Conventional mining relies heavily on excavation and physical extraction methods that often result in significant environmental disruption and high energy consumption. Microbial mining, on the other hand, uses microorganisms to bioleach metals from ores, offering a more sustainable and cost-effective alternative with reduced ecological impact. This innovative approach enables the recovery of valuable metals from low-grade ores and mining waste, improving resource efficiency and minimizing pollution.

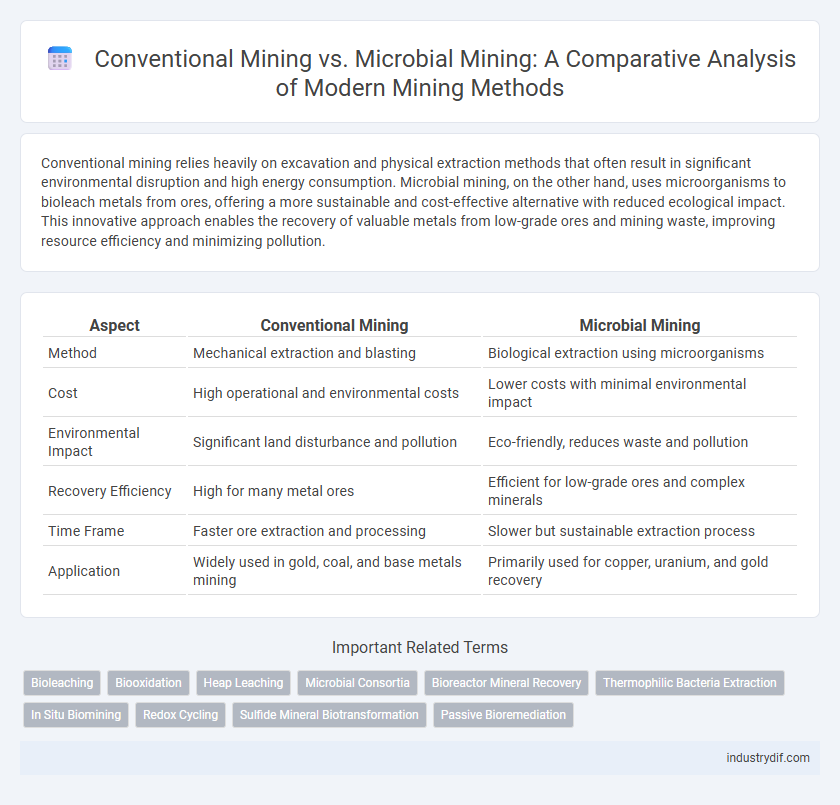

Table of Comparison

| Aspect | Conventional Mining | Microbial Mining |

|---|---|---|

| Method | Mechanical extraction and blasting | Biological extraction using microorganisms |

| Cost | High operational and environmental costs | Lower costs with minimal environmental impact |

| Environmental Impact | Significant land disturbance and pollution | Eco-friendly, reduces waste and pollution |

| Recovery Efficiency | High for many metal ores | Efficient for low-grade ores and complex minerals |

| Time Frame | Faster ore extraction and processing | Slower but sustainable extraction process |

| Application | Widely used in gold, coal, and base metals mining | Primarily used for copper, uranium, and gold recovery |

Overview of Conventional Mining Techniques

Conventional mining techniques primarily involve physical extraction methods such as open-pit mining, underground mining, and placer mining, which rely on heavy machinery and explosives to access ore deposits. These methods often result in significant environmental disruption, including habitat destruction and soil erosion, while generating large quantities of waste rock and tailings. Despite their efficiency in obtaining high-grade ores, conventional mining faces challenges related to energy consumption, operational costs, and environmental impact management.

Introduction to Microbial Mining

Microbial mining leverages microorganisms to extract valuable metals from ores, offering an environmentally friendly alternative to conventional mining techniques that rely on physical and chemical processes. This biotechnological approach enhances metal recovery efficiency by oxidizing sulfide minerals and mobilizing metals through bioleaching and biooxidation methods. Industrial applications of microbial mining include copper, gold, and uranium extraction, reducing energy consumption and minimizing toxic byproduct generation compared to traditional smelting and roasting operations.

Key Differences Between Conventional and Microbial Mining

Conventional mining relies on mechanical extraction techniques including drilling, blasting, and hauling, which often result in significant environmental disruption and high energy consumption. Microbial mining, also known as biomining, utilizes microorganisms to bioleach metals from ores, offering a more eco-friendly and cost-effective alternative by reducing waste and emissions. Key differences include the efficiency of metal recovery, operational scale, environmental impact, and process duration, with microbial mining favoring sustainable extraction of low-grade ores.

Efficiency and Resource Recovery in Mining Methods

Conventional mining relies on mechanical and chemical processes that often result in high energy consumption and lower resource recovery rates due to ore dilution and loss during extraction. Microbial mining, or biomining, uses microorganisms to bioleach metals from ores, achieving higher efficiency by targeting low-grade ores and reducing environmental impact through minimal chemical use. Resource recovery in microbial mining is enhanced by the microorganisms' ability to selectively solubilize metals, leading to more sustainable and cost-effective metal extraction compared to traditional methods.

Environmental Impacts: Conventional vs Microbial Mining

Conventional mining generates significant environmental impacts including landscape disruption, habitat destruction, and extensive water contamination from chemical runoff and tailings. In contrast, microbial mining employs bioleaching techniques using microorganisms to extract metals, drastically reducing the need for toxic chemicals and minimizing soil and water pollution. This eco-friendly approach lowers greenhouse gas emissions and promotes sustainable resource recovery in comparison to traditional mining methods.

Cost Comparison: Traditional Mining vs Bioleaching

Traditional mining incurs high operational costs due to intensive labor, heavy machinery, and extensive excavation processes. Microbial mining, specifically bioleaching, significantly reduces expenses by utilizing naturally occurring microorganisms to extract metals from ores with minimal energy and equipment requirements. Cost efficiency in bioleaching stems from lower capital investment and reduced environmental remediation expenses compared to conventional mining methods.

Safety Considerations in Mining Operations

Conventional mining operations often present significant safety hazards such as exposure to toxic chemicals, risk of cave-ins, and respiratory issues from dust inhalation. Microbial mining reduces these risks by utilizing microorganisms to extract metals, minimizing the need for explosive methods and harmful chemicals. This bioleaching approach enhances worker safety and reduces environmental contamination associated with traditional mining techniques.

Applications and Limitations of Microbial Mining

Microbial mining leverages microorganisms to extract metals such as copper, gold, and uranium from low-grade ores and mining waste, offering a sustainable alternative to conventional mining techniques that rely on physical and chemical processes. Its applications include bioleaching in metal recovery and bioremediation of contaminated mining sites, which reduce environmental impact and operational costs. However, microbial mining faces limitations such as slower extraction rates, sensitivity to environmental conditions, and challenges in scaling up for large volume mineral processing.

Current Industry Adoption and Case Studies

Conventional mining remains the dominant method for extracting minerals due to its established technology and high recovery rates, widely applied in large-scale operations such as the Grasberg mine in Indonesia. Microbial mining, also known as bioleaching, is gaining traction in niche sectors by leveraging bacteria like Acidithiobacillus ferrooxidans to extract metals from low-grade ores, demonstrated by successful case studies at the Escondida copper mine in Chile. Industry adoption of microbial mining is expanding as companies seek environmentally sustainable alternatives, yet conventional methods continue to lead in overall production volume and infrastructure investment.

Future Trends in Mining Technology

Future trends in mining technology prioritize sustainability and efficiency, with microbial mining gaining traction as a low-impact alternative to conventional methods. Microbial mining utilizes bacteria and archaea to extract metals from ores through bioleaching and biooxidation, reducing environmental footprints compared to traditional blasting and excavation. Innovations in genetic engineering and bioprocess optimization are expected to enhance recovery rates and expand the range of extractable minerals, positioning microbial mining as a key driver in the evolution of eco-friendly resource extraction.

Related Important Terms

Bioleaching

Bioleaching in microbial mining utilizes specialized bacteria such as Acidithiobacillus ferrooxidans to extract metals from ores by oxidizing sulfides, enhancing metal recovery efficiency while reducing environmental impact compared to conventional mining techniques. Conventional mining typically involves physical extraction and chemical processing methods that generate significant waste and require high energy input, whereas bioleaching offers a cost-effective and eco-friendly alternative for obtaining metals like copper, gold, and uranium.

Biooxidation

Biooxidation in microbial mining utilizes specialized bacteria to efficiently break down sulfide minerals, enhancing metal recovery while reducing environmental impact compared to conventional mining methods that rely on physical and chemical processes. This biotechnological approach improves extraction from low-grade ores, minimizes energy consumption, and lowers greenhouse gas emissions.

Heap Leaching

Heap leaching in conventional mining relies on chemical reagents such as cyanide to extract metals from ores, while microbial mining utilizes bioleaching bacteria like Acidithiobacillus ferrooxidans to enhance metal recovery through natural biochemical processes. Microbial heap leaching offers improved environmental sustainability and cost efficiency by reducing toxic chemical usage and accelerating metal solubilization in low-grade ores.

Microbial Consortia

Microbial consortia in microbial mining enhance metal recovery by utilizing synergistic interactions among diverse microorganisms to oxidize and leach ores more efficiently than conventional mining methods. These consortia improve bioleaching rates, reduce environmental impact, and enable extraction from low-grade ores that are otherwise uneconomical for traditional mining techniques.

Bioreactor Mineral Recovery

Conventional mining relies on physical and chemical processes to extract minerals, often involving energy-intensive methods and significant environmental disruption. Bioreactor mineral recovery in microbial mining leverages specific microorganisms within controlled bioreactors to enhance metal solubilization and extraction efficiency, reducing ecological impact and operational costs.

Thermophilic Bacteria Extraction

Conventional mining relies on physical and chemical methods to extract minerals, often causing environmental degradation and high energy consumption. Thermophilic bacterial extraction in microbial mining uses heat-tolerant microorganisms to bioleach metals from ores at elevated temperatures, offering a more sustainable and efficient alternative.

In Situ Biomining

Conventional mining involves large-scale excavation and physical extraction of minerals from ore deposits, often causing significant environmental disruption. In situ biomining utilizes microbes to bioleach metals directly within the ore body underground, minimizing surface disturbance and enabling efficient recovery of valuable metals such as copper, gold, and uranium.

Redox Cycling

Conventional mining relies on physical and chemical extraction methods, whereas microbial mining leverages microorganisms to facilitate redox cycling processes that oxidize metal sulfides, enhancing metal recovery efficiency. Redox cycling in microbial mining accelerates the transformation of metal sulfides into soluble metal ions, reducing environmental impact compared to traditional smelting and roasting techniques.

Sulfide Mineral Biotransformation

Conventional mining relies on physical and chemical methods to extract sulfide minerals, often causing environmental degradation, whereas microbial mining utilizes specific bacteria to biooxidize sulfide minerals, enhancing metal recovery with reduced ecological impact. Sulfide mineral biotransformation through microbial oxidation accelerates metal solubilization, enabling efficient extraction of valuable metals like copper and gold from refractory ores.

Passive Bioremediation

Conventional mining relies heavily on physical extraction methods that often result in significant environmental disruption and the generation of toxic waste, whereas microbial mining utilizes microorganisms to biologically extract metals and passively remediate contaminated sites by breaking down pollutants naturally. Passive bioremediation in microbial mining leverages indigenous bacteria and fungi to detoxify acid mine drainage and heavy metals without energy-intensive interventions, offering a sustainable and cost-effective alternative to traditional remediation techniques.

Conventional Mining vs Microbial Mining Infographic

industrydif.com

industrydif.com