Mineral processing involves traditional techniques such as crushing, grinding, and flotation to extract valuable minerals from ore, often requiring significant energy and water consumption. Sensor-based ore sorting offers a more selective approach by using technologies like X-ray, near-infrared, or electromagnetic sensors to identify and separate valuable particles from waste rock before processing, reducing overall throughput and costs. This method enhances efficiency and sustainability by minimizing waste and optimizing downstream mineral processing operations.

Table of Comparison

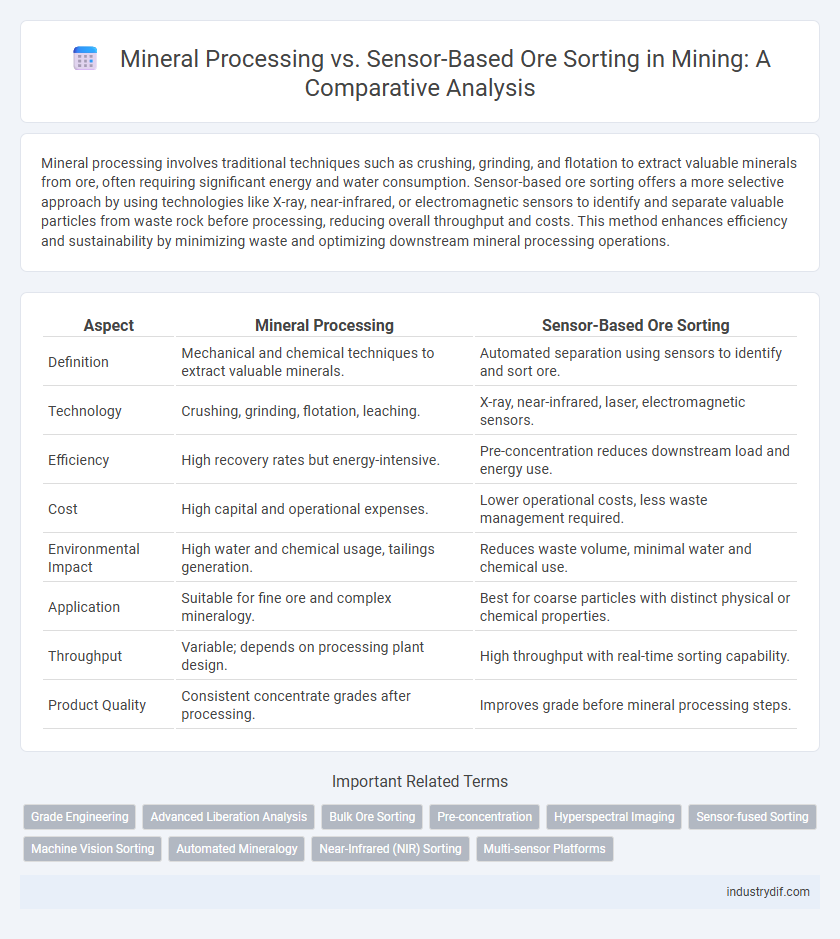

| Aspect | Mineral Processing | Sensor-Based Ore Sorting |

|---|---|---|

| Definition | Mechanical and chemical techniques to extract valuable minerals. | Automated separation using sensors to identify and sort ore. |

| Technology | Crushing, grinding, flotation, leaching. | X-ray, near-infrared, laser, electromagnetic sensors. |

| Efficiency | High recovery rates but energy-intensive. | Pre-concentration reduces downstream load and energy use. |

| Cost | High capital and operational expenses. | Lower operational costs, less waste management required. |

| Environmental Impact | High water and chemical usage, tailings generation. | Reduces waste volume, minimal water and chemical use. |

| Application | Suitable for fine ore and complex mineralogy. | Best for coarse particles with distinct physical or chemical properties. |

| Throughput | Variable; depends on processing plant design. | High throughput with real-time sorting capability. |

| Product Quality | Consistent concentrate grades after processing. | Improves grade before mineral processing steps. |

Introduction to Mineral Processing and Sensor-Based Ore Sorting

Mineral processing involves the physical and chemical techniques used to liberate valuable minerals from ore, optimizing extraction efficiency and concentrating minerals for further refining. Sensor-based ore sorting employs advanced detection technologies such as X-ray, optical, and electromagnetic sensors to identify and separate ore particles based on their mineralogical properties before processing. Integrating sensor-based sorting with traditional mineral processing enhances feed grade, reduces waste, and improves overall plant performance by selectively removing low-grade or waste material early in the production cycle.

Key Principles of Mineral Processing

Mineral processing relies on physical and chemical properties such as density, particle size, and surface chemistry to separate valuable minerals from ore, using techniques like crushing, grinding, flotation, and magnetic separation. Sensor-based ore sorting employs advanced imaging technologies, including X-ray transmission, near-infrared spectroscopy, and laser-induced breakdown spectroscopy, to identify and separate ore particles based on specific mineral characteristics in real-time. Both methods aim to improve ore grade and recovery rates, but mineral processing focuses on bulk separation, while sensor-based sorting targets selective removal of waste materials before further processing.

Fundamentals of Sensor-Based Ore Sorting

Sensor-based ore sorting utilizes advanced detection technologies such as X-ray, near-infrared, and electromagnetic sensors to identify and separate valuable minerals from waste rock based on physical and chemical properties. This method enhances ore grade early in the mineral processing chain by selectively removing low-value materials, thus reducing overall energy consumption and increasing throughput efficiency. Sensor-based sorting fundamentally improves resource utilization by targeting specific ore characteristics, enabling more precise and cost-effective upstream beneficiation compared to traditional bulk mineral processing techniques.

Key Differences Between Traditional Mineral Processing and Sensor-Based Sorting

Traditional mineral processing relies heavily on physical and chemical methods such as crushing, grinding, flotation, and gravity separation to extract valuable minerals from ore, often requiring significant energy and water usage. Sensor-based ore sorting uses advanced technologies like X-ray, near-infrared, and laser sensors to identify and separate ore particles based on their physical or chemical properties before further processing, enhancing efficiency and reducing waste. Key differences include the selective pre-concentration capability of sensor-based sorting, lower operational costs, and reduced environmental impact compared to conventional mineral processing techniques.

Advantages of Sensor-Based Ore Sorting Technologies

Sensor-based ore sorting technologies enhance mining efficiency by selectively separating high-grade ore from waste, reducing energy consumption and operational costs. These advanced sorting systems improve metal recovery rates and minimize environmental impact by limiting the volume of material sent to downstream processing. Integration of real-time data analytics with sensor technologies enables precise ore characterization, optimizing resource utilization and maximizing profitability.

Limitations and Challenges of Sensor-Based Ore Sorting

Sensor-based ore sorting faces limitations including difficulties in accurately detecting fine-grained or complex mineral phases and challenges with heterogeneous ore compositions that reduce sorting precision. The technology often struggles with high throughput requirements due to the need for rapid, real-time data processing, which can lead to compromised sorting accuracy. Environmental factors like dust, moisture, and variable lighting conditions further challenge sensor reliability and consistent performance in harsh mining environments.

Comparative Analysis: Efficiency and Cost

Mineral processing involves conventional techniques like crushing, grinding, and flotation, offering high recovery rates but with significant energy consumption and operational costs. Sensor-based ore sorting uses advanced technologies such as X-ray, infrared, or induction sensors to selectively separate ore from waste, reducing energy usage and processing volumes. While sensor-based sorting lowers upfront and operational expenses, mineral processing remains more efficient for complex ores with finer liberation requirements.

Environmental Impact: Traditional vs Sensor-Based Methods

Mineral processing often involves energy-intensive crushing, grinding, and chemical treatments that generate significant waste and water pollution, contributing to a larger environmental footprint. Sensor-based ore sorting reduces the volume of material processed by identifying and separating valuable minerals early, leading to lower energy consumption, less chemical usage, and decreased tailings production. This technology enables more sustainable mining practices by minimizing environmental disturbances and promoting resource efficiency.

Industrial Applications and Case Studies

Mineral processing and sensor-based ore sorting are critical technologies in modern mining, with industrial applications enhancing efficiency and reducing costs. Sensor-based ore sorting utilizes X-ray, near-infrared, or laser sensors to selectively separate ore from waste, demonstrated in case studies like the Mt. Isa copper mine, where pre-concentration improved throughput and recovery rates. Mineral processing, involving crushing, grinding, and flotation, remains essential for fine particle beneficiation, with case studies highlighting operations at the Grasberg mine showcasing significant increases in metal grade and environmental sustainability.

Future Trends in Mineral Processing and Ore Sorting Innovations

Future trends in mineral processing emphasize integrating sensor-based ore sorting technologies to enhance efficiency and reduce operational costs. Advanced sensors such as X-ray transmission (XRT), near-infrared (NIR), and laser-induced breakdown spectroscopy (LIBS) enable precise separation of valuable minerals from waste, improving recovery rates and ore grade. The development of machine learning algorithms combined with real-time data analytics optimizes sorting accuracy, supports sustainable mining practices, and drives next-generation mineral beneficiation methods.

Related Important Terms

Grade Engineering

Mineral processing involves traditional methods such as crushing, grinding, and flotation to separate valuable minerals based on physical and chemical properties, optimizing recovery and concentrate grade. Sensor-based ore sorting enhances grade engineering by using real-time data from X-ray, near-infrared, or electromagnetic sensors to selectively remove low-grade material before milling, reducing energy consumption and increasing overall process efficiency.

Advanced Liberation Analysis

Advanced Liberation Analysis enhances mineral processing by providing detailed insights into ore mineral associations and grain sizes, enabling more precise separation techniques. Sensor-based ore sorting leverages this data to selectively separate valuable minerals from waste, improving recovery rates and reducing processing costs.

Bulk Ore Sorting

Bulk ore sorting enhances mineral processing efficiency by pre-concentrating low-grade ore, reducing the volume fed to crushers and mills. Sensor-based technologies, such as X-ray transmission and near-infrared sensors, enable real-time discrimination of valuable minerals from waste, optimizing resource recovery and lowering energy consumption.

Pre-concentration

Sensor-based ore sorting enhances pre-concentration by accurately separating valuable minerals from low-grade ore, reducing processing volumes and energy consumption. Mineral processing relies on physical and chemical methods, but sensor-based sorting improves efficiency by targeting valuable fractions before traditional beneficiation.

Hyperspectral Imaging

Hyperspectral imaging in sensor-based ore sorting enhances mineral processing by rapidly identifying and segregating valuable minerals based on their spectral signatures, reducing waste and energy consumption. This technology enables precise, real-time analysis of ore composition, improving the efficiency and sustainability of mining operations compared to traditional mineral processing methods.

Sensor-fused Sorting

Sensor-fused sorting integrates multiple sensor technologies such as X-ray transmission (XRT) and near-infrared (NIR) to enhance ore grade separation, reducing waste and increasing recovery rates compared to traditional mineral processing methods. This advanced technique offers precise, real-time analysis of ore characteristics, optimizing feed quality and lowering operational costs in mining operations.

Machine Vision Sorting

Machine vision sorting in mineral processing leverages advanced image analysis and pattern recognition algorithms to enhance ore grade and reduce waste by accurately identifying valuable minerals from gangue. Compared to traditional sensor-based sorting techniques, machine vision offers higher spatial resolution and real-time adaptability, improving sorting precision and operational efficiency in mineral beneficiation.

Automated Mineralogy

Automated mineralogy integrates advanced imaging and spectroscopy techniques for precise characterization of ore minerals, enhancing efficiency in both mineral processing and sensor-based ore sorting by enabling accurate liberation analysis and grade control. Sensor-based ore sorting leverages real-time data to segregate valuable minerals from waste, reducing energy consumption and improving downstream processing, while automated mineralogy provides critical insights that optimize these sorting algorithms and processing workflows.

Near-Infrared (NIR) Sorting

Near-Infrared (NIR) sorting in sensor-based ore sorting offers a precise, energy-efficient alternative to traditional mineral processing by using spectral data to differentiate minerals based on their chemical composition and moisture content. This technology enhances recovery rates and reduces waste by selectively sorting ore particles, leading to lower operational costs and improved overall efficiency in mining operations.

Multi-sensor Platforms

Multi-sensor platforms integrate technologies such as X-ray transmission, near-infrared spectroscopy, and laser-induced breakdown spectroscopy to enhance sensor-based ore sorting accuracy, enabling efficient separation of valuable minerals from waste. Mineral processing traditionally relies on physical and chemical methods, while sensor-based ore sorting with multi-sensor systems reduces energy consumption and operational costs by pre-concentrating ore before downstream processing.

Mineral processing vs Sensor-based ore sorting Infographic

industrydif.com

industrydif.com