Heap leaching is a cost-effective mining technique involving the application of chemical solutions to heaps of crushed ore to extract valuable metals such as gold and copper. Phytomining, on the other hand, uses hyperaccumulator plants to absorb metals from contaminated soil, which are then harvested and processed to extract the metals, offering an eco-friendly alternative for metal recovery. While heap leaching is widely used in large-scale operations, phytomining presents a sustainable option for small-scale or environmentally sensitive mining sites.

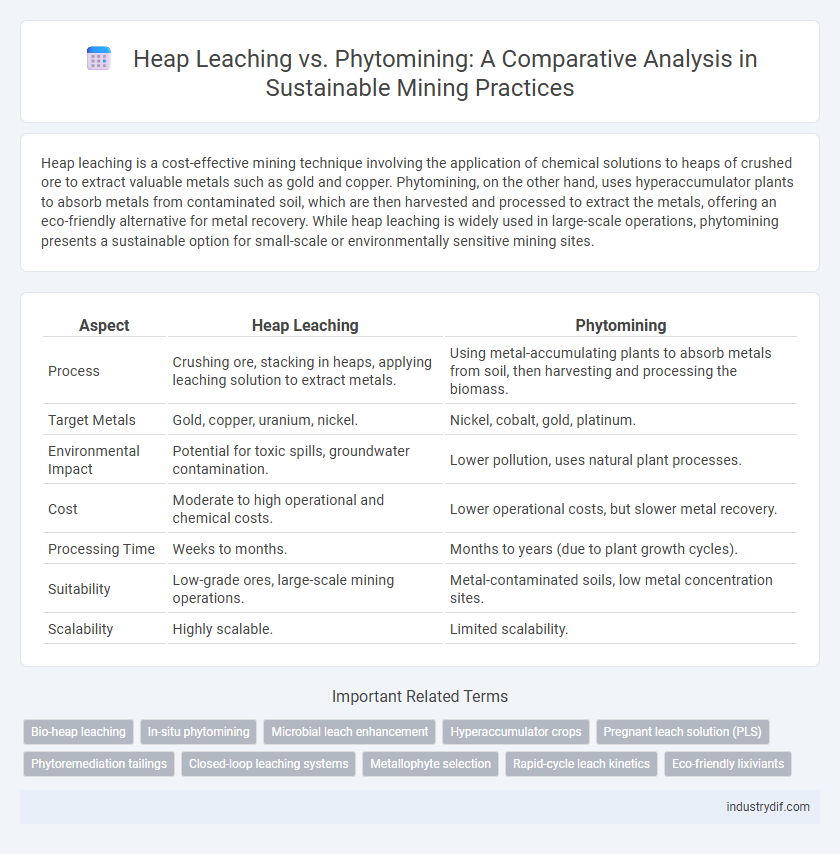

Table of Comparison

| Aspect | Heap Leaching | Phytomining |

|---|---|---|

| Process | Crushing ore, stacking in heaps, applying leaching solution to extract metals. | Using metal-accumulating plants to absorb metals from soil, then harvesting and processing the biomass. |

| Target Metals | Gold, copper, uranium, nickel. | Nickel, cobalt, gold, platinum. |

| Environmental Impact | Potential for toxic spills, groundwater contamination. | Lower pollution, uses natural plant processes. |

| Cost | Moderate to high operational and chemical costs. | Lower operational costs, but slower metal recovery. |

| Processing Time | Weeks to months. | Months to years (due to plant growth cycles). |

| Suitability | Low-grade ores, large-scale mining operations. | Metal-contaminated soils, low metal concentration sites. |

| Scalability | Highly scalable. | Limited scalability. |

Introduction to Heap Leaching and Phytomining

Heap leaching is an industrial mining process that extracts valuable metals from low-grade ores by stacking crushed ore and applying chemical solutions, typically cyanide or sulfuric acid, to dissolve metals like gold, copper, and uranium. Phytomining uses hyperaccumulator plants to absorb metals such as nickel and cobalt from contaminated soils, which are then harvested and processed to recover metals sustainably. Both techniques offer alternative metal extraction methods, with heap leaching favored for large-scale operations and phytomining providing eco-friendly prospects for metal recovery from low-concentration sources.

Overview of Extraction Processes

Heap leaching involves stacking ore and irrigating it with a leaching solution to dissolve valuable metals, which are then collected from the solution for further processing. Phytomining utilizes hyperaccumulator plants to absorb metals from soil during growth, which are harvested and incinerated to recover the metals from the ash. Both methods offer environmentally friendly alternatives for extracting metals like gold, copper, and nickel from low-grade ores or contaminated soils.

Applicable Metals and Ores

Heap leaching is widely applied to extract low-grade ores of gold, copper, and uranium by using chemical solutions to dissolve metals directly from crushed ore piles. Phytomining targets metals like nickel and cobalt, where hyperaccumulator plants absorb these metals from soil, making it suitable for contaminated or low-grade soils with specific metal content. Both methods offer eco-friendly alternatives, with heap leaching favoring sulfide and oxide ore types, while phytomining is limited to metals that plants can accumulate effectively.

Environmental Impact Comparison

Heap leaching involves stacking ore and applying chemical solvents to extract metals, which can pose risks of soil and water contamination due to chemical runoff. Phytomining uses hyperaccumulator plants to absorb metals from soil, offering a more eco-friendly alternative by minimizing chemical use and reducing habitat disruption. Environmental impact assessments indicate phytomining has a lower risk of toxic waste generation and better supports biodiversity compared to traditional heap leaching methods.

Operational Costs and Efficiency

Heap leaching operates with lower upfront capital costs and is highly efficient for extracting metals such as gold and copper from low-grade ores, leveraging percolation of leach solutions through ore heaps. Phytomining incurs higher operational costs due to the cultivation, harvesting, and processing of metal-accumulating plants, but it offers a sustainable approach for extracting nickel and cobalt from contaminated soils or low-grade deposits. Efficiency in heap leaching is generally higher with faster metal recovery rates, while phytomining is slower but provides environmental benefits by reducing soil pollution and preventing erosion.

Technological Advancements

Heap leaching and phytomining represent innovative extraction technologies that enhance metal recovery from low-grade ores and contaminated soils. Recent advancements in heap leaching include improved bacteria strains for bioleaching and optimized heap designs that increase leachate flow and metal yield. Phytomining has progressed with genetically engineered hyperaccumulators and advanced harvesting techniques that boost metal uptake efficiency and environmental sustainability.

Sustainability and Resource Recovery

Heap leaching offers a scalable and cost-effective method for extracting metals from low-grade ores using chemical solvents, enhancing resource recovery but raising environmental concerns due to potential cyanide usage. Phytomining leverages hyperaccumulator plants to absorb metals from soil, promoting sustainability by minimizing soil disruption and reducing chemical pollutants while enabling metal recovery from low-grade or contaminated sites. Integrating phytomining with traditional heap leaching techniques can optimize metal extraction efficiency and improve the ecological footprint of mining operations.

Challenges and Limitations

Heap leaching faces challenges such as environmental risks from chemical leachates and low recovery rates for certain metals, limiting its efficiency in complex ores. Phytomining struggles with slow biomass growth and metal accumulation rates, alongside geographic and climatic restrictions that affect plant survival and metal uptake. Both methods have scalability issues and site-specific limitations that impact their overall economic viability and environmental footprint.

Industry Case Studies

Heap leaching demonstrates significant efficiency in large-scale copper and gold mining operations, with industry giants like Freeport-McMoRan leveraging this method to maximize metal recovery from low-grade ores. Phytomining, applied in pilot projects such as those in the United Kingdom and South Africa, offers a sustainable alternative by extracting metals like nickel and gold through hyperaccumulator plants, reducing environmental impact and mining costs. Comparative analysis of case studies reveals heap leaching's dominance in high-volume metal extraction, while phytomining excels in eco-friendly applications and site rehabilitation.

Future Trends in Metal Extraction

Heap leaching and phytomining represent innovative approaches driving future trends in metal extraction by enhancing sustainability and cost-efficiency. Heap leaching optimizes metal recovery from low-grade ores through environmentally friendly solutions, while phytomining uses hyperaccumulator plants to extract metals from contaminated soils and mine tailings, enabling eco-friendly resource recovery. Advancements in biotechnology and green chemistry are expected to improve extraction rates and reduce environmental impacts, making these methods integral to future mining operations.

Related Important Terms

Bio-heap leaching

Bio-heap leaching combines microbial activity with traditional heap leaching to enhance the extraction of metals such as copper and gold from low-grade ores, improving recovery rates and reducing environmental impact compared to conventional methods. Phytomining utilizes hyperaccumulator plants to extract metals like nickel and cobalt from soil, offering a sustainable alternative but generally with slower metal recovery than bio-heap leaching techniques.

In-situ phytomining

Heap leaching enhances metal extraction by stacking ore and applying lixiviants to dissolve metals in situ, optimizing recovery from low-grade deposits. In-situ phytomining leverages hyperaccumulator plants grown directly on contaminated or low-grade soils to bioextract metals, offering an eco-friendly alternative with minimal environmental disturbance.

Microbial leach enhancement

Microbial leach enhancement in heap leaching involves using specific bacteria to accelerate metal recovery by oxidizing sulfide minerals, significantly improving extraction efficiency compared to conventional heap leaching methods. In contrast, phytomining relies on plants to uptake metals from soil, but its microbial interaction primarily facilitates bioavailability in the rhizosphere rather than directly enhancing metal solubilization like microbial heap leach processes.

Hyperaccumulator crops

Heap leaching involves extracting metals from low-grade ores by percolating chemical solutions, while phytomining uses hyperaccumulator crops such as Alyssum and Thlaspi to absorb metals like nickel and cobalt from soil. Hyperaccumulator plants concentrate metals in their biomass, offering an environmentally friendly and cost-effective alternative to traditional heap leaching for sustainable metal recovery.

Pregnant leach solution (PLS)

Pregnant leach solution (PLS) in heap leaching contains dissolved metals extracted from ore by acidic or alkaline solutions percolating through the heap, enabling efficient recovery of precious metals like gold and copper. In phytomining, PLS is not produced directly; instead, metal-rich biomass harvested from hyperaccumulator plants undergoes processing to extract metals, avoiding the need for chemical leachates.

Phytoremediation tailings

Phytomining leverages hyperaccumulator plants to extract valuable metals from mine tailings, offering a sustainable alternative to traditional heap leaching by minimizing chemical usage and environmental contamination. This phytoremediation method not only recovers metals such as nickel, copper, and gold but also stabilizes and detoxifies tailings, reducing the ecological footprint of mining operations.

Closed-loop leaching systems

Closed-loop leaching systems in heap leaching minimize environmental impact by recycling leachate and reducing chemical runoff, enhancing metal recovery efficiency. Phytomining, while sustainable by using hyperaccumulator plants to extract metals, lacks the scalability and closed-loop control present in heap leaching operations, making it less viable for large-scale mineral extraction.

Metallophyte selection

Metallophyte selection in phytomining targets hyperaccumulator plants that efficiently extract metals from soil, offering an eco-friendly method for metal recovery compared to heap leaching's chemical-intensive process. While heap leaching utilizes optimized ore particle sizes and chemical solutions to dissolve metals, phytomining emphasizes selecting metal-tolerant species to enhance bioaccumulation and reduce environmental impact.

Rapid-cycle leach kinetics

Heap leaching demonstrates rapid-cycle leach kinetics by efficiently extracting metals from low-grade ores through prolonged percolation of leach solutions, whereas phytomining relies on slower biological accumulation processes in hyperaccumulator plants, resulting in extended metal recovery times. The accelerated leach kinetics in heap leaching enable higher throughput and faster metal recovery compared to the gradual bioaccumulation and harvesting cycles inherent in phytomining.

Eco-friendly lixiviants

Heap leaching utilizes eco-friendly lixiviants such as cyanide alternatives and organic acids to minimize environmental impact during metal extraction from low-grade ores, whereas phytomining employs hyperaccumulator plants to bioabsorb metals, reducing the need for chemical lixiviants and lowering soil and water contamination risks. Both methods prioritize sustainable metal recovery, but phytomining offers enhanced biodegradability and lower toxicity compared to conventional heap leaching lixiviants.

Heap leaching vs Phytomining Infographic

industrydif.com

industrydif.com