labor costs on construction sites. Volumetric construction benefits from these connections by enabling precise, factory-controlled quality and rapid on-site installation, streamlining project timelines and improving structural integrity.

Kit-of-Parts Approach

The Kit-of-Parts approach in prefabrication utilizes standardized, pre-manufactured components to streamline assembly and improve quality control, contrasting with volumetric construction which emphasizes complete three-dimensional modules. Prefabrication's Kit-of-Parts method enables greater design flexibility, faster on-site installation, and reduced material waste compared to the fixed dimensions and heavier logistics associated with volumetric construction.

Closed Panel Systems

Closed panel systems in prefabrication involve factory-built wall panels complete with insulation and sheathing, offering precise quality control and faster on-site assembly. Volumetric construction, by contrast, delivers fully finished three-dimensional modules, significantly reducing construction time but requiring greater transport logistics and coordination.

Prefabrication vs Volumetric Construction Infographic

industrydif.com

industrydif.com