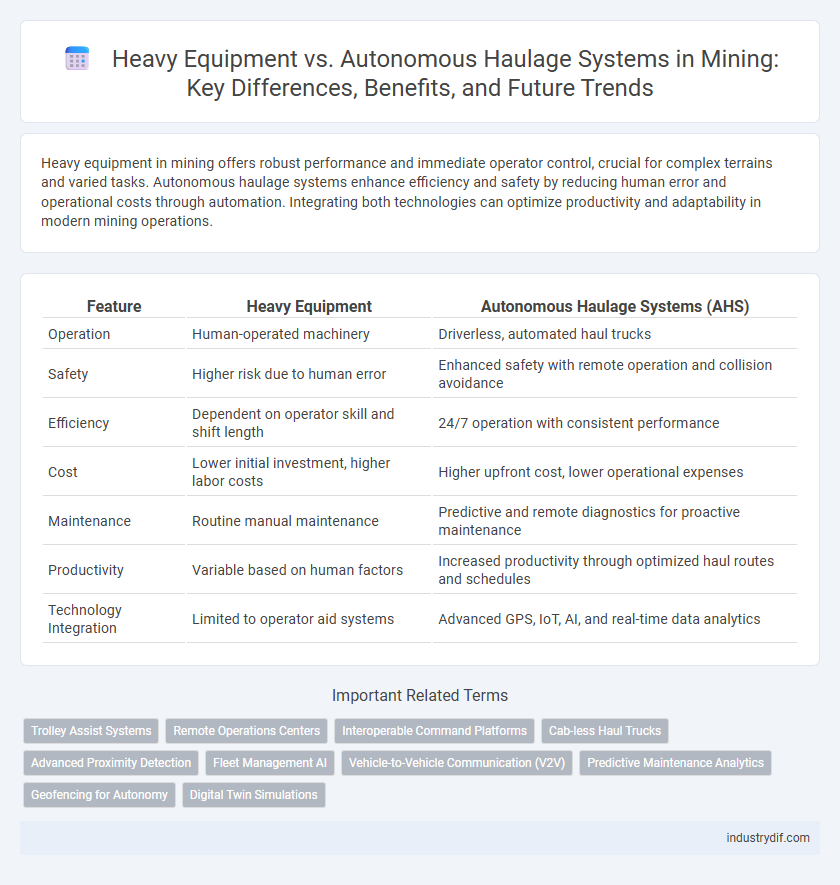

Heavy equipment in mining offers robust performance and immediate operator control, crucial for complex terrains and varied tasks. Autonomous haulage systems enhance efficiency and safety by reducing human error and operational costs through automation. Integrating both technologies can optimize productivity and adaptability in modern mining operations.

Table of Comparison

| Feature | Heavy Equipment | Autonomous Haulage Systems (AHS) |

|---|---|---|

| Operation | Human-operated machinery | Driverless, automated haul trucks |

| Safety | Higher risk due to human error | Enhanced safety with remote operation and collision avoidance |

| Efficiency | Dependent on operator skill and shift length | 24/7 operation with consistent performance |

| Cost | Lower initial investment, higher labor costs | Higher upfront cost, lower operational expenses |

| Maintenance | Routine manual maintenance | Predictive and remote diagnostics for proactive maintenance |

| Productivity | Variable based on human factors | Increased productivity through optimized haul routes and schedules |

| Technology Integration | Limited to operator aid systems | Advanced GPS, IoT, AI, and real-time data analytics |

Introduction to Heavy Equipment in Mining

Heavy equipment in mining includes large machines such as excavators, bulldozers, and haul trucks, essential for excavation, material handling, and earthmoving tasks. These machines offer reliability and flexibility in diverse mining environments, enabling efficient extraction and transport of minerals. Autonomous haulage systems are transforming traditional operations by integrating advanced sensors and AI to enhance productivity and safety in open-pit mines.

Evolution of Haulage Systems in the Mining Industry

The evolution of haulage systems in the mining industry has transitioned from traditional heavy equipment to advanced autonomous haulage systems (AHS), significantly improving operational efficiency and safety. Autonomous haulage systems leverage AI, GPS, and real-time data analytics to optimize route planning, reduce fuel consumption, and minimize human error. This shift has enabled mining operations to achieve higher productivity, lower operational costs, and enhanced environmental sustainability through precise, automated vehicle control.

Overview of Autonomous Haulage Systems (AHS)

Autonomous Haulage Systems (AHS) revolutionize mining operations by employing driverless trucks equipped with advanced sensors, GPS, and AI technologies to optimize haulage efficiency and safety. These systems enable continuous, precise vehicle control, reducing human error and operational costs while increasing productivity in surface mining environments. Integrating AHS with fleet management software enhances real-time data analytics, asset utilization, and overall site coordination.

Operational Efficiency: Traditional Equipment vs Autonomous Systems

Heavy equipment in mining relies heavily on human operators, which can introduce variability in operational efficiency and increase downtime due to fatigue or errors. Autonomous haulage systems utilize advanced sensors, AI, and GPS technology to optimize routes, reduce cycle times, and maintain consistent operational output around the clock. Studies show autonomous systems can improve productivity by up to 20% while significantly reducing fuel consumption and maintenance costs compared to traditional equipment.

Safety Improvements with Autonomous Haulage

Autonomous haulage systems (AHS) significantly enhance safety in mining operations by reducing human exposure to hazardous environments and minimizing risks associated with driver fatigue and human error. Advanced sensors and AI algorithms enable continuous monitoring and real-time decision-making, preventing collisions and equipment malfunctions. Data from autonomous fleets demonstrate a marked decrease in incident rates compared to traditional heavy equipment operated manually.

Cost Implications: Manual vs Autonomous Operations

Manual heavy equipment in mining requires significant labor costs, including wages, training, and safety measures, leading to higher operational expenses. Autonomous haulage systems reduce the need for human operators, lowering labor costs while enhancing productivity through continuous operation and optimized fuel consumption. Although initial capital expenditure for autonomous technology is substantial, the long-term cost savings from improved efficiency, reduced downtime, and minimized human error contribute to a more favorable total cost of ownership.

Environmental Impact of Heavy Equipment and AHS

Heavy equipment in mining operations generates significant greenhouse gas emissions due to diesel fuel consumption, contributing to air pollution and climate change. Autonomous haulage systems (AHS) reduce environmental impact by optimizing fuel efficiency, minimizing idling times, and enabling precise route planning, leading to lower carbon footprints. Studies indicate that AHS implementation can decrease diesel consumption by up to 15%, significantly mitigating the mining sector's overall environmental footprint.

Workforce Transformation: Skills and Roles

Heavy equipment operation in mining requires skilled operators trained in machinery control, maintenance, and safety protocols, emphasizing manual expertise. Autonomous haulage systems shift workforce roles towards technical oversight, data analysis, and system management, demanding advanced software and robotics skills. This transition drives workforce transformation by creating new job functions in automation supervision while reducing traditional operator positions.

Integration Challenges and Adoption Barriers

Integration challenges in mining arise as heavy equipment and autonomous haulage systems require compatible communication protocols, standardized data formats, and robust safety measures to operate collectively. Adoption barriers include high initial investment costs, workforce resistance due to skill gaps, and concerns over operational reliability and cybersecurity vulnerabilities. Overcoming these obstacles demands coordinated industry standards and targeted training programs to maximize efficiency gains and ensure seamless technology integration.

Future Trends in Mining Haulage Technologies

Future trends in mining haulage technologies emphasize the integration of autonomous haulage systems (AHS) that enhance operational efficiency, safety, and cost-effectiveness compared to traditional heavy equipment. Advances in artificial intelligence, machine learning, and IoT connectivity enable AHS to optimize routes, reduce fuel consumption, and minimize human error in large-scale mining operations. Continued innovation in sensor technology and real-time data analytics drives the transition from conventional heavy machinery to automated, remotely controlled haulage solutions that reshape the mining industry's productivity landscape.

Related Important Terms

Trolley Assist Systems

Trolley Assist Systems integrate electric-powered overhead lines with heavy mining trucks, reducing diesel fuel consumption and emissions while enhancing operational efficiency in haulage. These systems enable autonomous haulage vehicles to draw power from overhead cables on uphill segments, decreasing mechanical wear and extending equipment lifespan in large-scale mining operations.

Remote Operations Centers

Remote Operations Centers (ROCs) enhance mining efficiency by overseeing autonomous haulage systems (AHS) that reduce the reliance on traditional heavy equipment operators. These centers enable real-time monitoring and control of multiple autonomous trucks, optimizing fleet productivity and minimizing downtime in large-scale mining operations.

Interoperable Command Platforms

Interoperable command platforms enable seamless integration between heavy equipment and autonomous haulage systems, enhancing operational efficiency and real-time data exchange. These platforms allow diverse mining machinery to communicate, coordinate, and optimize payload transport while minimizing downtime and improving safety standards.

Cab-less Haul Trucks

Cab-less haul trucks in autonomous haulage systems significantly enhance mining efficiency by eliminating the need for onboard drivers, reducing labor costs and safety risks associated with manned heavy equipment. These vehicles use advanced sensors, GPS, and artificial intelligence to navigate complex mine sites autonomously, leading to increased productivity and lower operational downtime compared to traditional haul trucks.

Advanced Proximity Detection

Advanced proximity detection in autonomous haulage systems enhances safety by using LiDAR, radar, and cameras to detect obstacles and personnel in real-time, significantly reducing collision risks compared to traditional heavy equipment with limited sensor integration. These sophisticated systems enable continuous monitoring and immediate automated responses, improving operational efficiency and worker protection in mining environments.

Fleet Management AI

Fleet Management AI enhances operational efficiency by optimizing routes, maintenance schedules, and real-time vehicle diagnostics in both heavy equipment and autonomous haulage systems. Autonomous haulage systems leverage AI-driven fleet management to reduce human error, lower fuel consumption, and increase uptime compared to traditional heavy equipment operations.

Vehicle-to-Vehicle Communication (V2V)

Vehicle-to-Vehicle Communication (V2V) enhances Autonomous Haulage Systems (AHS) by enabling real-time data exchange between machines, increasing safety and operational efficiency in mining sites compared to traditional heavy equipment. This connectivity reduces collision risks, optimizes fleet coordination, and supports predictive maintenance, driving significant improvements in productivity and cost savings.

Predictive Maintenance Analytics

Heavy equipment in mining requires frequent manual inspections to identify potential faults, while autonomous haulage systems leverage predictive maintenance analytics through IoT sensors and machine learning algorithms, enabling real-time monitoring and early detection of component failures. Predictive maintenance analytics improves operational efficiency by reducing downtime, optimizing repair schedules, and extending the lifespan of autonomous vehicles compared to traditional heavy equipment.

Geofencing for Autonomy

Geofencing technology in autonomous haulage systems enhances mining operations by creating virtual boundaries that improve safety, route optimization, and real-time monitoring, significantly reducing human error compared to heavy equipment operated manually. This advanced geospatial control enables precise navigation and restricts autonomous vehicles to designated zones, boosting operational efficiency and lowering the risk of collisions or unauthorized access.

Digital Twin Simulations

Digital twin simulations in mining enable precise modeling of heavy equipment and autonomous haulage systems to optimize operational efficiency and reduce downtime. By integrating real-time data from autonomous haulage systems, digital twins facilitate predictive maintenance and enhance safety protocols compared to traditional heavy equipment.

Heavy equipment vs Autonomous haulage systems Infographic

industrydif.com

industrydif.com