Strip mining involves removing large strips of surface soil and rock to access minerals, making it efficient for extracting shallow mineral deposits but often causing significant environmental disruption. Precision mining utilizes advanced technologies like GPS and drones to target mineral deposits accurately, minimizing waste and reducing environmental impact. This method enhances resource recovery and operational efficiency by carefully managing extraction to preserve surrounding ecosystems.

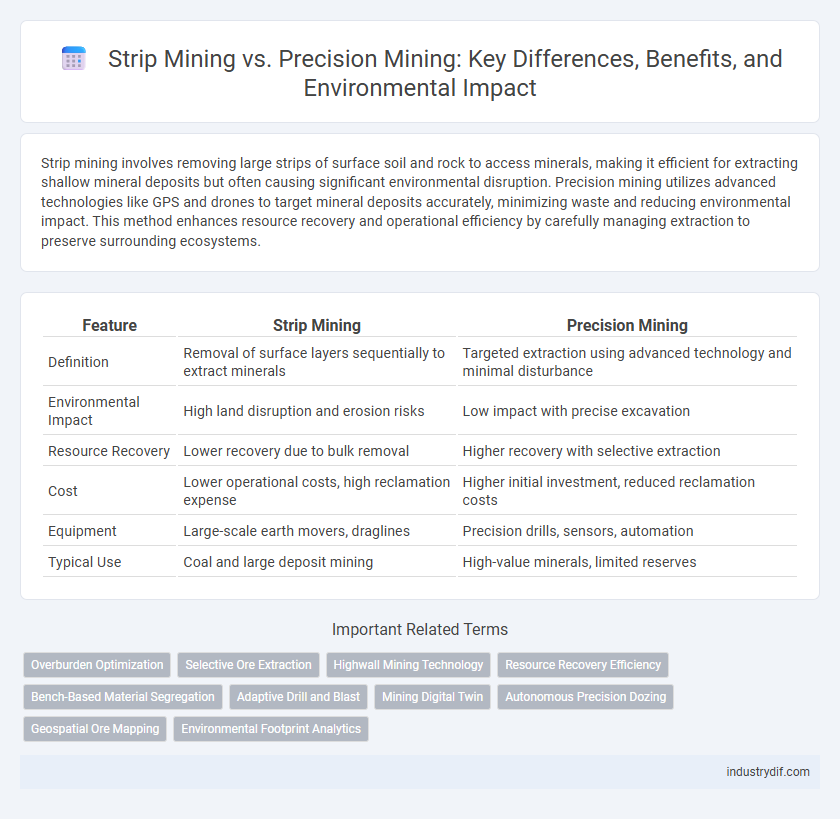

Table of Comparison

| Feature | Strip Mining | Precision Mining |

|---|---|---|

| Definition | Removal of surface layers sequentially to extract minerals | Targeted extraction using advanced technology and minimal disturbance |

| Environmental Impact | High land disruption and erosion risks | Low impact with precise excavation |

| Resource Recovery | Lower recovery due to bulk removal | Higher recovery with selective extraction |

| Cost | Lower operational costs, high reclamation expense | Higher initial investment, reduced reclamation costs |

| Equipment | Large-scale earth movers, draglines | Precision drills, sensors, automation |

| Typical Use | Coal and large deposit mining | High-value minerals, limited reserves |

Introduction to Mining Techniques

Strip mining involves removing large surface layers to access mineral seams, making it suitable for shallow, extensive deposits such as coal or phosphate. Precision mining employs advanced technology like drones and sensors to target ore selectively, minimizing waste and environmental impact, ideal for valuable, concentrated deposits. Both methods prioritize efficiency, but precision mining enhances resource recovery and reduces ecological disruption compared to traditional strip mining.

Defining Strip Mining

Strip mining involves the systematic removal of large surface layers of soil and rock to expose underlying mineral deposits, primarily used for coal and other sedimentary minerals. This method efficiently extracts resources over vast, shallow deposits by sequentially stripping elongated sections, minimizing waste material movement compared to random excavation. Precision mining, in contrast, targets specific ore bodies with advanced technologies, reducing environmental impact and increasing resource recovery rates.

Defining Precision Mining

Precision mining utilizes advanced technologies such as GPS, drones, and data analytics to target mineral extraction accurately, minimizing waste and environmental impact compared to traditional strip mining. While strip mining involves large-scale removal of surface layers, precision mining emphasizes selective extraction based on real-time data to optimize resource recovery. This method enhances operational efficiency and sustainability, reducing land disturbance and reclamation costs significantly.

Historical Development of Mining Methods

Strip mining originated in the early 20th century as an efficient technique for extracting shallow, horizontal mineral deposits, particularly coal, using large-scale earth-moving equipment. Precision mining emerged later with advancements in technology, emphasizing targeted extraction through methods like drilling and blasting to minimize environmental impact and maximize resource recovery. The historical development of these methods reflects a shift from bulk removal strategies to more sustainable and precise approaches in the mining industry.

Key Differences: Strip Mining vs Precision Mining

Strip mining involves removing large surface areas of soil and rock to extract minerals, leading to significant environmental disruption and waste generation. Precision mining uses advanced technologies like GPS and sensors to target specific mineral deposits, minimizing land disturbance and improving resource efficiency. Key differences include environmental impact, operational accuracy, and resource recovery rates, with precision mining offering a more sustainable and cost-effective approach.

Environmental Impact Comparison

Strip mining causes significant environmental degradation by removing vast surface areas, leading to deforestation, habitat destruction, and soil erosion. Precision mining targets specific mineral deposits using advanced technology, minimizing land disturbance and reducing waste generation. This targeted approach results in lower emissions, less water contamination, and improved ecosystem preservation compared to traditional strip mining methods.

Economic Efficiency and Output

Strip mining offers high economic efficiency in large-scale operations due to lower initial costs and faster resource extraction, making it suitable for shallow mineral deposits. Precision mining maximizes output quality and reduces waste by targeting specific ore bodies, resulting in higher profitability per ton despite higher operational expenses. The choice between these methods depends on deposit depth, ore grade, and long-term cost-benefit analysis.

Technological Advancements in Precision Mining

Precision mining leverages advanced technologies such as drones, GPS mapping, and automated machinery to minimize environmental impact and increase extraction accuracy compared to traditional strip mining. Innovations in real-time data analytics and sensor integration optimize resource identification and reduce waste, enhancing operational efficiency. These technological advancements enable targeted excavation, preserving surrounding ecosystems while maximizing ore recovery rates.

Safety Considerations and Worker Welfare

Strip mining poses significant safety risks such as ground collapses and exposure to hazardous materials, impacting worker welfare due to its large-scale environmental disturbances. Precision mining enhances safety by targeting specific mineral deposits, reducing the likelihood of accidents and minimizing workers' exposure to harmful conditions. Advanced technologies in precision mining contribute to improved emergency response and monitoring, fostering a safer work environment for mining personnel.

Future Trends in Mining Practices

Future trends in mining emphasize a shift from traditional strip mining to precision mining techniques, driven by advancements in geospatial data analytics and automated machinery. Precision mining reduces environmental impact by targeting ore deposits more accurately, minimizing waste and land disturbance compared to the extensive excavation required in strip mining. Integration of AI and remote sensing technologies further enhances resource efficiency and supports sustainable mining practices.

Related Important Terms

Overburden Optimization

Strip mining involves removing large volumes of overburden indiscriminately, often resulting in excessive waste and environmental disturbance, whereas precision mining employs advanced technologies to optimize overburden removal, minimizing waste and reducing ecological impact. Overburden optimization in precision mining enhances resource recovery efficiency by precisely targeting mineral deposits and reducing excavation of unnecessary material.

Selective Ore Extraction

Selective ore extraction in strip mining involves removing large surface layers, often leading to significant waste and environmental disruption, whereas precision mining targets specific ore bodies with minimal waste, enhancing resource efficiency and reducing ecological impact. Precision mining employs advanced technologies like geospatial mapping and real-time sensors to accurately isolate high-grade ore, optimizing yield and lowering operational costs compared to conventional strip mining methods.

Highwall Mining Technology

Highwall mining technology integrates elements of strip mining and precision mining by enabling selective extraction along exposed coal seams with minimal surface disturbance. This method increases resource recovery efficiency while reducing environmental impact compared to traditional strip mining practices.

Resource Recovery Efficiency

Strip mining extracts vast surface layers, often resulting in lower resource recovery efficiency due to extensive waste and environmental disruption. Precision mining targets specific ore deposits with advanced technologies, maximizing resource recovery and minimizing material loss and environmental impact.

Bench-Based Material Segregation

Bench-based material segregation in strip mining enables large-scale removal of overburden and ore in distinct horizontal layers, optimizing resource extraction while minimizing dilution costs. Precision mining uses advanced sensors and real-time data to selectively extract ore from specific benches, enhancing grade control and reducing waste compared to traditional strip mining techniques.

Adaptive Drill and Blast

Adaptive Drill and Blast technology enhances precision mining by optimizing blast patterns to minimize ore loss and reduce environmental impact compared to traditional strip mining methods. Employing real-time data analytics and automated drilling, this approach increases resource recovery and operational efficiency in surface mining operations.

Mining Digital Twin

Mining Digital Twin technology enhances precision mining by providing real-time data analytics and predictive modeling, leading to optimized resource extraction and reduced environmental impact. Compared to traditional strip mining, this digital innovation enables accurate resource mapping and efficient operational planning, significantly improving safety and cost-effectiveness in mining processes.

Autonomous Precision Dozing

Autonomous Precision Dozing in strip mining enhances efficiency by using GPS-guided equipment to remove overburden with minimal environmental impact, reducing waste compared to traditional broad-strip methods. This technology optimizes material removal precisely, increasing productivity while preserving surrounding land and lowering operational costs.

Geospatial Ore Mapping

Strip mining relies on large-scale excavation with less emphasis on precise ore boundaries, often leading to substantial overburden removal and environmental disruption. Precision mining utilizes advanced geospatial ore mapping technologies such as 3D modeling and hyperspectral imaging to accurately delineate ore bodies, optimizing extraction efficiency and minimizing waste.

Environmental Footprint Analytics

Strip mining results in extensive land disturbance and higher environmental footprints due to large-scale soil removal and habitat destruction, impacting biodiversity and water quality. Precision mining employs targeted extraction techniques and real-time environmental footprint analytics, minimizing waste and reducing ecological damage through optimized resource use and lower emissions.

Strip mining vs Precision mining Infographic

industrydif.com

industrydif.com