Shaft mining involves extracting minerals through vertical tunnels dug into the Earth's crust, primarily targeting valuable resources like coal, metals, and gems found deep underground. Space mining aims to harvest materials from asteroids, the Moon, or other celestial bodies, offering access to rare elements and reducing the environmental impact of terrestrial mining. Advances in robotics and space technology make space mining a promising frontier for securing resources critical to future industries and sustainability.

Table of Comparison

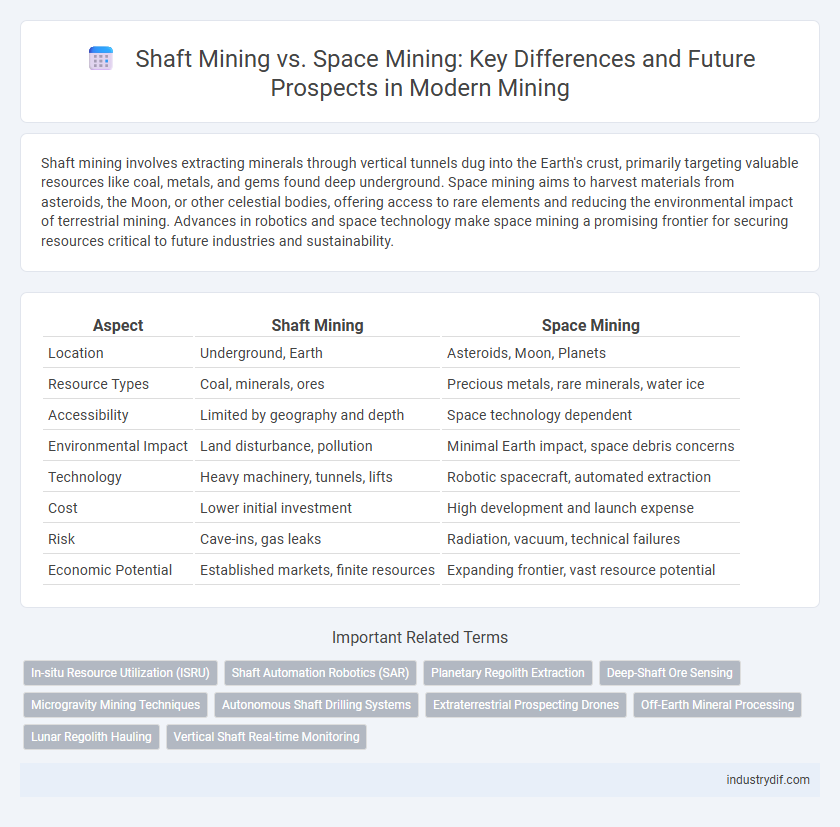

| Aspect | Shaft Mining | Space Mining |

|---|---|---|

| Location | Underground, Earth | Asteroids, Moon, Planets |

| Resource Types | Coal, minerals, ores | Precious metals, rare minerals, water ice |

| Accessibility | Limited by geography and depth | Space technology dependent |

| Environmental Impact | Land disturbance, pollution | Minimal Earth impact, space debris concerns |

| Technology | Heavy machinery, tunnels, lifts | Robotic spacecraft, automated extraction |

| Cost | Lower initial investment | High development and launch expense |

| Risk | Cave-ins, gas leaks | Radiation, vacuum, technical failures |

| Economic Potential | Established markets, finite resources | Expanding frontier, vast resource potential |

Overview of Shaft Mining and Space Mining

Shaft mining involves the vertical excavation of deep tunnels to access underground mineral deposits, commonly used for coal, gold, and other valuable ores on Earth. Space mining targets the extraction of resources from asteroids, the Moon, or other celestial bodies, aiming to obtain rare metals like platinum and water ice for in-situ resource utilization. Both methods require advanced technology, but shaft mining is well-established with extensive infrastructure, whereas space mining is an emerging field with high potential for supporting space exploration and Earth's resource demand.

Key Differences Between Shaft Mining and Space Mining

Shaft mining involves extracting minerals from deep underground through vertical tunnels, relying heavily on extensive infrastructure and human labor, whereas space mining targets asteroids or celestial bodies to retrieve rare elements using robotic technology and remote operations. Key differences include the environment--Earth's gravity and geological constraints versus microgravity and vacuum conditions in space--as well as resource availability, with space mining offering access to precious metals like platinum-group elements not readily accessible on Earth. Furthermore, shaft mining presents significant safety risks and environmental impacts, while space mining poses technical and financial challenges related to transportation and extraction in extraterrestrial settings.

Technological Innovations in Shaft and Space Mining

Shaft mining has advanced through innovations such as automated drilling systems, real-time geological data integration, and enhanced ventilation technologies that improve safety and resource extraction efficiency underground. Space mining leverages cutting-edge robotics, autonomous spacecraft, and in-situ resource utilization (ISRU) technologies to extract materials from asteroids and lunar surfaces with minimal human intervention. The convergence of AI-driven systems and advanced materials processing is driving unprecedented progress in both terrestrial shaft mining and extraterrestrial resource harvesting operations.

Environmental Impacts: Earth vs. Space Mining

Shaft mining on Earth generates significant environmental impacts, including habitat destruction, soil erosion, and contamination from heavy metals and chemicals. Space mining offers a potential reduction in terrestrial ecological damage by extracting resources from asteroids or lunar surfaces, minimizing Earth's land disturbance and pollution. However, the long-term environmental effects of space mining remain uncertain, necessitating further research on space debris and orbital ecosystem preservation.

Cost Analysis: Traditional vs. Extraterrestrial Mining

Shaft mining on Earth involves significant expenses related to labor, safety measures, and environmental impact mitigation, typically costing millions per meter of depth drilled. Space mining, though currently in the prototype phase, promises lower ongoing operational costs by eliminating terrestrial overheads but faces high initial investment for spacecraft development, launch, and remote extraction technology. Cost analysis reveals that while shaft mining exploits known resources with established infrastructure, space mining targets high-value minerals in asteroids, potentially offsetting upfront costs through access to rare materials unavailable on Earth.

Resource Extraction Methods in Shaft and Space Mining

Shaft mining involves vertical tunnels to access underground minerals, using drilling, blasting, and hoisting techniques to extract ores from deep earth deposits. Space mining utilizes robotic spacecraft and autonomous landers to harvest resources from asteroids, moons, or planetary surfaces, often employing laser ablation or mechanical excavation methods. Both methods prioritize efficient resource retrieval but differ significantly in technology, environment, and operational challenges.

Safety Challenges in Shaft Mining and Space Mining

Shaft mining faces significant safety challenges including risks of cave-ins, exposure to hazardous gases, and limited emergency evacuation routes due to deep underground environments. Space mining introduces unique safety concerns such as radiation exposure, microgravity effects on human health, and the potential for equipment failure in remote, harsh extraterrestrial conditions. Both mining methods require stringent safety protocols, but space mining demands advanced life support systems and resilience to cosmic hazards beyond those encountered in traditional shaft mining.

Legal and Regulatory Frameworks

Shaft mining operates under established national and international mining laws that regulate land use, worker safety, and environmental impact within territorial boundaries. Space mining faces evolving legal challenges due to the Outer Space Treaty of 1967, which prohibits national appropriation, creating ambiguity over ownership rights of extracted extraterrestrial resources. Regulatory frameworks for space mining are still developing, involving international cooperation to balance resource extraction with peaceful space exploration and environmental protection.

Future Prospects of Shaft Mining and Space Mining

Shaft mining continues to benefit from advanced automation and improved safety technologies, making it more efficient for extracting deep-earth minerals with minimal environmental impact. Space mining offers unprecedented access to rare resources such as platinum-group metals and water ice on asteroids and the Moon, potentially revolutionizing supply chains for high-tech and energy industries. Future prospects hinge on integrating AI-driven robotics in shaft mining and developing cost-effective space transport, which could enable sustainable resource extraction both underground and extraterrestrially.

Economic Opportunities and Market Potential

Shaft mining offers established economic opportunities with proven market demand for minerals like coal, gold, and copper, benefiting from existing infrastructure and workforce expertise. Space mining presents vast market potential by targeting rare extraterrestrial resources such as platinum-group metals and water ice, which can support space exploration and new industries. Investment in space mining technology could revolutionize supply chains, but high initial costs and technological challenges currently limit its immediate economic viability compared to traditional shaft mining.

Related Important Terms

In-situ Resource Utilization (ISRU)

Shaft mining enables direct extraction of minerals through vertical tunnels, primarily used on Earth where extensive infrastructure supports in-situ resource utilization (ISRU) for processing ores onsite. Space mining leverages ISRU by harvesting extraterrestrial materials from asteroids or lunar surfaces, minimizing payload mass from Earth and enabling sustainable space exploration by converting local resources into fuel, building materials, and life support essentials.

Shaft Automation Robotics (SAR)

Shaft Automation Robotics (SAR) in traditional shaft mining enhances operational efficiency by automating deep underground drilling, material handling, and safety monitoring, significantly reducing human risk and operational costs. In contrast, space mining leverages autonomous SAR systems to extract valuable extraterrestrial resources in harsh environments, relying on advanced robotics for remote operation and resource processing beyond Earth.

Planetary Regolith Extraction

Shaft mining involves extracting minerals from deep underground shafts on Earth, whereas space mining targets planetary regolith, the loose layer of dust and soil covering celestial bodies like the Moon and asteroids. Planetary regolith extraction utilizes specialized techniques such as robotic scooping and in-situ resource utilization to harvest resources like water ice, rare metals, and volatiles essential for off-Earth construction and fuel production.

Deep-Shaft Ore Sensing

Deep-shaft ore sensing in traditional shaft mining employs advanced geophysical techniques such as ground-penetrating radar and seismic tomography to accurately map ore bodies deep underground, enhancing extraction efficiency and safety. In contrast, space mining relies on remote sensing technologies and spectral analysis to identify valuable minerals in asteroids and celestial bodies, but deep subsurface sensing remains a challenge due to limited penetration capabilities in extraterrestrial environments.

Microgravity Mining Techniques

Microgravity mining techniques in space mining leverage the reduced gravitational forces on asteroids or celestial bodies, enabling more efficient extraction of minerals with less energy consumption compared to traditional shaft mining on Earth. These innovative methods utilize robotic drilling and regolith processing in microgravity environments, optimizing resource yield and minimizing environmental impact.

Autonomous Shaft Drilling Systems

Autonomous Shaft Drilling Systems significantly enhance efficiency and safety in traditional shaft mining by automating excavation processes and reducing human intervention in hazardous underground conditions. In contrast, space mining leverages robotic and autonomous technologies to extract valuable minerals from asteroids and celestial bodies, addressing the limitations of terrestrial resource depletion while pushing the frontier of mining innovation.

Extraterrestrial Prospecting Drones

Extraterrestrial prospecting drones revolutionize space mining by enabling precise mineral detection and extraction in asteroid shafts, surpassing traditional underground shaft mining limitations. These autonomous drones leverage advanced sensors and AI analytics to efficiently identify high-value ore deposits on celestial bodies, minimizing human risk and operational costs.

Off-Earth Mineral Processing

Shaft mining, traditionally used for deep Earth mineral extraction, relies on heavy infrastructure and extensive labor, whereas space mining targets asteroids and lunar surfaces to access rare minerals with minimal terrestrial environmental impact. Off-Earth mineral processing involves innovative techniques such as microgravity separation and in-situ resource utilization (ISRU), enabling efficient extraction and refinement of metals like platinum and rare earth elements beyond Earth's atmosphere.

Lunar Regolith Hauling

Shaft mining involves extracting minerals through deep vertical tunnels, whereas space mining of lunar regolith focuses on harvesting surface and near-surface materials on the Moon using robotic hauling systems. Lunar regolith hauling requires specialized equipment capable of operating in low gravity and extreme temperature conditions to efficiently transport soil for in-situ resource utilization and construction.

Vertical Shaft Real-time Monitoring

Vertical shaft real-time monitoring in mining deploys advanced sensor networks and IoT technology to enhance safety, increase operational efficiency, and enable predictive maintenance in deep underground environments. In contrast, space mining relies on remote sensing and automated systems to monitor resource extraction, where real-time data transmission faces latency challenges due to vast distances and limited communication infrastructure.

Shaft mining vs Space mining Infographic

industrydif.com

industrydif.com