Block caving and sublevel cave mining are two underground mining techniques used to extract large volumes of ore efficiently. Block caving involves undermining an ore body, causing it to collapse and break under its own weight, which allows for continuous ore extraction but requires significant upfront development. Sublevel cave mining uses a series of horizontal levels to drill blasts that fragment the ore, offering more controlled extraction and better adaptability to varying ore body shapes.

Table of Comparison

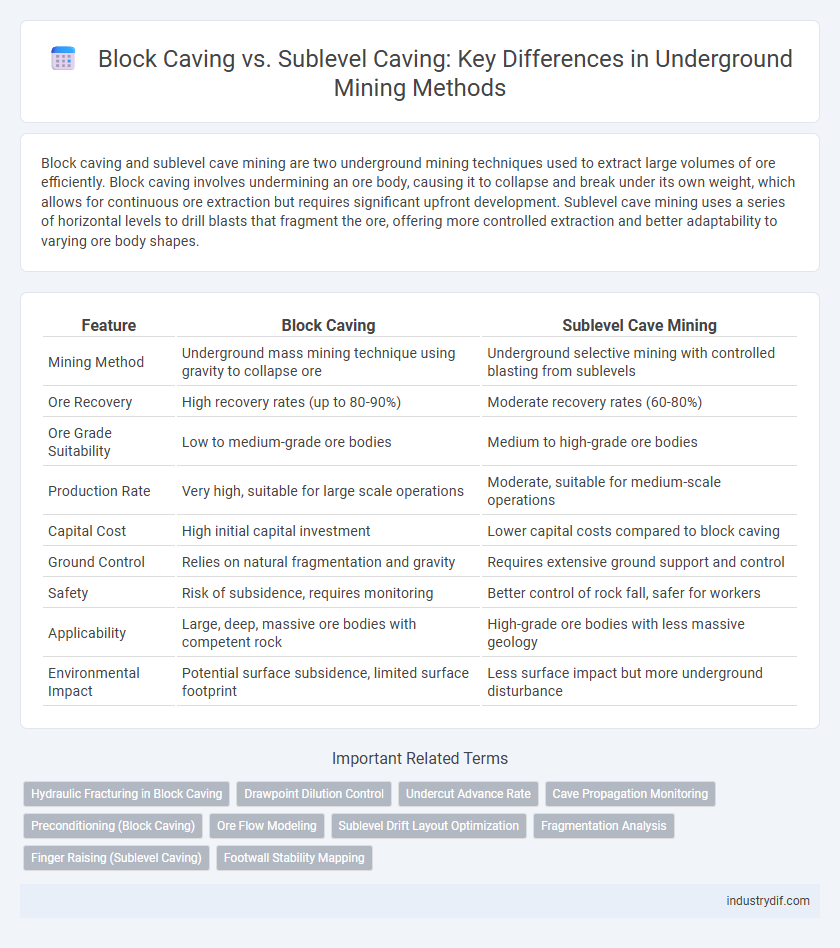

| Feature | Block Caving | Sublevel Cave Mining |

|---|---|---|

| Mining Method | Underground mass mining technique using gravity to collapse ore | Underground selective mining with controlled blasting from sublevels |

| Ore Recovery | High recovery rates (up to 80-90%) | Moderate recovery rates (60-80%) |

| Ore Grade Suitability | Low to medium-grade ore bodies | Medium to high-grade ore bodies |

| Production Rate | Very high, suitable for large scale operations | Moderate, suitable for medium-scale operations |

| Capital Cost | High initial capital investment | Lower capital costs compared to block caving |

| Ground Control | Relies on natural fragmentation and gravity | Requires extensive ground support and control |

| Safety | Risk of subsidence, requires monitoring | Better control of rock fall, safer for workers |

| Applicability | Large, deep, massive ore bodies with competent rock | High-grade ore bodies with less massive geology |

| Environmental Impact | Potential surface subsidence, limited surface footprint | Less surface impact but more underground disturbance |

Introduction to Block Caving and Sublevel Cave Mining

Block caving is an underground mining method that involves undermining a large ore body to cause it to collapse under its own weight, enabling efficient extraction of bulk ore. Sublevel cave mining combines drilling and blasting from multiple sublevels to fragment the ore, allowing controlled caving and optimized recovery. Both methods are suited for extracting low-grade, massive ore deposits with minimal environmental impact compared to traditional mining techniques.

Geological Suitability for Each Mining Method

Block caving is ideal for massive, low-grade ore bodies with strong, competent rock that can support large-scale cave propagation, commonly found in porphyry copper deposits. Sublevel cave mining suits more fractured or less competent rock masses where controlled cave progression is necessary to mitigate dilution, often applied in steeply dipping, high-grade gold or polymetallic orebodies. Geological conditions such as rock strength, ore body geometry, and fragmentation characteristics critically influence the selection between block caving and sublevel cave mining methods.

Block Caving: Principles and Process

Block caving is an underground mining method that exploits the natural fragmentation and gravity-induced caving of ore bodies, enabling extraction from large, low-grade deposits with high rock mass permeability. The process involves undercutting the ore block, causing it to collapse and break into fragments that can be collected from drawpoints below, optimizing mass mining efficiency. Effective application requires careful geotechnical analysis and a well-designed draw control system to manage fragmentation and ensure safety while maximizing ore recovery.

Sublevel Caving: Principles and Process

Sublevel caving involves creating horizontal sublevels in the ore body, where drilling and blasting induce controlled caving of the ore, allowing fragments to be extracted from drawpoints below. This method maximizes ore recovery by systematically undermining the rock mass, promoting fragmentation and gravity flow of broken material to collection points. Effective application depends on rock mass stability, ore body geometry, and careful sequencing to control ground movement and optimize production rates.

Ore Recovery and Dilution Rates Comparison

Block caving achieves higher ore recovery rates, often exceeding 70-85%, due to its controlled collapse mechanism that extracts large ore volumes efficiently. Sublevel cave mining typically exhibits lower ore recovery, around 60-75%, as selective extraction methods target ore in distinct sublevels, reducing overall resource extraction. Dilution rates in block caving tend to be higher, ranging from 15-30%, because of fragmented ore mixing with waste, whereas sublevel cave mining maintains comparatively lower dilution rates, generally between 10-20%, through more precise ore-waste separation.

Safety Considerations in Each Mining Method

Block caving offers improved safety by minimizing worker exposure to unstable ground, as most extraction occurs below the surface, reducing risks of rockfalls and collapses. Sublevel cave mining presents higher safety challenges due to frequent drilling and blasting activities conducted near mining personnel, increasing the likelihood of accidents. Effective ground control and continuous monitoring are crucial in both methods to mitigate hazards and ensure worker safety.

Equipment and Infrastructure Requirements

Block caving requires extensive and robust infrastructure, including large-scale ventilation systems, strong ground support, and automated haulage equipment to manage the continuous extraction of massive ore volumes. Sublevel cave mining demands more segmented and flexible equipment such as drill rigs, loaders, and trucks adapted for ore extraction in smaller, controlled sections, with less emphasis on large-scale ventilation. The equipment investment in block caving is generally higher due to the need for advanced automation and infrastructure to sustain large cave propagation and ore flow.

Cost Analysis: Capital and Operating Expenses

Block caving typically demands higher upfront capital investment due to extensive infrastructure requirements such as large-scale underground development and advanced ore handling systems. In contrast, sublevel cave mining incurs comparatively lower capital costs but often faces increased operating expenses driven by more frequent blasting, ventilation, and ore extraction activities. Operating costs for block caving can benefit from economies of scale, resulting in lower per-ton production costs when managing massive ore bodies over extended periods.

Environmental Impact Assessment

Block caving and sublevel cave mining differ significantly in environmental impact assessment due to their mining methods and surface disturbances. Block caving typically causes extensive subsidence and surface deformation, requiring thorough monitoring of land stability and potential effects on groundwater systems. Sublevel cave mining generates less surface subsidence but demands detailed evaluation of ventilation emissions and waste rock disposal to minimize air and water pollution risks.

Choosing the Right Method: Key Decision Factors

Selecting between block caving and sublevel cave mining hinges on orebody geometry, depth, and rock mass characteristics. Block caving suits large, massive orebodies with competent rock, enabling gravity-induced fragmentation, while sublevel cave mining is preferred for steeply dipping orebodies with variable rock stability. Economic factors such as production rate, capital expenditure, and operational flexibility critically influence the optimal method choice.

Related Important Terms

Hydraulic Fracturing in Block Caving

Hydraulic fracturing in block caving enhances rock fragmentation and permeability, allowing for efficient ore extraction from large, low-grade ore bodies with minimal ground support. This technique distinguishes block caving from sublevel cave mining by reducing fragmentation energy and facilitating controlled cave propagation.

Drawpoint Dilution Control

Drawpoint dilution control in block caving is optimized through controlled fragmentation and simultaneous extraction of multiple drawpoints, minimizing ore mixing and waste dilution. In sublevel cave mining, dilution control relies on strategic draw sequencing and isolated drawpoint management to reduce caving-induced dilution and maintain ore grade integrity.

Undercut Advance Rate

Block caving typically achieves faster undercut advance rates due to its reliance on gravity-induced rock breakage, enabling efficient large-scale ore extraction compared to the slower, more controlled undercutting in sublevel cave mining. The efficiency of undercut advance rate in block caving directly impacts production throughput and overall operational costs, making it a critical factor in mine planning and scheduling.

Cave Propagation Monitoring

Cave propagation monitoring in block caving utilizes microseismic and radar technologies to track caving progression and rock mass behavior, enabling precise control over fragmentation and subsidence. Sublevel cave mining employs less extensive monitoring due to its more controlled, staged extraction but still relies on geotechnical instruments to assess cave stability and adjust mining sequences.

Preconditioning (Block Caving)

Preconditioning in block caving involves drilling extensive blastholes and controlled blasting to fracture the orebody and surrounding rock, enhancing fragmentation and increasing caveability for efficient extraction. This process reduces seismic events and improves rock mass behavior, enabling safer and more predictable cave propagation compared to sublevel cave mining.

Ore Flow Modeling

Block caving offers a more continuous, gravity-driven ore flow with higher recovery rates due to its large-scale cave fragmentation, while sublevel caving requires carefully designed draw control to manage ore flow and minimize dilution. Ore flow modeling in block caving emphasizes predicting cave propagation and fragmentation patterns, whereas sublevel caving modeling focuses on optimizing drawpoints and scheduling to enhance ore extraction efficiency.

Sublevel Drift Layout Optimization

Sublevel drift layout optimization in sublevel cave mining enhances ore recovery and operational efficiency by strategically positioning drifts for improved fragmentation and haulage access. Compared to block caving, optimized sublevel drifts reduce dilution and enable better control over caving progression, resulting in increased production rates and lower costs.

Fragmentation Analysis

Block caving offers coarse fragmentation due to gravity-induced rock collapse, resulting in larger, uneven particle sizes that impact downstream processing efficiency, whereas sublevel cave mining produces finer and more uniform fragmentation by controlled blasting at various sublevels, enhancing ore fragmentation control and ore recovery rates. Fragmentation analysis in these methods is crucial for optimizing crusher design, minimizing dilution, and improving overall mine productivity and cost-effectiveness.

Finger Raising (Sublevel Caving)

Finger raising in sublevel caving enhances ore fragmentation and promotes controlled cave propagation by creating isolated extraction panels within the stope, improving safety and operational flexibility compared to block caving, which relies on large-scale mass extraction and cave initiation. This method optimizes ore recovery rates and reduces dilution by allowing selective extraction at sublevel intervals while managing ground stability effectively.

Footwall Stability Mapping

Block caving and sublevel cave mining differ significantly in footwall stability mapping, where block caving relies on extensive geotechnical data to predict large-scale mass movement and collapse patterns, ensuring safe extraction through controlled cave propagation. Sublevel cave mining requires more localized, high-resolution footwall stability assessments to manage smaller, more frequent drawpoints and maintain structural integrity around multiple sublevels.

Block caving vs Sublevel cave mining Infographic

industrydif.com

industrydif.com