Coal mining involves the physical extraction of coal deposits from the earth through surface or underground methods, providing a direct source of solid fossil fuel. Coal seam gas extraction targets methane gas trapped within coal seams, utilizing drilling techniques to release and capture this cleaner-burning energy source. Both methods impact the environment differently, with coal mining causing significant land disturbance and coal seam gas extraction raising concerns about groundwater contamination.

Table of Comparison

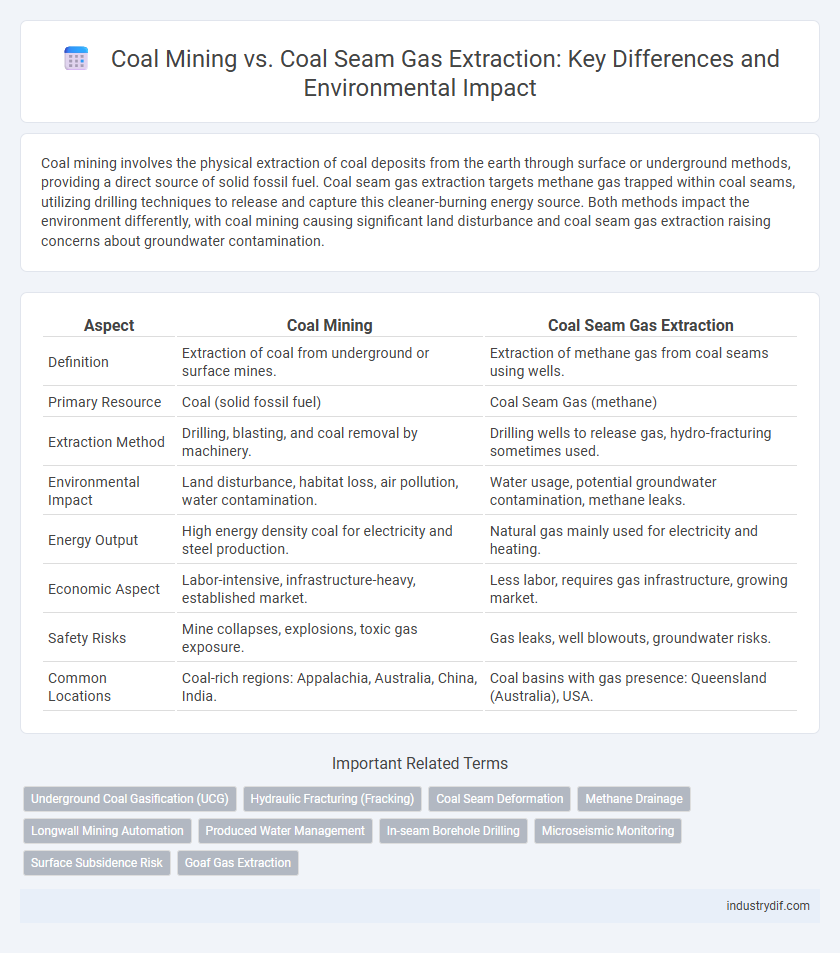

| Aspect | Coal Mining | Coal Seam Gas Extraction |

|---|---|---|

| Definition | Extraction of coal from underground or surface mines. | Extraction of methane gas from coal seams using wells. |

| Primary Resource | Coal (solid fossil fuel) | Coal Seam Gas (methane) |

| Extraction Method | Drilling, blasting, and coal removal by machinery. | Drilling wells to release gas, hydro-fracturing sometimes used. |

| Environmental Impact | Land disturbance, habitat loss, air pollution, water contamination. | Water usage, potential groundwater contamination, methane leaks. |

| Energy Output | High energy density coal for electricity and steel production. | Natural gas mainly used for electricity and heating. |

| Economic Aspect | Labor-intensive, infrastructure-heavy, established market. | Less labor, requires gas infrastructure, growing market. |

| Safety Risks | Mine collapses, explosions, toxic gas exposure. | Gas leaks, well blowouts, groundwater risks. |

| Common Locations | Coal-rich regions: Appalachia, Australia, China, India. | Coal basins with gas presence: Queensland (Australia), USA. |

Overview of Coal Mining and Coal Seam Gas Extraction

Coal mining involves extracting coal from underground or surface mines primarily for energy production and industrial use, while coal seam gas extraction targets methane trapped within coal seams as an alternative energy source. The mining process includes exploration, drilling, and coal handling, whereas coal seam gas extraction employs horizontal drilling and hydraulic fracturing to release gas. Both methods impact the environment and require regulatory management to balance energy demands with ecological preservation.

Geological Differences Between Coal Seams and Gas Reservoirs

Coal seams consist mainly of solid carbonaceous material formed from ancient plant debris undergoing pressure and heat over millions of years, creating dense, stratified layers within sedimentary basins. Gas reservoirs associated with coal seams, known as coal seam gas (CSG) or coalbed methane, are trapped within the porous coal matrix and fractures, relying on natural fractures and cleats for gas storage and flow. Unlike conventional natural gas reservoirs found in sandstone or limestone formations, coal seam gas extraction targets the adsorbed methane within coal, which requires understanding the unique geological properties such as permeability, coal rank, and gas content for efficient recovery.

Extraction Methods: Mining vs Gas Drilling

Coal mining involves physically extracting coal seams through underground or surface mining techniques, utilizing methods such as longwall mining and room-and-pillar mining to access solid mineral deposits. In contrast, coal seam gas extraction requires drilling wells into coal seams to release methane gas trapped within, employing hydraulic fracturing or dewatering processes to increase gas flow. While coal mining disrupts large surface areas and requires significant excavation, coal seam gas extraction has a smaller physical footprint but involves complex gas recovery technologies.

Environmental Impacts of Coal Mining

Coal mining significantly impacts the environment through habitat destruction, soil erosion, and water pollution caused by runoff containing heavy metals and toxic chemicals. The release of methane, a potent greenhouse gas, during coal extraction contributes to global warming and air quality degradation. Land subsidence and acid mine drainage further threaten ecosystems and groundwater resources surrounding coal mining sites.

Environmental Impacts of Coal Seam Gas Extraction

Coal seam gas extraction significantly affects ecosystems by causing groundwater contamination and altering water tables, which threatens biodiversity and agricultural productivity. Methane emissions from coal seam gas operations contribute to greenhouse gases, intensifying climate change concerns in mining regions. Land disturbance from infrastructure development further disrupts habitats and soil stability, necessitating stringent environmental management practices.

Water Usage and Management in Both Industries

Coal mining typically requires significant water for dust suppression, coal washing, and slurry transport, often stressing local water resources and necessitating extensive management strategies to prevent contamination. Coal seam gas extraction involves extracting methane by pumping large volumes of water from coal seams, which can lead to groundwater depletion and necessitates careful treatment and disposal of produced water to avoid ecological harm. Both industries face challenges in sustainable water usage, requiring advanced monitoring and recycling techniques to mitigate environmental impacts and comply with regulatory frameworks.

Economic Benefits and Employment Opportunities

Coal mining provides substantial economic benefits through the direct extraction of coal, supporting millions of jobs worldwide in mining, transportation, and processing sectors. Coal seam gas extraction offers significant opportunities for economic growth by utilizing underground natural gas resources, with job creation concentrated in drilling, production, and infrastructure development. Both industries contribute to regional economies, but coal seam gas extraction tends to generate more sustainable employment opportunities due to its lower environmental impact and expanding global demand.

Health and Safety Risks to Workers and Communities

Coal mining exposes workers to respiratory hazards such as coal dust, leading to pneumoconiosis and chronic obstructive pulmonary disease, while coal seam gas extraction risks include chemical exposure and groundwater contamination affecting community health. Both industries carry risks of accidents, but coal seam gas extraction presents additional dangers from high-pressure equipment and potential gas leaks. Effective safety protocols and continuous monitoring are critical to mitigating health risks for workers and nearby populations in both coal mining and coal seam gas operations.

Land Rehabilitation and Post-Extraction Management

Coal mining often results in significant landscape disruption, requiring extensive land rehabilitation to restore soil quality and native vegetation. Coal seam gas extraction typically involves smaller land footprints, but managing groundwater contamination and surface disturbance is crucial for effective post-extraction land restoration. Both industries implement tailored rehabilitation strategies, emphasizing ecosystem recovery and sustainable land use post-extraction.

Regulatory Frameworks and Industry Standards

Coal mining and coal seam gas (CSG) extraction operate under distinct regulatory frameworks that address their specific environmental and safety risks. Coal mining regulations emphasize land rehabilitation, dust control, and worker safety due to extensive surface disruption and coal dust hazards. In contrast, CSG extraction standards prioritize groundwater protection, methane emissions management, and hydraulic fracturing oversight to mitigate impacts on water resources and greenhouse gas emissions.

Related Important Terms

Underground Coal Gasification (UCG)

Underground Coal Gasification (UCG) offers a transformative approach to coal mining by converting unmineable coal seams into syngas through in-situ combustion, enabling cleaner extraction compared to traditional coal mining and coal seam gas extraction. UCG minimizes surface disruption and reduces methane emissions, providing an efficient alternative to conventional underground mining and hydraulic fracturing used in coal seam gas recovery.

Hydraulic Fracturing (Fracking)

Hydraulic fracturing in coal seam gas extraction involves injecting high-pressure fluid to create fractures in coal beds, releasing methane gas with less surface disruption compared to traditional coal mining, which relies on physically excavating coal deposits. This technique enhances gas recovery from deep seams but raises environmental concerns around groundwater contamination and induced seismicity.

Coal Seam Deformation

Coal seam gas extraction induces significant coal seam deformation due to the reduction in pore pressure and changes in effective stress, often leading to subsidence and fractures within the coal matrix. In contrast, traditional coal mining causes more abrupt and extensive deformation through mechanical excavation, resulting in larger-scale ground movement and potential hazard zones around the mined areas.

Methane Drainage

Methane drainage in coal mining involves extracting methane directly from coal seams to reduce explosion risks and harness energy, whereas coal seam gas extraction targets methane by drilling into deeper coal layers for commercial gas production. Effective methane drainage enhances mine safety and increases the efficiency of coal seam gas recovery, minimizing greenhouse gas emissions from mining operations.

Longwall Mining Automation

Longwall mining automation in coal extraction leverages advanced robotics and sensors to improve safety and efficiency by precisely controlling shearer operation along the seam, reducing human exposure to hazardous environments. In contrast to coal seam gas extraction, which primarily involves drilling and hydraulic fracturing techniques to release methane, longwall automation directly enhances underground coal productivity through continuous, mechanized cutting and roof support systems.

Produced Water Management

Produced water management in coal mining primarily involves handling groundwater and process water contaminated with suspended solids and hydrocarbons, requiring treatment methods such as sedimentation, filtration, and chemical dosing. In coal seam gas extraction, produced water, often saline and containing naturally occurring substances like salts and heavy metals, demands advanced treatment technologies including membrane filtration, reverse osmosis, and reinjection to mitigate environmental impacts and comply with regulatory standards.

In-seam Borehole Drilling

In-seam borehole drilling in coal mining involves extracting coal directly by creating boreholes within coal seams, maximizing resource recovery and minimizing surface disturbance. In contrast, coal seam gas extraction uses similar boreholes to release methane gas trapped in coal seams, providing an alternative energy source while requiring careful management of gas pressure and environmental safety.

Microseismic Monitoring

Microseismic monitoring plays a critical role in both coal mining and coal seam gas extraction by providing real-time data on fracture propagation and seismic events, enhancing safety and operational efficiency. In coal seam gas extraction, microseismic techniques are essential for mapping fracture networks and optimizing gas recovery, while in coal mining, they help detect rock bursts and ground instability.

Surface Subsidence Risk

Coal mining often causes significant surface subsidence due to the removal of large underground coal seams, leading to ground instability and damage to infrastructure. In contrast, coal seam gas extraction typically results in lower subsidence risk as it involves gas drainage with minimal disruption to the overlying strata, preserving surface integrity.

Goaf Gas Extraction

Goaf gas extraction in coal mining targets methane trapped within collapsed mine voids, reducing greenhouse gas emissions and improving mine safety by preventing gas explosions. Unlike coal seam gas extraction that extracts methane from unmined coal seams, goaf gas extraction mainly recovers gas from previously mined areas, optimizing resource utilization and minimizing environmental impact.

Coal Mining vs Coal Seam Gas Extraction Infographic

industrydif.com

industrydif.com