Drilling and blasting involve creating fractures in rock through the use of explosives, facilitating the extraction of valuable minerals in large-scale mining operations. Borehole mining, on the other hand, utilizes high-pressure water jets to erode and retrieve ores through drilled boreholes, offering a more precise and environmentally friendly alternative. While drilling and blasting are effective for breaking hard rock, borehole mining minimizes surface disturbance and reduces the risks associated with explosive use.

Table of Comparison

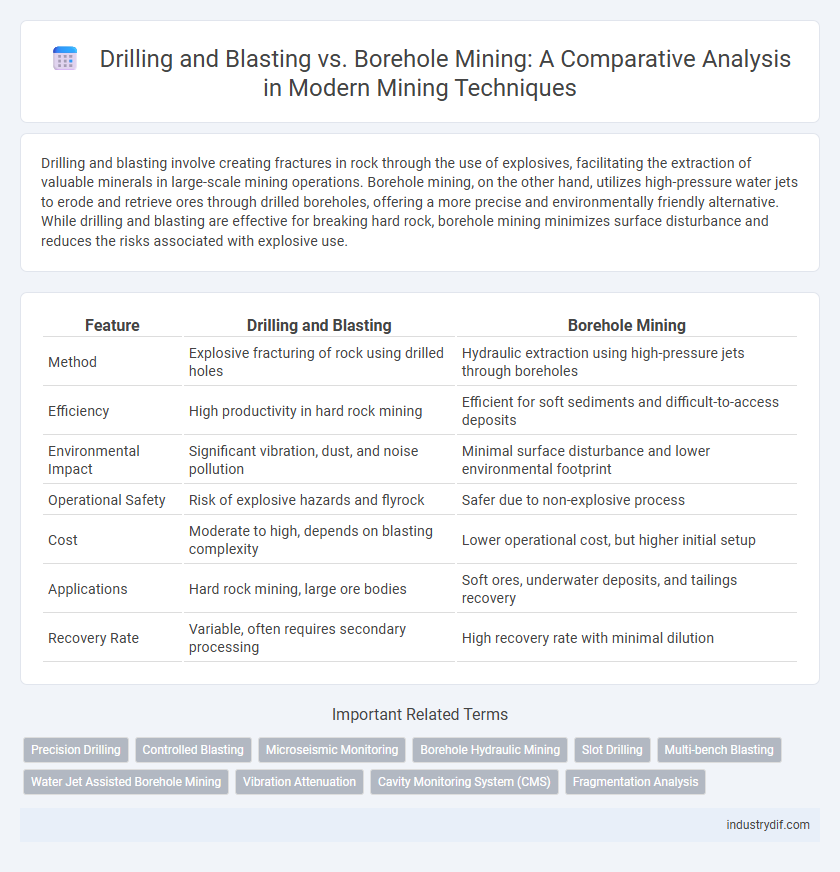

| Feature | Drilling and Blasting | Borehole Mining |

|---|---|---|

| Method | Explosive fracturing of rock using drilled holes | Hydraulic extraction using high-pressure jets through boreholes |

| Efficiency | High productivity in hard rock mining | Efficient for soft sediments and difficult-to-access deposits |

| Environmental Impact | Significant vibration, dust, and noise pollution | Minimal surface disturbance and lower environmental footprint |

| Operational Safety | Risk of explosive hazards and flyrock | Safer due to non-explosive process |

| Cost | Moderate to high, depends on blasting complexity | Lower operational cost, but higher initial setup |

| Applications | Hard rock mining, large ore bodies | Soft ores, underwater deposits, and tailings recovery |

| Recovery Rate | Variable, often requires secondary processing | High recovery rate with minimal dilution |

Overview of Drilling and Blasting in Mining

Drilling and blasting is a traditional mining technique involving the creation of boreholes drilled into rock before being filled with explosives to fragment the material for extraction. This method is widely used in surface and underground mining operations to break hard rock efficiently, enabling the removal of ore or coal. Compared to borehole mining, drilling and blasting offers greater control over fragmentation size and is more suitable for large-scale excavation projects with complex geology.

Introduction to Borehole Mining Techniques

Borehole mining techniques involve extracting minerals through narrow, vertical boreholes using high-pressure water jets to break and retrieve ore, minimizing surface disturbance compared to traditional drilling and blasting methods. Unlike conventional blasting, borehole mining offers precision and reduces environmental impact by eliminating explosive use and mitigating vibration and dust generation. This method is particularly effective in soft to medium-hard mineral deposits, enhancing safety and operational efficiency in modern mining projects.

Equipment Used in Drilling and Blasting

Drilling and blasting in mining primarily utilize rotary drills, jumbo drills, and pneumatic drills to create boreholes, followed by explosive charges for rock fragmentation. Equipment such as blast hole drills, detonators, and explosives like ANFO (ammonium nitrate fuel oil) are critical for efficient rock breakage and fragmentation. This contrasts with borehole mining, which employs hydraulic mining tools and slurry pumps, emphasizing mechanical excavation over explosive methods.

Technology Behind Borehole Mining

Borehole mining utilizes advanced mechanical and hydraulic technologies to extract minerals through slender boreholes, minimizing surface disturbance compared to traditional drilling and blasting methods. This technology employs high-pressure water jets and specialized tools to selectively dislodge ores, enhancing precision and reducing environmental impact. Integration of real-time monitoring and control systems in borehole mining optimizes resource recovery and improves operational safety.

Comparative Safety Considerations

Drilling and blasting in mining involve controlled explosions that pose risks such as flyrock, vibrations, and dust, requiring stringent safety protocols and exclusion zones. Borehole mining offers enhanced safety by using high-pressure jets to extract minerals through boreholes, minimizing ground vibrations and eliminating explosive hazards. The reduced risk of surface damage and improved control over extraction parameters make borehole mining a safer alternative in sensitive or densely populated mining areas.

Environmental Impact: Drilling and Blasting vs. Borehole Mining

Drilling and blasting generate significant noise, dust, and vibrations, leading to habitat disruption and air quality deterioration. Borehole mining minimizes surface disturbance and reduces airborne pollutants, preserving local ecosystems and water quality. The lower environmental footprint of borehole mining supports sustainable resource extraction compared to traditional drilling and blasting methods.

Cost Efficiency Analysis

Drilling and blasting typically incur higher operational costs due to extensive labor, explosives, and equipment wear, making it less cost-efficient for smaller or complex deposits. Borehole mining offers lower capital expenditure and reduced environmental impact, with superior cost efficiency in extracting minerals from deep or inaccessible ore bodies. Analyzing cost efficiency highlights borehole mining's advantage in minimizing downtime and material waste compared to traditional drilling and blasting methods.

Ore Recovery Rates and Selectivity

Drilling and blasting techniques typically achieve ore recovery rates ranging from 70% to 90%, with limited selectivity due to the indiscriminate fracturing of surrounding rock. Borehole mining offers higher selectivity, allowing targeted extraction of ore with minimal dilution and recovery rates often exceeding 90%. Enhanced ore recovery and precision in borehole mining reduce waste material and improve overall operational efficiency in mineral extraction.

Application Suitability for Different Mineral Deposits

Drilling and blasting is highly effective for hard rock mining, especially in large, consolidated ore bodies such as gold, copper, and iron deposits, where robust fragmentation is essential for extraction. Borehole mining suits unconsolidated, soft sediments or thin, shallow deposits like clay, sandstone, and some uranium ores, enabling selective and minimal-impact mineral recovery. Each method's application suitability depends on deposit geology, depth, and environmental considerations, optimizing operational efficiency and resource extraction.

Future Trends in Mining Extraction Methods

Drilling and blasting remain dominant in hard rock mining due to cost-efficiency and established technology, yet borehole mining gains traction for selective extraction with minimal surface disruption. Future trends emphasize automation, remote operation, and environmentally sustainable practices, with borehole mining expected to expand in deeper or inaccessible deposits. Integration of AI-driven analytics and real-time monitoring will enhance precision and safety across both extraction methods, optimizing resource recovery while reducing environmental impact.

Related Important Terms

Precision Drilling

Precision drilling in drilling and blasting offers targeted fragmentation and efficient rock breakage through controlled explosive placement, minimizing waste and environmental impact. Borehole mining enhances material recovery by using high-pressure water jets to extract minerals selectively through boreholes, allowing precise excavation in inaccessible or underwater deposits.

Controlled Blasting

Controlled blasting in drilling and blasting techniques optimizes fragmentation and reduces environmental impact by precisely directing explosive energy, enhancing safety and operational efficiency in mining operations. Borehole mining, while minimally invasive and suitable for recovering minerals from submerged deposits, lacks the precision and scalability of controlled blasting for large-scale rock fragmentation.

Microseismic Monitoring

Drilling and blasting generate high-intensity vibrations detectable by microseismic monitoring systems, enabling precise assessment of rock fragmentation and stability during mining operations. Borehole mining produces lower amplitude seismic events, allowing microseismic techniques to effectively monitor subsurface cavity expansion and fluid pressure changes without causing extensive rock disturbance.

Borehole Hydraulic Mining

Borehole hydraulic mining uses high-pressure water jets to extract minerals through narrow boreholes, minimizing surface disruption compared to traditional drilling and blasting methods that create extensive fragmentation and environmental impact. This technique enhances precision in ore extraction, reduces ground vibrations, and allows access to deep or unstable deposits where conventional blasting poses safety risks.

Slot Drilling

Slot drilling in traditional drilling and blasting creates precise, narrow openings to control blast fragmentation and improve ore extraction efficiency, whereas borehole mining uses high-pressure jets to erode ore through boreholes, offering less initial fragmentation control but reducing surface disturbance. Slot drilling's ability to define blast patterns enhances fragmentation uniformity and material handling, making it a critical technique in conventional surface mining operations.

Multi-bench Blasting

Multi-bench blasting in traditional drilling and blasting techniques enhances fragmentation and reduces overall cycle time by simultaneously breaking multiple rock layers, optimizing production efficiency in surface mining operations. Borehole mining, while minimizing surface disruption and environmental impact through in-situ material extraction, lacks the high-volume rock removal capacity and precise bench control achievable with multi-bench blasting methods.

Water Jet Assisted Borehole Mining

Water Jet Assisted Borehole Mining enhances extraction by using high-pressure water jets to fragment ore, minimizing environmental impact and reducing the need for explosives compared to traditional drilling and blasting methods. This technique improves precision in ore recovery while lowering dust, vibration, and ground disturbance, making it a safer and more sustainable solution in mining operations.

Vibration Attenuation

Drilling and blasting generate high-intensity seismic vibrations causing extensive ground disturbance, while borehole mining produces minimal vibrations due to its controlled hydraulic excavation process. Vibration attenuation in borehole mining significantly reduces structural damage and environmental impact compared to the conventional explosive methods.

Cavity Monitoring System (CMS)

Drilling and blasting relies on explosive energy to fragment rock, while Borehole Mining employs high-pressure jets and slurry removal to extract minerals, with the Cavity Monitoring System (CMS) playing a critical role in optimizing cavity development and ensuring operational safety in borehole mining. CMS provides real-time imaging and data on cavity shape and growth, enabling precise control over mining parameters and minimizing geological risks compared to conventional drilling and blasting methods.

Fragmentation Analysis

Drilling and blasting in mining produces uneven fragmentation sizes due to explosive energy distribution, impacting ore handling and processing efficiency. Borehole mining offers more controlled fragmentation by using high-pressure water jets, enabling selective extraction and reducing the generation of fines and oversized particles.

Drilling and blasting vs Borehole mining Infographic

industrydif.com

industrydif.com