Conveyor belt transport offers continuous, high-capacity movement of materials, making it ideal for long-distance mining operations with consistent workflow requirements. Rope conveyor systems provide greater flexibility in mountainous or uneven terrain where traditional belts face installation challenges, enabling efficient vertical and horizontal material transport. Choosing between these systems depends on terrain complexity, load capacity, and operational efficiency needs in mining applications.

Table of Comparison

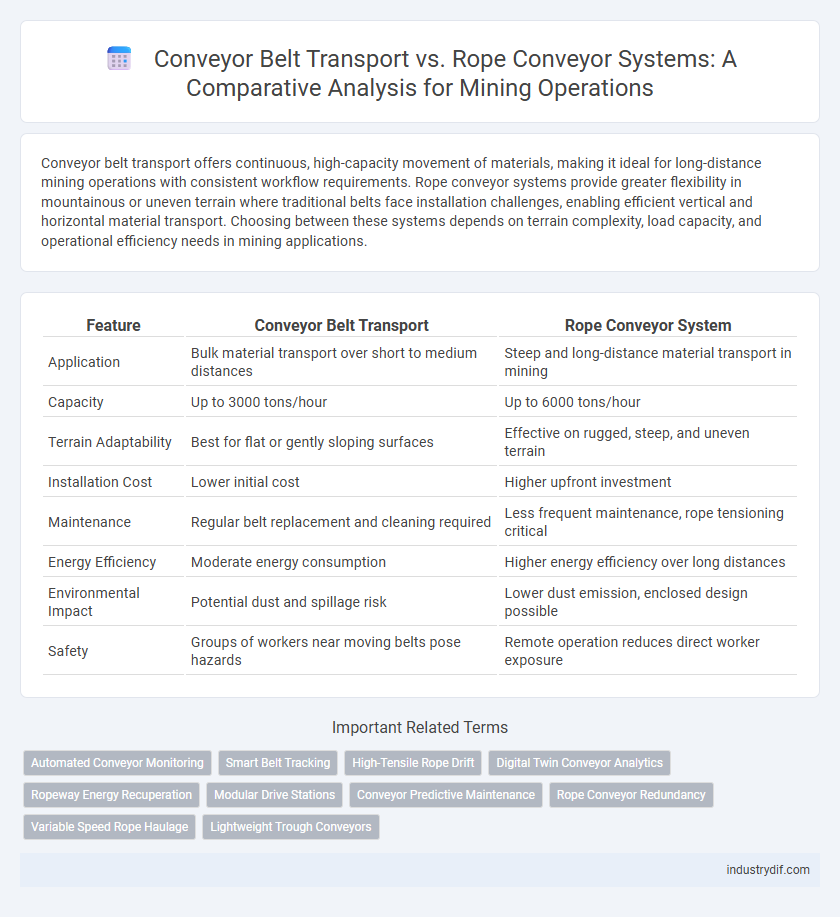

| Feature | Conveyor Belt Transport | Rope Conveyor System |

|---|---|---|

| Application | Bulk material transport over short to medium distances | Steep and long-distance material transport in mining |

| Capacity | Up to 3000 tons/hour | Up to 6000 tons/hour |

| Terrain Adaptability | Best for flat or gently sloping surfaces | Effective on rugged, steep, and uneven terrain |

| Installation Cost | Lower initial cost | Higher upfront investment |

| Maintenance | Regular belt replacement and cleaning required | Less frequent maintenance, rope tensioning critical |

| Energy Efficiency | Moderate energy consumption | Higher energy efficiency over long distances |

| Environmental Impact | Potential dust and spillage risk | Lower dust emission, enclosed design possible |

| Safety | Groups of workers near moving belts pose hazards | Remote operation reduces direct worker exposure |

Introduction to Material Handling in Mining

Conveyor belt transport in mining offers continuous, high-capacity movement of bulk materials across varied terrain, reducing labor intensity and operational costs. Rope conveyor systems excel in steep or rugged environments by enabling efficient uphill material transport with minimal environmental impact. Selecting between these systems requires analyzing factors such as load capacity, distance, gradient, and mine layout to optimize material handling efficiency.

Overview of Conveyor Belt Transport Systems

Conveyor belt transport systems in mining utilize continuous loops of durable materials to efficiently move bulk ores and materials over long distances with minimal human intervention. These systems are favored for their high capacity, energy efficiency, and ability to operate under harsh environmental conditions, providing a reliable solution for material handling. They consist of components such as pulleys, idlers, and motors designed to optimize load distribution and reduce maintenance downtime.

Overview of Rope Conveyor Systems

Rope conveyor systems in mining utilize wire ropes to move materials along suspended cables, offering high efficiency in rough terrains and long distances where traditional conveyor belts face limitations. These systems reduce environmental impact by enabling material transport over uneven topography without extensive ground infrastructure. Rope conveyors excel in steep gradients and areas prone to landslides, providing reliable, low-maintenance alternatives to conventional belt conveyors in mining operations.

Comparative Cost Analysis: Conveyor Belt vs Rope Conveyor

Conveyor belt transport typically incurs lower initial capital expenditure and offers reduced maintenance costs compared to rope conveyor systems, which require specialized components and more frequent inspections due to their complex cable mechanisms. Operating expenses for conveyor belts are generally more predictable, driven by energy consumption and routine belt replacement, whereas rope conveyors may involve higher energy costs due to cable tensioning and increased wear on pulleys. The overall cost-efficiency of conveyor belts makes them preferable for high-capacity, continuous mining operations, while rope conveyors may be justified in rugged, steep terrain despite their elevated lifecycle costs.

Energy Efficiency Comparison in Mining Operations

Conveyor belt transport in mining operations typically demonstrates higher energy efficiency due to its continuous material flow and lower friction losses compared to rope conveyor systems, which rely on suspended carriers and often consume more power to maintain tension and movement. Rope conveyor systems, while useful for steep or uneven terrain, generally exhibit higher specific energy consumption per ton of material transported because of increased mechanical complexity and maintenance demands. Evaluating energy usage metrics reveals conveyor belts as the preferred option for large-scale, energy-optimized mineral handling in flat to moderately inclined mining environments.

Maintenance Demands and Lifecycle

Conveyor belt transport systems require frequent maintenance due to belt wear, roller failures, and motor upkeep, typically resulting in a lifecycle of 10 to 15 years under heavy mining conditions. Rope conveyor systems exhibit lower maintenance demands with fewer moving parts and reduced mechanical stress, often extending their operational lifespan beyond 20 years. Selecting between these systems impacts long-term operational costs and downtime, with rope conveyors offering superior lifecycle advantages in abrasive environments.

Safety Considerations for Each System

Conveyor belt transport systems offer enhanced safety through automated controls and emergency stop mechanisms that reduce manual handling risks in mining operations. Rope conveyor systems require rigorous regular inspections and specialized training to manage load tension and prevent rope failures, ensuring stability on steep or uneven terrain. Both systems demand compliance with industry safety standards such as ISO 5048 and use of protective guards to minimize accident potential in harsh mining environments.

Adaptability to Challenging Terrains

Conveyor belt transport systems offer high adaptability in mining operations, efficiently handling varying loads and navigating curved or inclined pathways with ease. Rope conveyor systems excel in rugged and steep terrains where conventional belts may struggle, utilizing suspended carriers to bypass obstacles and maintain continuous material flow. Selecting the appropriate system depends on terrain complexity, load capacity, and operational flexibility required for specific mining environments.

Environmental Impact Assessment

Conveyor belt transport systems generate higher dust and noise pollution compared to rope conveyor systems, impacting surrounding ecosystems and air quality. Rope conveyors typically consume less energy and require fewer materials for installation, resulting in a smaller carbon footprint during operation and maintenance phases. Environmental Impact Assessments favor rope conveyor systems for their lower emissions, reduced habitat disturbance, and improved sustainability in mining operations.

Selecting the Optimal Transport Solution for Mining

Conveyor belt transport offers high capacity and continuous material flow, making it ideal for large-scale mining operations requiring efficient long-distance hauling. Rope conveyor systems excel in steep terrains and rugged environments by providing flexible routing and reduced ground impact, suited for complex mine topographies. Evaluating factors such as material type, mine layout, installation cost, and maintenance requirements is crucial for selecting the optimal transport solution in mining projects.

Related Important Terms

Automated Conveyor Monitoring

Automated conveyor monitoring systems in mining enhance operational efficiency by providing real-time data on conveyor belt transport, enabling predictive maintenance and reducing downtime. Rope conveyor systems benefit from integrated sensors that detect tension fluctuations and mechanical wear, ensuring safer and more reliable bulk material handling in complex terrain.

Smart Belt Tracking

Smart belt tracking in conveyor belt transport systems enhances operational efficiency by using sensors and AI to detect misalignment early, reducing downtime and maintenance costs. Rope conveyor systems lack this advanced tracking capability, making them less effective for precise load handling and real-time monitoring in mining operations.

High-Tensile Rope Drift

High-tensile rope drift systems in rope conveyor transport offer superior tensile strength and flexibility compared to traditional conveyor belt transport, enabling efficient movement of heavy loads over extended distances in mining operations. This advanced rope technology reduces maintenance costs and increases operational reliability in rugged mining environments where conveyor belts often face rapid wear and tear.

Digital Twin Conveyor Analytics

Digital Twin Conveyor Analytics enhances Conveyor Belt Transport by providing real-time monitoring and predictive maintenance through data-driven simulations, improving operational efficiency and reducing downtime. In contrast, Rope Conveyor Systems benefit from digital twin technology by optimizing load distribution and system resilience, enabling proactive adjustments to prevent mechanical failures in mining environments.

Ropeway Energy Recuperation

Rope conveyor systems in mining offer significant energy recuperation by harnessing the gravitational potential of descending loads, converting kinetic energy back into usable power, unlike conventional conveyor belt transport which primarily consumes energy without recovery. This regenerative capability enhances overall operational efficiency and reduces power costs in material transport across challenging terrains.

Modular Drive Stations

Modular drive stations in conveyor belt transport enable flexible power distribution and simplified maintenance, enhancing operational efficiency in mining environments. In contrast, rope conveyor systems rely on centralized drives, which can limit scalability and complicate system upgrades in large-scale mining operations.

Conveyor Predictive Maintenance

Conveyor belt transport systems require predictive maintenance strategies that leverage real-time sensor data and machine learning algorithms to detect belt wear, motor anomalies, and alignment issues before failures occur. Rope conveyor systems benefit from vibration monitoring and tension analysis to predict cable fatigue and drum misalignment, optimizing maintenance schedules and minimizing unplanned downtime in mining operations.

Rope Conveyor Redundancy

Rope conveyor systems offer superior redundancy compared to traditional conveyor belt transport by enabling multiple rope pathways that maintain operation even if one pathway fails, reducing downtime in mining operations. This redundancy enhances reliability in harsh mining environments, ensuring continuous material flow and minimizing maintenance interruptions.

Variable Speed Rope Haulage

Variable speed rope haulage systems in mining offer precise control over load movement, enhancing energy efficiency and reducing wear compared to traditional conveyor belt transport. These systems are particularly effective in steep or rugged terrains where conventional belts struggle, providing a versatile and reliable solution for material transport.

Lightweight Trough Conveyors

Lightweight trough conveyors offer enhanced efficiency and reduced energy consumption compared to traditional rope conveyor systems by utilizing lightweight materials and optimized trough designs for smooth bulk material transport. Their modular construction and low-maintenance requirements make them ideal for mining operations seeking cost-effective and scalable conveyor belt transport solutions.

Conveyor Belt Transport vs Rope Conveyor System Infographic

industrydif.com

industrydif.com