Surface mining offers direct access to mineral deposits, enabling efficient extraction of large volumes of ore with minimal underground hazards. Autonomous mining leverages advanced robotics and AI to enhance safety, reduce labor costs, and optimize operational efficiency by automating tasks such as drilling, hauling, and blasting. Integrating autonomous technologies in surface mining significantly improves productivity while minimizing environmental impact and human exposure to hazardous conditions.

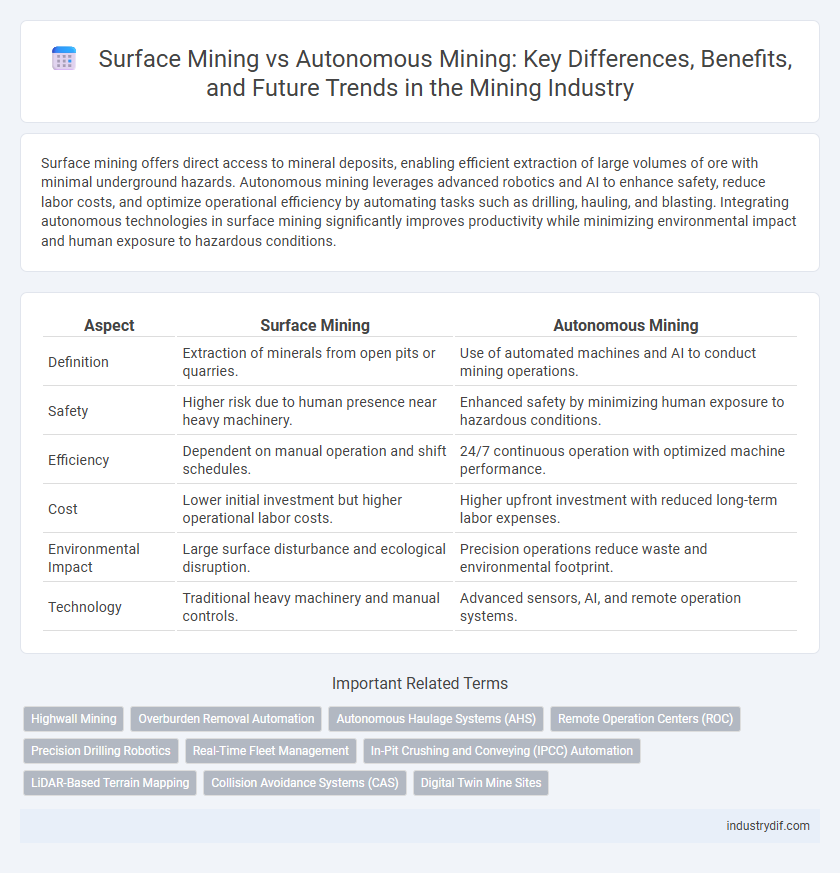

Table of Comparison

| Aspect | Surface Mining | Autonomous Mining |

|---|---|---|

| Definition | Extraction of minerals from open pits or quarries. | Use of automated machines and AI to conduct mining operations. |

| Safety | Higher risk due to human presence near heavy machinery. | Enhanced safety by minimizing human exposure to hazardous conditions. |

| Efficiency | Dependent on manual operation and shift schedules. | 24/7 continuous operation with optimized machine performance. |

| Cost | Lower initial investment but higher operational labor costs. | Higher upfront investment with reduced long-term labor expenses. |

| Environmental Impact | Large surface disturbance and ecological disruption. | Precision operations reduce waste and environmental footprint. |

| Technology | Traditional heavy machinery and manual controls. | Advanced sensors, AI, and remote operation systems. |

Introduction to Surface Mining and Autonomous Mining

Surface mining involves the removal of soil and rock layers to access mineral deposits near the earth's surface, utilizing equipment such as draglines, shovels, and trucks for excavation and transportation. Autonomous mining integrates advanced technologies like AI, robotics, and remote sensing to automate drilling, hauling, and monitoring processes, improving safety and operational efficiency. Combining surface mining techniques with autonomous systems reduces human intervention, lowers operational costs, and enhances real-time data analysis for optimized resource extraction.

Key Differences Between Surface Mining and Autonomous Mining

Surface mining involves traditional methods where heavy machinery is manually operated on open-pit or strip mines to extract minerals, emphasizing large-scale earth removal. Autonomous mining utilizes advanced robotics and AI-driven vehicles to perform excavation, hauling, and processing tasks with minimal human intervention, increasing safety and operational efficiency. Key differences include labor requirements, with autonomous mining reducing the need for on-site workers, and precision, as autonomous systems enable real-time data analysis and optimized resource extraction.

Technological Advances in Mining Operations

Surface mining has evolved significantly with the integration of advanced machinery and GPS technology, enabling precise extraction and reduced environmental impact. Autonomous mining employs AI-driven equipment and real-time data analytics to enhance safety, operational efficiency, and resource utilization. Technological advances such as drones, IoT sensors, and machine learning algorithms continuously optimize mining operations, transforming traditional surface mining into smart, autonomous systems.

Safety Implications: Manual vs Autonomous Mining

Surface mining operations expose workers to hazards such as ground instability, heavy machinery accidents, and dust inhalation, making manual mining inherently risky. Autonomous mining employs remote-controlled or AI-driven machines, significantly reducing human presence in dangerous zones and thereby lowering injury rates and fatality risks. Implementation of autonomous technology enhances safety protocols by enabling real-time monitoring, predictive maintenance, and automated emergency response systems.

Productivity and Efficiency in Surface vs Autonomous Mining

Surface mining achieves productivity through large-scale earthmoving equipment and high operational capacity, but autonomous mining enhances efficiency by reducing human error and enabling continuous 24/7 operations. Autonomous systems leverage advanced sensors, AI, and remote monitoring to optimize resource extraction with minimal downtime, leading to higher overall throughput compared to traditional surface mining methods. Integration of automation technology in mining sites significantly lowers operational costs while increasing precision and safety in ore recovery processes.

Environmental Impact of Traditional and Automated Mining

Surface mining often leads to significant environmental degradation, including habitat destruction, soil erosion, and increased carbon emissions due to heavy machinery use. Autonomous mining reduces ecological footprints by optimizing equipment efficiency, lowering fuel consumption, and minimizing human error, which results in less environmental disruption. Advances in automated technologies promote sustainable mining practices by enabling precise resource extraction and improved reclamation efforts.

Workforce Transformation: Labor in Automated Mining

Surface mining traditionally relies on a large, on-site labor force for equipment operation, maintenance, and safety oversight, leading to significant human resource requirements and risk exposure. Autonomous mining integrates advanced robotics, AI, and remote operation systems that reduce the need for manual labor, shifting workforce roles toward technical oversight, data analysis, and system management. This transformation enhances operational efficiency, improves worker safety by minimizing exposure to hazardous environments, and demands a workforce skilled in automation technology and digital mining systems.

Cost Analysis: Surface Mining vs Autonomous Mining

Surface mining typically incurs higher operational costs due to extensive labor requirements, fuel consumption, and equipment maintenance. Autonomous mining reduces costs by leveraging automated machinery that enhances efficiency, minimizes human error, and decreases labor expenses. Long-term cost savings in autonomous mining also arise from improved safety, reduced downtime, and optimized resource extraction processes.

Implementation Challenges and Barriers

Surface mining faces implementation challenges such as high initial capital expenditure for equipment and environmental regulations that restrict land use and waste management practices. Autonomous mining encounters barriers including technological complexities in integrating AI systems with existing operations, cybersecurity risks, and the need for skilled personnel to manage and maintain automated machinery. Both methods demand significant investment in infrastructure and training, but autonomous mining offers long-term efficiency gains despite initial adoption hurdles.

Future Trends in Mining: Towards Full Autonomy

Future trends in mining emphasize a shift from traditional surface mining techniques towards fully autonomous systems that integrate AI-driven machinery with real-time data analytics. Autonomous mining improves operational efficiency, enhances worker safety, and reduces environmental impact by enabling remote monitoring and precise extraction processes. As innovations in robotics and IoT advance, the mining industry increasingly adopts smart, self-operating equipment to achieve sustainable and cost-effective resource extraction.

Related Important Terms

Highwall Mining

Highwall mining integrates the precision of autonomous systems with surface mining techniques to extract coal efficiently from exposed coal seams, reducing environmental impact compared to traditional surface mining. Autonomous highwall mining machines optimize the extraction process by minimizing human intervention and enhancing safety through remote operation and continuous monitoring.

Overburden Removal Automation

Surface mining increasingly integrates overburden removal automation to enhance operational efficiency, reduce labor costs, and improve safety by deploying autonomous machinery like automated excavators and haul trucks. Autonomous mining technology enables precise, real-time monitoring and control of overburden extraction processes, leading to optimized material displacement and minimized environmental impact compared to traditional surface mining methods.

Autonomous Haulage Systems (AHS)

Autonomous Haulage Systems (AHS) in surface mining enhance operational efficiency by utilizing GPS, sensors, and AI to navigate and haul materials without human intervention, significantly reducing labor costs and improving safety. AHS technology enables continuous, precise, and optimized truck movements, increasing productivity and minimizing fuel consumption compared to conventional surface mining methods with manually operated vehicles.

Remote Operation Centers (ROC)

Remote Operation Centers (ROC) revolutionize surface mining by enabling centralized control of autonomous mining equipment, enhancing safety and operational efficiency through real-time monitoring and data analytics. Autonomous mining systems integrated with ROC reduce human exposure to hazardous conditions while optimizing resource extraction and minimizing downtime.

Precision Drilling Robotics

Surface mining relies on traditional drilling techniques that often lack precision, whereas autonomous mining employs advanced precision drilling robotics to enhance accuracy and efficiency. Precision drilling robotics utilize real-time data analytics and automated controls to optimize blast patterns, reduce material waste, and minimize environmental impact.

Real-Time Fleet Management

Surface mining relies on manual operation and scheduled maintenance, limiting real-time responsiveness, whereas autonomous mining integrates advanced sensors and AI to enable dynamic Real-Time Fleet Management, optimizing equipment utilization and reducing operational costs. Real-time data analytics in autonomous fleets enhances decision-making by continuously monitoring machine health, location, and productivity, significantly improving safety and efficiency in surface mining operations.

In-Pit Crushing and Conveying (IPCC) Automation

In-pit crushing and conveying (IPCC) automation enhances surface mining efficiency by integrating autonomous systems that reduce reliance on traditional truck haulage, lowering operational costs and carbon emissions. Autonomous IPCC technologies enable continuous material handling with improved safety and precision, optimizing ore extraction processes and increasing overall mine productivity.

LiDAR-Based Terrain Mapping

Surface mining relies heavily on traditional LiDAR-based terrain mapping to create accurate digital elevation models, enabling efficient extraction planning and slope stability analysis. Autonomous mining integrates advanced LiDAR sensors with real-time data processing algorithms to generate precise, dynamic terrain maps that enhance vehicle navigation and operational safety.

Collision Avoidance Systems (CAS)

Surface mining integrates Collision Avoidance Systems (CAS) to enhance operator safety by detecting obstacles and preventing vehicle collisions, while autonomous mining leverages advanced CAS technologies combined with AI-driven sensors to enable vehicles to navigate complex environments independently, significantly reducing human error. The evolution from traditional CAS to fully autonomous systems improves operational efficiency, minimizes accidents, and facilitates continuous, uninterrupted mining activities.

Digital Twin Mine Sites

Surface mining integrated with autonomous mining technologies leverages Digital Twin Mine Sites to create real-time, data-driven simulations that optimize operational efficiency and safety. Digital twins enable comprehensive monitoring and predictive maintenance by mirroring physical mining processes, enhancing decision-making in large-scale surface mining environments.

Surface mining vs Autonomous mining Infographic

industrydif.com

industrydif.com