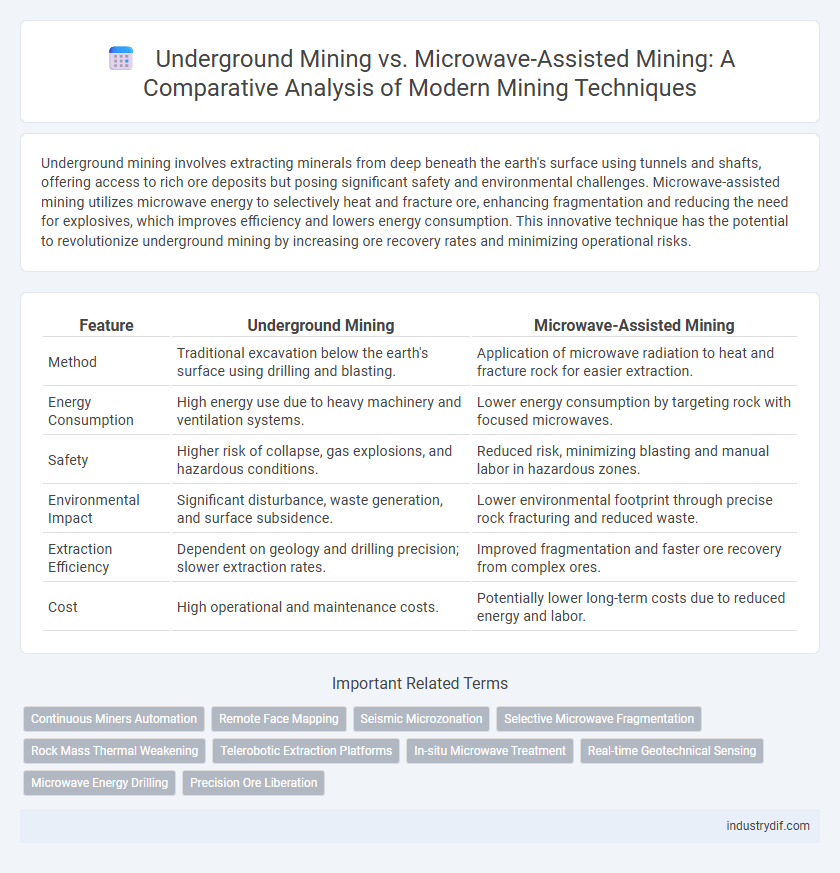

Underground mining involves extracting minerals from deep beneath the earth's surface using tunnels and shafts, offering access to rich ore deposits but posing significant safety and environmental challenges. Microwave-assisted mining utilizes microwave energy to selectively heat and fracture ore, enhancing fragmentation and reducing the need for explosives, which improves efficiency and lowers energy consumption. This innovative technique has the potential to revolutionize underground mining by increasing ore recovery rates and minimizing operational risks.

Table of Comparison

| Feature | Underground Mining | Microwave-Assisted Mining |

|---|---|---|

| Method | Traditional excavation below the earth's surface using drilling and blasting. | Application of microwave radiation to heat and fracture rock for easier extraction. |

| Energy Consumption | High energy use due to heavy machinery and ventilation systems. | Lower energy consumption by targeting rock with focused microwaves. |

| Safety | Higher risk of collapse, gas explosions, and hazardous conditions. | Reduced risk, minimizing blasting and manual labor in hazardous zones. |

| Environmental Impact | Significant disturbance, waste generation, and surface subsidence. | Lower environmental footprint through precise rock fracturing and reduced waste. |

| Extraction Efficiency | Dependent on geology and drilling precision; slower extraction rates. | Improved fragmentation and faster ore recovery from complex ores. |

| Cost | High operational and maintenance costs. | Potentially lower long-term costs due to reduced energy and labor. |

Introduction to Underground Mining

Underground mining involves extracting minerals from beneath the earth's surface through tunnels and shafts, allowing access to deep-seated ore deposits. This traditional method requires extensive ventilation, rock support, and safety measures to manage the challenging subterranean environment. Recent advancements like microwave-assisted mining aim to enhance efficiency by using targeted microwave energy to weaken rock structures, potentially reducing dependence on conventional blasting and excavation techniques.

Introduction to Microwave-Assisted Mining

Microwave-assisted mining leverages high-frequency electromagnetic waves to selectively heat rock formations, enhancing fragmentation and improving ore recovery compared to conventional underground mining methods. This innovative technology reduces energy consumption and environmental impact by minimizing explosives and mechanical excavation required. Its application promises higher efficiency, reduced operational costs, and safer mining environments in deep underground deposits.

Key Differences in Mining Techniques

Underground mining involves traditional excavation methods such as drilling, blasting, and hauling minerals from deep beneath the surface, relying heavily on physical labor and heavy machinery. Microwave-assisted mining uses targeted microwave energy to heat and fracture rock, reducing the need for explosives and mechanical equipment, which enhances energy efficiency and minimizes environmental impact. Key differences include operational complexity, energy consumption, and environmental footprint, with microwave-assisted mining offering a more precise and less invasive alternative to conventional underground mining.

Equipment Used in Underground and Microwave-Assisted Mining

Underground mining primarily utilizes equipment such as drill jumbos, continuous miners, shuttle cars, roof bolters, and ventilation systems designed to support excavation in confined subterranean environments. Microwave-assisted mining employs specialized microwave generators, waveguides, and applicators alongside conventional crushing and conveying machinery to induce rock fracturing through dielectric heating, reducing mechanical stress. The integration of microwave technology enhances energy efficiency and ore liberation compared to traditional underground mining methods reliant on heavy machinery and explosives.

Energy Consumption Comparison

Underground mining typically consumes high amounts of energy due to extensive excavation, ventilation, and material handling processes, often resulting in significant operational costs. Microwave-assisted mining reduces energy consumption by selectively heating and fracturing rock, which decreases mechanical drilling requirements and improves energy efficiency. Studies indicate microwave-assisted techniques can reduce energy usage by up to 30-40% compared to conventional underground mining methods.

Operational Safety Considerations

Underground mining presents significant operational safety risks including cave-ins, hazardous gas exposure, and limited emergency access, necessitating stringent ventilation and monitoring systems. Microwave-assisted mining enhances safety by reducing physical excavation, lowering the risk of collapse and harmful dust generation, while enabling remote operation that minimizes worker exposure to hazardous environments. Implementing microwave technology could revolutionize safety standards by mitigating common underground mining hazards through innovative, less invasive extraction techniques.

Economic Efficiency and Cost Analysis

Underground mining typically requires higher capital investment and ongoing operational costs related to ventilation, ground support, and labor-intensive extraction methods. Microwave-assisted mining reduces energy consumption and accelerates rock fragmentation, potentially lowering overall expenses and improving economic efficiency through decreased processing time and reduced equipment wear. Comparative cost analysis highlights that while initial technology adoption in microwave-assisted mining may be higher, long-term savings and productivity gains present significant financial advantages over traditional underground mining methods.

Environmental Impact Assessment

Underground mining generates significant environmental challenges including habitat disruption, groundwater contamination, and substantial greenhouse gas emissions from diesel equipment. Microwave-assisted mining offers a lower environmental footprint by reducing energy consumption and minimizing rock waste through precise heating, which decreases the need for explosives and mechanical drilling. Environmental Impact Assessments highlight reduced emissions and disturbance as key benefits, promoting microwave-assisted mining as a more sustainable alternative to traditional underground methods.

Productivity and Ore Recovery Rates

Underground mining typically achieves ore recovery rates between 70% and 90%, but faces productivity challenges due to labor intensity and safety constraints. Microwave-assisted mining enhances rock fragmentation by inducing thermal cracks, significantly improving efficiency and potentially increasing ore recovery rates by up to 15%. This innovative technology reduces energy consumption and operational downtime, resulting in higher throughput and overall productivity compared to traditional underground methods.

Future Trends in Mining Technologies

Underground mining continues to evolve with innovations like automation and remote operation, improving safety and efficiency in deeper and more challenging ore bodies. Microwave-assisted mining represents a transformative technology, using targeted microwave energy to selectively fragment rock, reducing energy consumption and environmental impact compared to conventional blasting. Future trends emphasize hybrid approaches, integrating microwave-assisted techniques with traditional underground methods to enhance ore recovery while minimizing operational costs and ecological footprint.

Related Important Terms

Continuous Miners Automation

Continuous miners in underground mining enhance operational efficiency by mechanizing ore extraction and reducing manual labor, while microwave-assisted mining offers a novel, energy-efficient method for rock fragmentation through targeted electromagnetic waves that minimize blasting requirements and improve safety. Automation in continuous mining systems integrates advanced sensors and AI-driven controls, increasing precision, reducing downtime, and enabling remote operation, whereas microwave-assisted techniques remain in experimental stages with potential for future automated integration to further optimize mining productivity and sustainability.

Remote Face Mapping

Underground mining relies on traditional geological surveys and manual face mapping, which can be time-consuming and less precise in complex ore bodies. Microwave-assisted mining integrates remote face mapping technologies such as laser scanning and real-time data analytics, enhancing accuracy in ore characterization and improving operational safety in subterranean environments.

Seismic Microzonation

Seismic microzonation in underground mining enhances risk assessment by mapping localized seismic hazards, improving the stability and safety of tunnels. Microwave-assisted mining reduces seismic disturbances by targeting mineral bonds with electromagnetic energy, minimizing vibrations compared to traditional blasting methods.

Selective Microwave Fragmentation

Selective microwave fragmentation in underground mining enhances ore extraction by precisely targeting mineralized zones, reducing waste and energy consumption compared to traditional blasting methods. This innovative technique leverages microwave energy to weaken rock structures selectively, improving fragmentation efficiency and minimizing environmental impact in subterranean operations.

Rock Mass Thermal Weakening

Microwave-assisted mining enhances rock mass thermal weakening by inducing rapid internal heating, which reduces rock strength and facilitates fracture propagation more efficiently than conventional underground mining methods. This targeted thermal approach minimizes mechanical stress and energy consumption, improving overall excavation speed and safety in hard rock environments.

Telerobotic Extraction Platforms

Telerobotic extraction platforms in underground mining significantly enhance safety and efficiency by enabling remote operation in hazardous environments, reducing human exposure to dangerous conditions. Microwave-assisted mining integrated with telerobotic systems improves ore fragmentation by selectively heating rock, accelerating extraction processes while minimizing energy consumption and environmental impact.

In-situ Microwave Treatment

In-situ microwave treatment in underground mining utilizes targeted microwave energy to fracture and weaken ore bodies, enhancing efficiency and reducing environmental impact compared to conventional blasting methods. This innovative approach decreases energy consumption and minimizes ground vibrations, significantly improving safety and ore recovery rates in subterranean mining operations.

Real-time Geotechnical Sensing

Underground mining integrates real-time geotechnical sensing technologies such as seismic monitoring and ground-penetrating radar to detect rock stability and prevent collapses, ensuring miner safety and operational efficiency. Microwave-assisted mining enhances real-time geotechnical sensing by enabling precise subsurface imaging and material characterization through microwave tomography, which improves ore detection and reduces environmental impact.

Microwave Energy Drilling

Microwave energy drilling in underground mining enhances fragmentation by using high-frequency electromagnetic waves to induce thermal stress, resulting in faster rock breakage compared to conventional mechanical methods. This innovative approach reduces energy consumption, minimizes equipment wear, and improves operational safety by eliminating the need for explosive charges in difficult-to-access underground environments.

Precision Ore Liberation

Underground mining offers traditional bulk extraction but struggles with selective precision ore liberation, often leading to increased dilution and lower recovery rates. Microwave-assisted mining enhances precision by selectively fracturing ore at the mineral boundaries, improving liberation efficiency and reducing waste rock processing.

Underground mining vs Microwave-assisted mining Infographic

industrydif.com

industrydif.com