Safety harnesses provide essential fall protection by physically securing workers at heights, while wearable sensor technology enhances workplace safety through real-time monitoring of vital signs and hazard detection. Combining harnesses with wearable sensors improves overall risk management by delivering immediate alerts and documenting safety compliance. This integration optimizes worker protection and reduces accidents on construction sites.

Table of Comparison

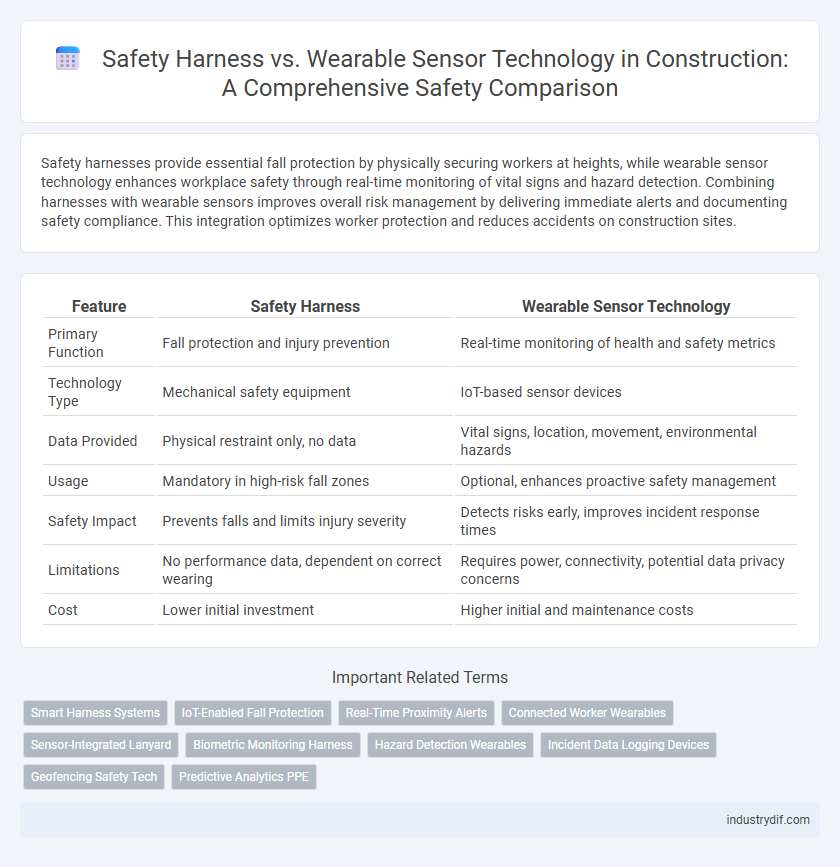

| Feature | Safety Harness | Wearable Sensor Technology |

|---|---|---|

| Primary Function | Fall protection and injury prevention | Real-time monitoring of health and safety metrics |

| Technology Type | Mechanical safety equipment | IoT-based sensor devices |

| Data Provided | Physical restraint only, no data | Vital signs, location, movement, environmental hazards |

| Usage | Mandatory in high-risk fall zones | Optional, enhances proactive safety management |

| Safety Impact | Prevents falls and limits injury severity | Detects risks early, improves incident response times |

| Limitations | No performance data, dependent on correct wearing | Requires power, connectivity, potential data privacy concerns |

| Cost | Lower initial investment | Higher initial and maintenance costs |

Introduction to Construction Safety Technologies

Construction safety technologies have evolved from traditional safety harnesses to include advanced wearable sensor technology, enhancing worker protection on-site. Safety harnesses provide essential fall protection by physically securing workers at height, while wearable sensors offer real-time monitoring of environmental hazards, worker vitals, and movement patterns. Integrating these technologies improves overall safety management, reducing accident risks and enabling timely intervention during emergencies.

Evolution of Safety Harnesses in Construction

Safety harnesses in construction have evolved from basic restraint systems to advanced, ergonomic designs featuring impact indicators and quick-connect buckles for enhanced user safety and comfort. Modern harnesses integrate wearable sensor technology that monitors worker health metrics and environmental hazards in real-time, significantly reducing accident risks. This fusion of traditional safety gear with digital innovation marks a transformative shift in workforce protection standards on construction sites.

Wearable Sensor Technology: An Overview

Wearable sensor technology in construction offers real-time monitoring of workers' vital signs and environmental conditions, significantly enhancing on-site safety. These devices track parameters such as heart rate, body temperature, and exposure to hazardous gases, enabling early detection of potential health risks. Integration with smart systems allows immediate alerts and data analytics, reducing accidents and improving emergency response times.

Key Features of Traditional Safety Harnesses

Traditional safety harnesses provide essential fall protection in construction environments through adjustable straps and secure buckles designed to distribute force evenly during a fall. Constructed from durable materials like nylon or polyester webbing, they offer high tensile strength and resistance to wear and tear. These harnesses often include attachment points such as D-rings for lanyards, enabling reliable connection to anchor systems and compliance with OSHA safety standards.

Advancements in Wearable Sensor Solutions

Wearable sensor technology in construction has advanced significantly, providing real-time monitoring of worker vitals and environmental conditions to enhance safety beyond traditional safety harnesses. These sensors detect hazards such as toxic gas exposure, excessive heat, and falls, enabling immediate alerts and preventative actions. Integration with IoT platforms allows for comprehensive data analysis, improving risk management and reducing workplace accidents on construction sites.

Comparing Safety Standards: Harness vs Sensor

Safety harnesses comply with strict occupational safety standards such as OSHA and ANSI, providing physical fall restraint and arrest capabilities essential for high-risk construction tasks. Wearable sensor technology enhances safety by continuously monitoring environmental hazards and worker biometrics, offering real-time alerts that help prevent accidents before they occur. Comparing these standards, harnesses focus on direct physical protection validated by rigorous certification, while sensors deliver proactive risk management through data-driven insights and compliance with emerging digital safety regulations.

Real-Time Monitoring Capabilities

Safety harnesses provide essential fall protection by physically securing workers at height but lack real-time monitoring capabilities to detect hazardous conditions instantly. Wearable sensor technology enhances construction safety through continuous, real-time monitoring of worker movements, environmental hazards, and vital signs, enabling immediate alerts and proactive response to potential dangers. Integrating wearable sensors with safety harness systems significantly improves on-site safety management by combining physical protection with advanced hazard detection and data analytics.

Impact on Worker Productivity and Comfort

Safety harnesses provide essential fall protection but can sometimes restrict movement, leading to discomfort and reduced worker productivity during prolonged use. Wearable sensor technology enhances safety by continuously monitoring worker vitals and environmental conditions without impeding mobility, thereby improving comfort and enabling more efficient work performance. Integrating sensor data with harness systems offers a balanced approach, optimizing both safety compliance and operational productivity on construction sites.

Cost Analysis: Upfront and Long-Term Investments

Safety harnesses require a lower upfront investment, typically ranging from $50 to $150 per unit, offering durable protection with minimal maintenance costs. Wearable sensor technology demands higher initial expenses, often exceeding $500 per device, but enables continuous monitoring that can reduce long-term operational risks and insurance premiums. Over time, the integration of wearable sensors may yield cost savings through enhanced safety data analytics and proactive hazard prevention, offsetting the initial capital outlay.

Future Trends in Construction Site Safety

Future trends in construction site safety emphasize the integration of safety harnesses with wearable sensor technology to enhance real-time monitoring and fall prevention. Wearable sensors provide data on worker location, vital signs, and movement patterns, enabling predictive analytics to prevent accidents before they occur. The combination of traditional safety harnesses and advanced IoT-enabled wearables represents a significant shift towards proactive and data-driven construction safety management.

Related Important Terms

Smart Harness Systems

Smart harness systems integrate wearable sensor technology to enhance worker safety by continuously monitoring vital signs, movement, and environmental hazards in real-time. These systems provide instant alerts for fall detection, fatigue, and unsafe postures, significantly reducing workplace accidents and improving compliance with construction safety regulations.

IoT-Enabled Fall Protection

IoT-enabled fall protection systems combine traditional safety harnesses with wearable sensor technology to monitor worker movement and detect falls in real time, enhancing site safety through immediate alerts and data analytics. These smart devices integrate GPS, accelerometers, and Bluetooth connectivity to provide proactive risk management and improve rescue response times in construction environments.

Real-Time Proximity Alerts

Safety harnesses provide fall protection by physically restraining workers, while wearable sensor technology enhances construction site safety through real-time proximity alerts that detect hazardous distances between personnel and equipment. Integrating wearable sensors with existing safety protocols enables immediate hazard awareness, reducing collision risks and improving overall worker protection on-site.

Connected Worker Wearables

Safety harnesses provide essential fall protection in construction, while wearable sensor technology enhances worker safety by continuously monitoring vital signs, movement, and environmental hazards. Connected worker wearables integrate both physical safety gear and real-time data analytics to improve hazard detection, incident prevention, and emergency response on construction sites.

Sensor-Integrated Lanyard

Sensor-integrated lanyards combine traditional safety harness functions with real-time wearable sensor technology, enabling continuous monitoring of worker posture, movement, and fall risks on construction sites. This integration enhances fall prevention measures by providing data-driven alerts and improving overall site safety compliance.

Biometric Monitoring Harness

Biometric monitoring harnesses integrate wearable sensor technology to continuously track vital signs such as heart rate, body temperature, and fatigue levels, enhancing worker safety on construction sites by providing real-time health data. These advanced safety harnesses enable early detection of physical stress and hazardous conditions, reducing the risk of accidents and improving emergency response times.

Hazard Detection Wearables

Safety harnesses provide essential fall protection by physically securing workers at heights, while wearable sensor technology enhances hazard detection through real-time monitoring of environmental risks such as toxic gas levels, vibrations, and worker biometrics. Integrating hazard detection wearables with safety harnesses significantly improves construction site safety by enabling proactive incident prevention and faster emergency response.

Incident Data Logging Devices

Safety harnesses primarily provide fall protection by physically securing workers at heights, while wearable sensor technology enhances incident data logging by continuously monitoring and recording real-time movements, impacts, and environmental conditions. Integrating wearable sensors with safety harnesses enables precise incident data capture, facilitating proactive risk management and improved compliance with construction safety regulations.

Geofencing Safety Tech

Safety harnesses provide essential physical fall protection on construction sites, while wearable sensor technology enhances worker safety by utilizing geofencing to monitor real-time location and alert personnel entering hazardous zones. Geofencing safety tech integrates GPS and IoT sensors to create virtual boundaries that trigger automated warnings, reducing accident risks and improving site compliance.

Predictive Analytics PPE

Safety harnesses provide critical fall protection in construction, while wearable sensor technology enhances predictive analytics by continuously monitoring workers' biometrics and environmental conditions to preemptively identify hazards. Integrating wearable sensors with PPE generates real-time data that improves risk assessments, reduces accident rates, and supports proactive safety interventions on job sites.

Safety Harness vs Wearable Sensor Technology Infographic

industrydif.com

industrydif.com