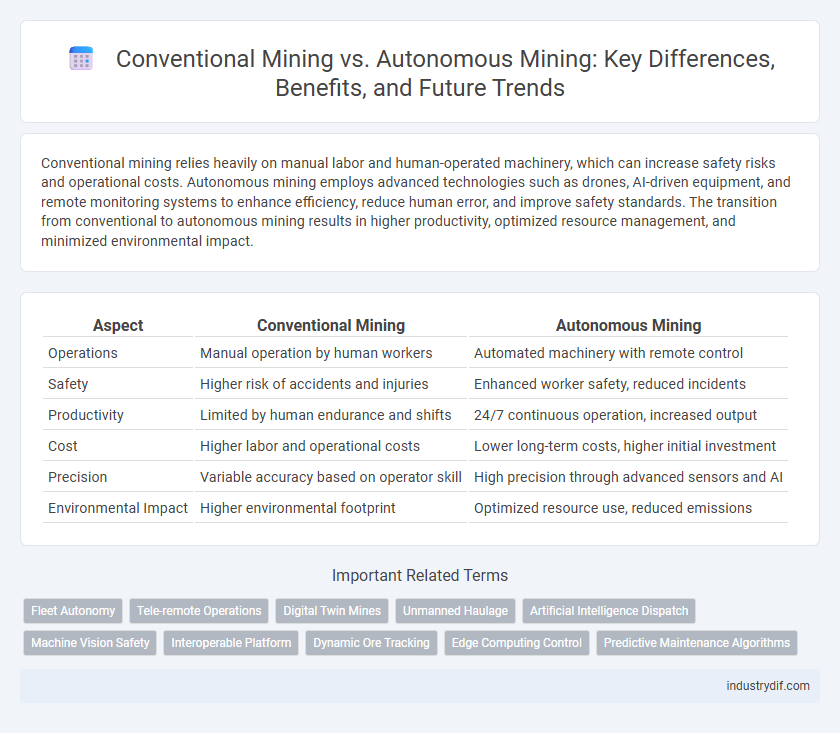

Conventional mining relies heavily on manual labor and human-operated machinery, which can increase safety risks and operational costs. Autonomous mining employs advanced technologies such as drones, AI-driven equipment, and remote monitoring systems to enhance efficiency, reduce human error, and improve safety standards. The transition from conventional to autonomous mining results in higher productivity, optimized resource management, and minimized environmental impact.

Table of Comparison

| Aspect | Conventional Mining | Autonomous Mining |

|---|---|---|

| Operations | Manual operation by human workers | Automated machinery with remote control |

| Safety | Higher risk of accidents and injuries | Enhanced worker safety, reduced incidents |

| Productivity | Limited by human endurance and shifts | 24/7 continuous operation, increased output |

| Cost | Higher labor and operational costs | Lower long-term costs, higher initial investment |

| Precision | Variable accuracy based on operator skill | High precision through advanced sensors and AI |

| Environmental Impact | Higher environmental footprint | Optimized resource use, reduced emissions |

Introduction to Conventional and Autonomous Mining

Conventional mining relies heavily on manual labor and human-operated machinery for excavation and material transport, which often results in slower production rates and higher safety risks. Autonomous mining employs advanced technologies such as AI-driven vehicles, drones, and automated drilling systems to increase efficiency, reduce operational costs, and enhance worker safety. The integration of autonomous systems in mining operations leads to real-time data monitoring, improved precision, and optimized resource extraction compared to traditional methods.

Key Technologies in Autonomous Mining

Autonomous mining leverages advanced technologies such as artificial intelligence, machine learning, and remote sensing to enhance operational efficiency and safety compared to conventional mining methods. Key technologies include autonomous haulage systems (AHS), drone surveying, and real-time data analytics, enabling precise resource extraction and minimizing human intervention. Integration of IoT sensors and robotics further optimizes equipment maintenance and reduces downtime in autonomous mining operations.

Operational Efficiency: Manual Versus Automated Systems

Conventional mining relies on manual operation of heavy machinery, which often results in slower cycle times and higher operational costs due to human error and fatigue. Autonomous mining systems utilize advanced sensors, AI, and robotics to optimize equipment utilization, reduce downtime, and increase extraction rates with consistent precision. Studies show that automated mining increases operational efficiency by up to 30%, improving safety while lowering energy consumption and maintenance expenses.

Safety Standards in Conventional vs Autonomous Mining

Conventional mining relies heavily on human labor, exposing workers to hazardous environments and increasing the risk of accidents and injuries, with safety standards focusing on personal protective equipment and supervised operations. Autonomous mining integrates advanced technologies like AI-driven machinery and remote monitoring systems, significantly reducing human presence in dangerous zones and thus minimizing workplace accidents and health hazards. Enhanced safety protocols in autonomous mining leverage real-time data analytics and automated emergency responses, creating safer operational conditions compared to traditional methods.

Environmental Impact Comparison

Conventional mining generates significant environmental disruption through extensive land disturbance, high energy consumption, and increased greenhouse gas emissions due to heavy machinery and manual operations. Autonomous mining reduces environmental impact by optimizing precision excavation, lowering fuel consumption with electric or hybrid vehicles, and minimizing habitat destruction through advanced sensor technologies. Data from recent industry studies indicate autonomous systems can cut carbon emissions by up to 30% and enhance resource efficiency, resulting in a more sustainable mining process.

Cost Analysis: Labor, Equipment, and Maintenance

Conventional mining incurs higher labor costs due to extensive manual operations and shift requirements, whereas autonomous mining significantly reduces labor expenses by deploying automated machinery and remote monitoring systems. Equipment costs in autonomous mining initially are elevated due to advanced technology investments but are offset by enhanced operational efficiency and longer asset lifespans compared to traditional machinery. Maintenance expenses in autonomous mining benefit from predictive analytics and real-time diagnostics, leading to lower downtime and lower repair costs relative to conventional mining's reactive maintenance approach.

Workforce Implications and Skills Requirements

Conventional mining relies heavily on manual labor, requiring a workforce skilled in equipment operation, maintenance, and safety protocols, often in hazardous environments. Autonomous mining integrates advanced robotics, AI, and data analytics, shifting workforce demands toward technical expertise in systems management, programming, and remote operations. This transition reduces physical labor needs but increases the necessity for continuous training in digital skills and cybersecurity to manage and maintain autonomous systems effectively.

Data Analytics and Decision-Making in Modern Mining

Conventional mining relies heavily on manual data collection and human-driven decision-making, often leading to slower response times and increased safety risks. Autonomous mining integrates advanced data analytics and real-time sensor data to optimize operational efficiency, enabling faster, data-driven decisions with enhanced precision. The implementation of machine learning algorithms in autonomous systems significantly improves predictive maintenance and resource allocation, transforming modern mining operations.

Case Studies: Success Stories and Challenges

Case studies in conventional mining highlight consistent production rates and established safety protocols but reveal limitations in efficiency and workforce risks. Autonomous mining projects, such as Rio Tinto's AutoHaul and Komatsu's autonomous trucks, demonstrate significant improvements in operational efficiency, reduced labor costs, and enhanced safety, though challenges remain in high initial investment and technological adaptation. Success stories emphasize optimized resource extraction and real-time data analytics, while ongoing challenges include system integration and cybersecurity concerns.

Future Trends in Mining Automation

Future trends in mining automation emphasize the shift from conventional mining methods to fully autonomous systems that enhance safety, efficiency, and productivity. Autonomous mining equipment, including driverless trucks and robotic drills, reduces human error and operational costs while enabling continuous 24/7 operation in harsh environments. Integration of artificial intelligence, machine learning, and real-time data analytics drives predictive maintenance and optimizes resource extraction, setting new standards for the mining industry's sustainable growth.

Related Important Terms

Fleet Autonomy

Fleet autonomy in autonomous mining significantly enhances operational efficiency by enabling real-time data integration, remote monitoring, and automated decision-making, reducing human intervention and increasing safety. Conventional mining relies heavily on manual vehicle operation, limiting productivity and responsiveness compared to the scalable, AI-driven fleet management systems used in autonomous mining.

Tele-remote Operations

Conventional mining relies on manual labor and on-site operation, exposing workers to hazardous conditions and limiting operational efficiency. Autonomous mining integrates tele-remote operations, enabling operators to control equipment from safe, remote locations, enhancing safety, reducing downtime, and increasing productivity in mining processes.

Digital Twin Mines

Digital Twin Mines revolutionize conventional mining by creating real-time virtual replicas of physical operations, enabling precise monitoring and predictive maintenance to enhance efficiency and safety. Autonomous mining leverages these digital twins for automated decision-making and remote control, significantly reducing downtime and operational costs while improving resource extraction accuracy.

Unmanned Haulage

Conventional mining relies on manned haulage trucks operated by drivers, which increases labor costs and safety risks, while autonomous mining utilizes unmanned haulage systems that improve operational efficiency, reduce downtime, and enhance safety by minimizing human exposure to hazardous environments. The integration of autonomous haulage vehicles (AHVs) in mining operations leads to optimized fleet management, lower fuel consumption, and increased productivity through real-time data analytics and remote control capabilities.

Artificial Intelligence Dispatch

Artificial Intelligence Dispatch in autonomous mining optimizes equipment allocation and real-time decision-making, boosting operational efficiency and reducing human error compared to conventional mining, which relies heavily on manual coordination and slower communication processes. This AI-driven system improves resource management and minimizes downtime, leading to increased productivity and cost savings in mining operations.

Machine Vision Safety

Machine vision safety in autonomous mining significantly reduces human exposure to hazardous environments by enabling real-time hazard detection and automated emergency responses, compared to conventional mining where manual monitoring increases risk. The integration of advanced sensors and AI-driven image analysis in autonomous systems enhances operational safety by continuously identifying potential equipment failures, ground instability, and worker presence.

Interoperable Platform

Conventional mining relies on manual operations with limited integration across equipment and systems, resulting in fragmented data flows and reduced efficiency. Autonomous mining employs interoperable platforms that enable seamless communication between machines, real-time data analytics, and coordinated workflows, enhancing productivity and safety in mining operations.

Dynamic Ore Tracking

Dynamic ore tracking in autonomous mining leverages real-time sensor data and AI algorithms to accurately map ore bodies, enhancing extraction precision and reducing waste compared to conventional mining methods. Conventional mining relies on static geological models and periodic sampling, which often leads to less efficient ore recovery and increased operational costs.

Edge Computing Control

Conventional mining relies heavily on manual operations with centralized control systems that often cause delays in data processing and decision-making. Autonomous mining leverages edge computing control to process data locally on-site, enabling real-time monitoring, faster responses, and improved operational efficiency.

Predictive Maintenance Algorithms

Predictive maintenance algorithms in autonomous mining utilize real-time data and machine learning to anticipate equipment failures, significantly reducing unplanned downtime compared to conventional mining's reliance on scheduled inspections. Enhanced sensor integration and AI-driven analytics enable autonomous systems to optimize equipment health monitoring, increasing operational efficiency and safety in mining operations.

Conventional Mining vs Autonomous Mining Infographic

industrydif.com

industrydif.com