Blast hole drilling uses explosives to create fractures in rock, enabling efficient material extraction in mining operations. Solar thermal fragmentation employs concentrated solar energy to induce thermal stresses, breaking rock without explosives and reducing environmental impact. Choosing between these methods depends on factors like project scale, environmental regulations, and operational costs.

Table of Comparison

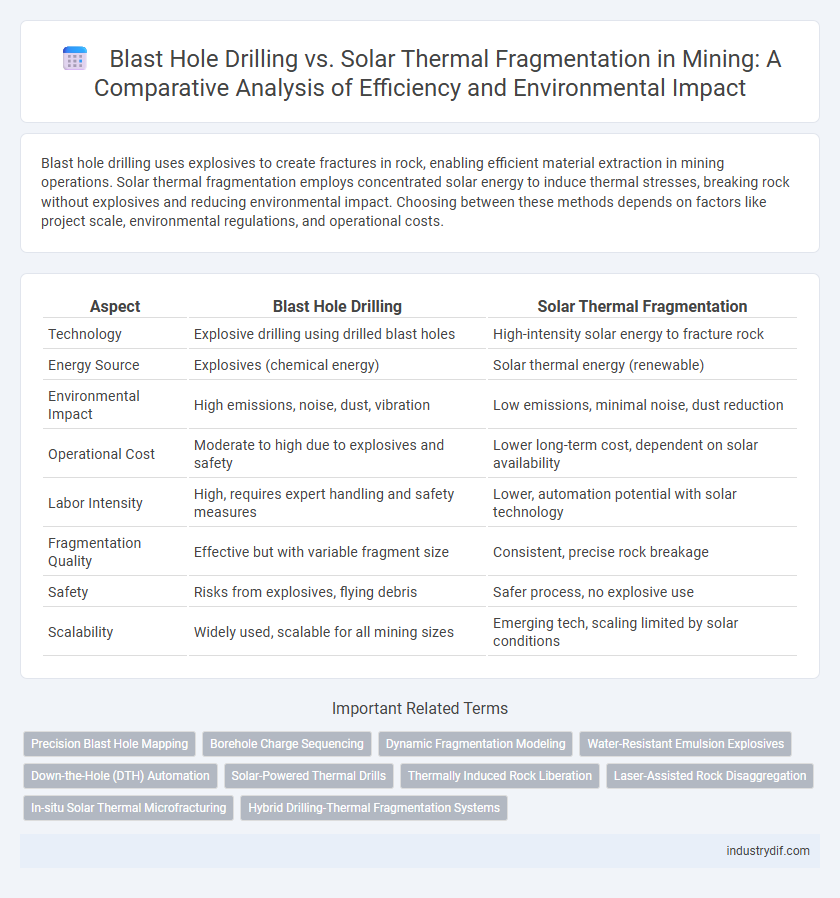

| Aspect | Blast Hole Drilling | Solar Thermal Fragmentation |

|---|---|---|

| Technology | Explosive drilling using drilled blast holes | High-intensity solar energy to fracture rock |

| Energy Source | Explosives (chemical energy) | Solar thermal energy (renewable) |

| Environmental Impact | High emissions, noise, dust, vibration | Low emissions, minimal noise, dust reduction |

| Operational Cost | Moderate to high due to explosives and safety | Lower long-term cost, dependent on solar availability |

| Labor Intensity | High, requires expert handling and safety measures | Lower, automation potential with solar technology |

| Fragmentation Quality | Effective but with variable fragment size | Consistent, precise rock breakage |

| Safety | Risks from explosives, flying debris | Safer process, no explosive use |

| Scalability | Widely used, scalable for all mining sizes | Emerging tech, scaling limited by solar conditions |

Overview of Blast Hole Drilling

Blast hole drilling is a conventional mining technique involving the use of rotary or percussion drills to create holes for loading explosives in rock fragmentation. It offers precise control over hole depth and diameter, enabling efficient fragmentation and optimized blasting patterns for diverse geological conditions. This method remains widely adopted due to its proven reliability and adaptability in open-pit and underground mining operations.

Introduction to Solar Thermal Fragmentation

Solar thermal fragmentation employs concentrated solar energy to induce thermal stresses in rock, causing it to fracture without conventional explosives or mechanical drilling. This innovative method offers a sustainable alternative to blast hole drilling by reducing vibrations, noise, and environmental impact. Enhanced precision in rock breakage improves safety and efficiency in mining operations.

Operational Principles: How Each Method Works

Blast hole drilling involves creating a series of holes in rock formations where explosives are inserted and detonated to fragment the rock for easier extraction. Solar thermal fragmentation uses concentrated solar energy to heat and crack rock surfaces without explosives, utilizing mirrors or lenses to focus sunlight on targeted areas. The blast hole technique relies on controlled explosions for mechanical breaking, while solar thermal fragmentation depends on thermal stress induced by intense heat to achieve rock disintegration.

Efficiency Comparison: Speed and Throughput

Blast hole drilling achieves high throughput with speeds up to several meters per minute, enabling rapid fragmentation in large-scale mining operations. Solar thermal fragmentation, while slower at current development stages, offers precise control and reduced environmental impact but generally processes material at a lower rate compared to traditional drilling. Efficiency comparisons highlight blast hole drilling's superior speed and volume handling, though solar thermal methods present promising advancements for energy-efficient mining.

Energy Consumption and Sustainability

Blast hole drilling in mining consumes high amounts of energy primarily from diesel-powered machinery, leading to significant carbon emissions and environmental impact. Solar thermal fragmentation, using concentrated solar energy to fracture rock, offers a sustainable alternative by reducing fossil fuel reliance and decreasing overall energy consumption. This innovative technology enhances energy efficiency while supporting carbon emission reduction goals in mining operations.

Cost Analysis: Capital and Operating Expenses

Blast hole drilling requires significant capital investment in heavy machinery, drilling consumables, and skilled labor, with operating expenses driven by fuel, maintenance, and drill bit replacements. Solar thermal fragmentation involves high initial costs for solar concentrators, thermal energy storage, and specialized equipment, but offers lower ongoing expenses due to reduced fuel consumption and minimal mechanical wear. Overall, solar thermal fragmentation presents potential long-term cost savings through decreased operating costs despite higher upfront capital expenses compared to conventional blast hole drilling.

Safety and Environmental Impacts

Blast hole drilling in mining poses risks of dust exposure, vibrations, and noise pollution, impacting worker safety and nearby communities, while solar thermal fragmentation offers a safer alternative by minimizing harmful emissions and reducing physical hazards. Solar thermal technology significantly lowers environmental footprints through decreased energy consumption and elimination of explosives, promoting sustainable mining practices. Both methods require careful evaluation, but solar thermal fragmentation presents enhanced safety and environmental benefits.

Suitability for Different Rock Types

Blast hole drilling is highly effective for hard and dense rock formations, providing precise hole placement and controlled fragmentation suitable for conventional mining operations. Solar thermal fragmentation excels in brittle or thermally responsive rock types, using concentrated solar energy to induce fractures without mechanical contact, reducing wear on equipment. The choice between methods depends on rock hardness, porosity, and mineral composition, impacting operational efficiency and fragmentation quality.

Equipment Requirements and Maintenance

Blast hole drilling equipment typically includes drill rigs, drill bits, and water pumps, requiring regular maintenance such as bit replacement and lubrication to ensure operational efficiency. Solar thermal fragmentation relies on concentrated solar power systems and thermal panels, demanding upkeep of optical components and thermal control units to maintain consistent energy output. Maintenance for blast hole drilling is more mechanical-intensive, whereas solar thermal fragmentation requires specialized care for its advanced thermal equipment and energy systems.

Future Trends in Mining Fragmentation Technologies

Blast hole drilling remains a dominant method in mining fragmentation due to its efficiency and scalability for hard rock excavation. Emerging solar thermal fragmentation technologies promise reduced environmental impact by utilizing concentrated solar energy to induce thermal stress and rock breakage without explosives. Future trends indicate a hybrid approach integrating traditional blast hole drilling with solar thermal methods to enhance sustainability and operational efficiency in mining.

Related Important Terms

Precision Blast Hole Mapping

Precision blast hole mapping enhances the accuracy of blast hole drilling by providing detailed spatial data and geological variations that optimize drill placement and fragmentation outcomes. In comparison, solar thermal fragmentation relies on controlled energy application without the need for extensive mapping, making precision blast hole mapping a critical factor in maximizing drill efficiency and minimizing operational risks in conventional mining.

Borehole Charge Sequencing

Borehole charge sequencing in blast hole drilling involves precise timing and order of explosive detonations to optimize rock fragmentation and reduce ground vibrations. In contrast, solar thermal fragmentation uses controlled thermal stresses without explosives, eliminating the need for charge sequencing while offering a more environmentally friendly and energy-efficient alternative.

Dynamic Fragmentation Modeling

Dynamic fragmentation modeling in blast hole drilling employs advanced simulations to optimize explosive energy distribution, enhancing rock breakage efficiency and minimizing environmental impact. In contrast, solar thermal fragmentation uses concentrated solar energy to induce thermal stress fractures, with modeling focusing on heat transfer dynamics and fracture propagation to improve precision and reduce operational costs.

Water-Resistant Emulsion Explosives

Water-resistant emulsion explosives enhance blast hole drilling efficiency by providing superior stability and sensitivity in wet conditions, ensuring consistent detonation in challenging mine environments. In contrast, solar thermal fragmentation offers a non-explosive alternative for rock breaking, but lacks the proven reliability of water-resistant emulsion explosives in submerged or water-affected boreholes.

Down-the-Hole (DTH) Automation

Down-the-Hole (DTH) automation in blast hole drilling enhances precision and efficiency by integrating advanced sensor technologies and real-time monitoring systems, reducing operational downtime and optimizing energy consumption. Solar thermal fragmentation offers a complementary green alternative by using concentrated solar energy to weaken rock structures pre-drilling, potentially reducing drill bit wear and maintenance costs while improving overall fragmentation quality.

Solar-Powered Thermal Drills

Solar-powered thermal drills use concentrated solar energy to generate high-temperature heat for rock fragmentation, offering a sustainable alternative to traditional blast hole drilling that relies on explosives and fossil fuels. This method reduces environmental impact by minimizing emissions and noise while enhancing safety in mining operations through precise, controlled thermal fracturing.

Thermally Induced Rock Liberation

Thermally induced rock liberation in mining leverages solar thermal fragmentation to create microfractures within the rock matrix, enhancing breakage efficiency compared to traditional blast hole drilling that relies on explosive energy to fracture rock mechanically. Solar thermal methods reduce environmental impact by minimizing dust, vibration, and noise while enabling precise control over fracture patterns, optimizing material recovery and processing costs.

Laser-Assisted Rock Disaggregation

Laser-assisted rock disaggregation in blast hole drilling enhances precision by using high-powered lasers to create controlled fractures, reducing explosive use and minimizing environmental impact. Solar thermal fragmentation offers an energy-efficient alternative by concentrating solar energy to heat and weaken rock structures, but laser technology provides superior control and adaptability for complex ore bodies in mining operations.

In-situ Solar Thermal Microfracturing

In-situ solar thermal microfracturing offers a non-explosive alternative to traditional blast hole drilling by using concentrated solar energy to create precise fractures within rock formations, significantly reducing environmental impact and operational costs. This method enhances ore recovery efficiency by minimizing ground vibrations and airblast effects, making it especially suitable for sensitive mining environments and complex geological conditions.

Hybrid Drilling-Thermal Fragmentation Systems

Hybrid drilling-thermal fragmentation systems integrate blast hole drilling with solar thermal fragmentation to enhance efficiency and reduce energy consumption in mining operations. Combining precise mechanical drilling and concentrated solar energy enables deeper, cleaner rock breakage while minimizing explosives use and environmental impact.

Blast Hole Drilling vs Solar Thermal Fragmentation Infographic

industrydif.com

industrydif.com