Drill and blast mining involves drilling holes into rock formations, filling them with explosives, and detonating to fragment the rock for easier extraction, making it highly effective for hard rock environments. Cut and fill mining is a selective underground method where ore is extracted in horizontal slices, and the voids are filled with waste materials or tailings, improving ground stability and safety in weak rock conditions. Comparing both, drill and blast offers higher productivity for large-scale operations, while cut and fill provides greater precision and control, suitable for irregular ore bodies and minimizing dilution.

Table of Comparison

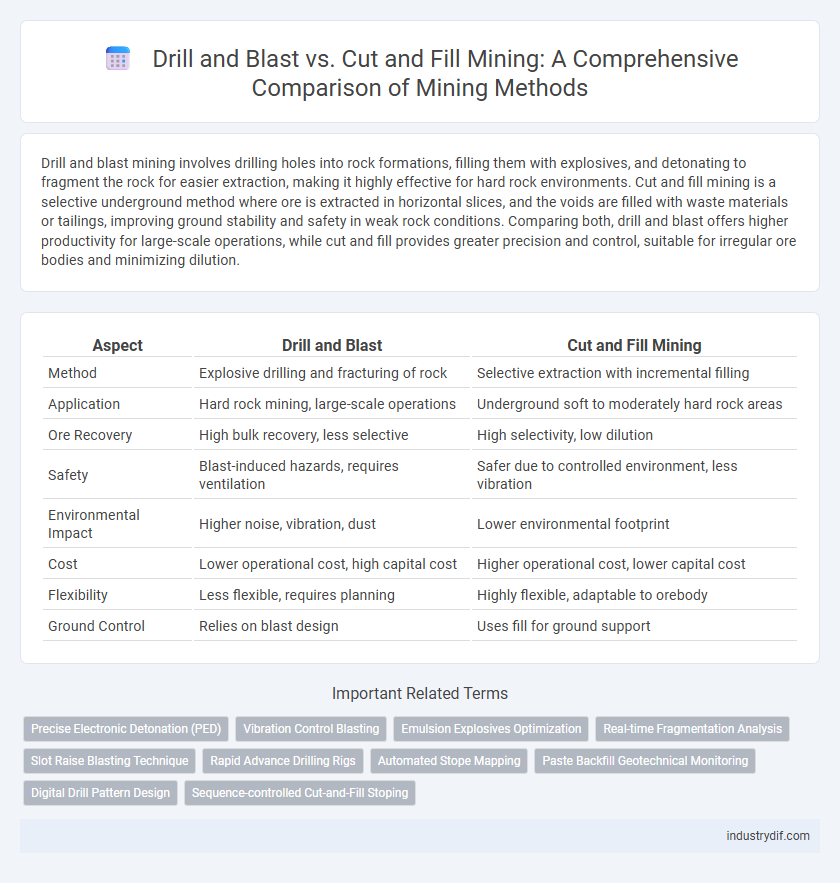

| Aspect | Drill and Blast | Cut and Fill Mining |

|---|---|---|

| Method | Explosive drilling and fracturing of rock | Selective extraction with incremental filling |

| Application | Hard rock mining, large-scale operations | Underground soft to moderately hard rock areas |

| Ore Recovery | High bulk recovery, less selective | High selectivity, low dilution |

| Safety | Blast-induced hazards, requires ventilation | Safer due to controlled environment, less vibration |

| Environmental Impact | Higher noise, vibration, dust | Lower environmental footprint |

| Cost | Lower operational cost, high capital cost | Higher operational cost, lower capital cost |

| Flexibility | Less flexible, requires planning | Highly flexible, adaptable to orebody |

| Ground Control | Relies on blast design | Uses fill for ground support |

Overview of Drill and Blast Mining

Drill and blast mining involves drilling holes into the rock face, inserting explosives, and detonating them to fragment the rock for easier removal. This method is widely used in hard rock mining due to its efficiency in breaking large volumes of ore and waste rock. It offers precise control over rock fragmentation and is often preferred for large-scale operations requiring high production rates.

Introduction to Cut and Fill Mining

Cut and fill mining is a selective underground mining method that involves excavating ore in horizontal slices, starting from the bottom of the ore body and advancing upwards. This technique allows for efficient ore extraction while maintaining ground stability by filling the voids with waste material or tailings after each slice is removed. It is especially suited for irregular or steeply dipping ore bodies and provides better control over ore dilution compared to drill and blast methods.

Key Differences Between Drill and Blast vs Cut and Fill

Drill and blast mining involves drilling holes into rock, inserting explosives, and blasting to fragment the rock for removal, making it suitable for large-scale, hard rock mining operations. Cut and fill mining is a selective underground mining method where ore is excavated in horizontal slices and backfilled with waste material, providing greater ground support and safety in irregular ore bodies. The key differences lie in their operational scale, fragmentation technique, and ground control, with drill and blast emphasizing bulk extraction, while cut and fill prioritizes precision and minimized dilution.

Geological Suitability for Each Method

Drill and blast mining is ideal for stable rock formations with predictable fracture patterns, allowing efficient fragmentation and reducing waste. Cut and fill mining suits irregular or weak geological conditions, providing better ground support and adaptability in complex ore bodies. Choosing the appropriate method depends heavily on rock strength, stability, and ore body geometry to maximize safety and extraction efficiency.

Equipment and Technology Used

Drill and blast mining employs heavy-duty rotary drills and explosive charges to fracture rock, utilizing advanced blast design software and electronic detonators for precision and safety. Cut and fill mining relies on mechanized loaders, backhoes, and grizzlies to excavate and backfill with waste or tailings, incorporating conveyor systems and backfill placement technology to enhance fill compaction and ground support. Both methods utilize automation and real-time monitoring systems to improve efficiency and equipment utilization in underground operations.

Environmental Impacts and Considerations

Drill and blast mining generates significant dust, noise, and vibrations that can disrupt local ecosystems and pose health risks to nearby communities. Cut and fill mining produces less surface disturbance and allows for the backfilling of mined-out areas, reducing subsidence and environmental degradation. Efficient waste management and water control in cut and fill mining mitigate contamination, making it a more environmentally sustainable option compared to drill and blast methods.

Cost Implications and Efficiency

Drill and blast mining generally incurs higher upfront costs due to explosives and specialized drilling equipment but offers faster cycle times and higher throughput in hard rock environments. Cut and fill mining, while more labor-intensive and expensive per ton extracted, provides greater safety and ore recovery in irregular or weak ground conditions. Efficiency in drill and blast is evident in large-scale ore extraction, whereas cut and fill excels in precision and adaptability, impacting overall operational cost structures.

Safety and Risk Management

Drill and blast mining involves controlled explosions to fragment rock, posing significant risks such as fly-rock, vibration, and dust, necessitating stringent safety protocols and blast monitoring systems. Cut and fill mining offers enhanced stability by excavating horizontal slices and backfilling voids, reducing ground control hazards and minimizing exposure to rock falls. Effective risk management in drill and blast requires precise blast design and evacuation procedures, while cut and fill emphasizes continuous ground support and careful material handling to ensure worker safety.

Case Studies: Real-World Applications

Case studies in mining reveal that drill and blast methods excel in large-scale, hard rock environments, such as the Bingham Canyon Mine, enabling efficient fragmentation and high production rates. Cut and fill mining is preferred in irregular or weak ore bodies, with the Hollinger Mine demonstrating improved ground control and ore recovery in complex underground settings. These real-world applications highlight the importance of selecting mining techniques based on geological conditions and operational objectives.

Choosing the Optimal Mining Method

Selecting the optimal mining method hinges on orebody geometry, ground conditions, and economic factors, with drill and blast suited for large, hard rock deposits requiring rapid excavation. Cut and fill mining excels in irregular, steeply dipping orebodies, offering precise ore extraction and enhanced ground support, minimizing dilution. Evaluations of recovery rates, operational costs, and safety protocols are crucial to determine the most effective approach for maximizing resource extraction.

Related Important Terms

Precise Electronic Detonation (PED)

Precise Electronic Detonation (PED) enhances drill and blast mining by improving blast accuracy, reducing vibration, and minimizing rock damage, resulting in more controlled fragmentation and increased operational safety. Cut and fill mining benefits less from PED due to its emphasis on selective ore extraction and ground support rather than extensive blasting optimization.

Vibration Control Blasting

Drill and blast techniques in mining generate vibrations that require precise control measures to minimize impact on surrounding structures, using controlled blasting patterns and timing to reduce peak particle velocity. Cut and fill mining offers better vibration control by allowing incremental excavation and backfilling, which stabilizes the rock mass and limits blast-induced seismic effects.

Emulsion Explosives Optimization

Emulsion explosives optimization in drill and blast operations enhances fragmentation efficiency, reduces vibration, and improves overall ore recovery compared to cut and fill mining, where controlled blasting is less intensive. Employing tailored emulsion formulations maximizes energy utilization, decreases explosive consumption, and lowers environmental impact in open-pit and underground mining contexts.

Real-time Fragmentation Analysis

Real-time fragmentation analysis in drill and blast mining improves fragmentation prediction accuracy, enabling optimized blast designs and reduced secondary breakage costs. In contrast, cut and fill mining relies less on blasting but benefits from real-time monitoring of excavation conditions and material properties to enhance ore recovery and minimize dilution.

Slot Raise Blasting Technique

Slot raise blasting technique in drill and blast mining enhances controlled fragmentation and efficient muck flow by creating precise initial voids for raise development; compared to cut and fill mining, this method reduces dilution and maximizes ore recovery in underground operations. The strategically placed blast holes and optimized explosive charges in slot raise blasting improve ventilation and access while minimizing ground vibrations and improving overall production rates.

Rapid Advance Drilling Rigs

Rapid advance drilling rigs enhance efficiency in drill and blast mining by enabling faster hole drilling and precise blast patterns, reducing cycle times compared to cut and fill mining methods. Their advanced automation and high penetration rates optimize ore extraction while minimizing operational costs in complex underground environments.

Automated Stope Mapping

Automated stope mapping enhances precision in drill and blast mining by enabling real-time data collection and analysis for improved blast design and ore recovery. In cut and fill mining, automated mapping optimizes ore extraction and backfill placement, ensuring safety and reducing waste through accurate spatial monitoring.

Paste Backfill Geotechnical Monitoring

Paste backfill enhances ground stability and reduces surface subsidence in cut and fill mining, supported by geotechnical monitoring systems that track stress and strain in real-time. In contrast, drill and blast methods rely less on paste backfill but require intensive geotechnical monitoring to manage blast-induced vibrations and rock fragmentation for optimized ore extraction.

Digital Drill Pattern Design

Digital drill pattern design enhances precision and efficiency in drill and blast mining by optimizing blast sequences and fragmentation control through advanced software and data analytics. In cut and fill mining, integrating digital models improves excavation accuracy and ore recovery by enabling real-time adjustments to drilling parameters and fill placement strategies.

Sequence-controlled Cut-and-Fill Stoping

Sequence-controlled Cut-and-Fill Stoping enhances ore extraction by systematically filling mined-out voids with waste material, ensuring ground stability and precise ore recovery compared to the larger displacement in Drill and Blast methods. This approach minimizes dilution and increases safety in irregular ore bodies, optimizing overall mining efficiency and resource utilization.

Drill and blast vs Cut and fill mining Infographic

industrydif.com

industrydif.com