Room and pillar mining involves excavating mineral deposits by creating a series of rooms supported by pillars of ore, providing stability with minimal surface subsidence. Block caving is an underground mining method where a large section of ore is undercut, causing it to collapse under its own weight, allowing for the efficient extraction of low-grade, massive ore bodies. Room and pillar suits flat-lying deposits with moderate depth, while block caving excels in large, deep deposits where economies of scale reduce operational costs.

Table of Comparison

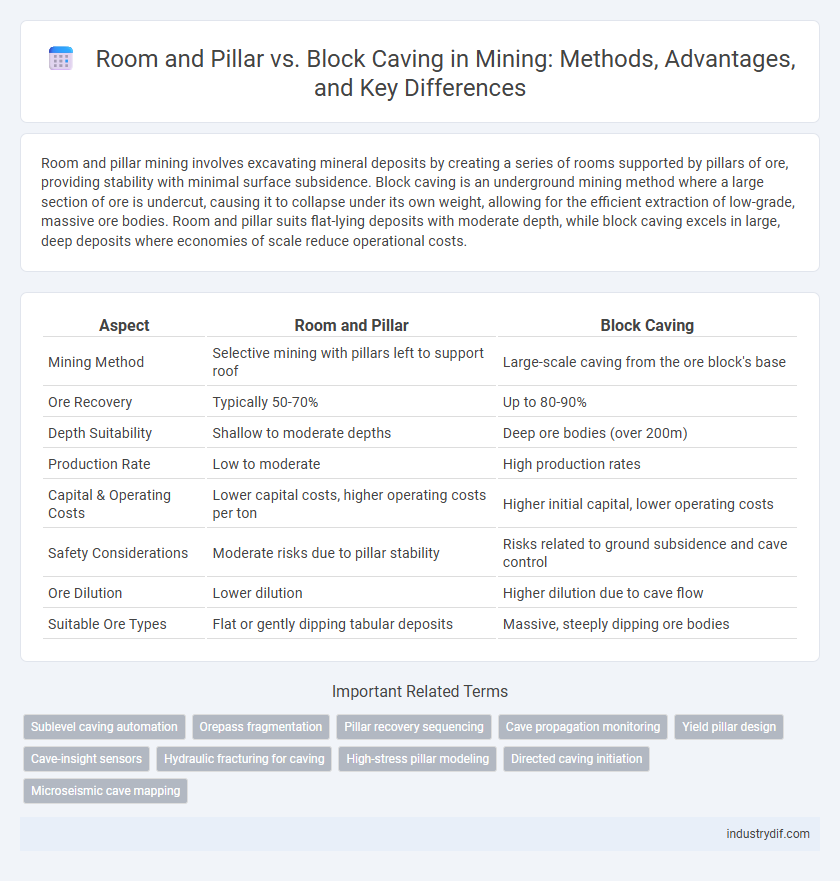

| Aspect | Room and Pillar | Block Caving |

|---|---|---|

| Mining Method | Selective mining with pillars left to support roof | Large-scale caving from the ore block's base |

| Ore Recovery | Typically 50-70% | Up to 80-90% |

| Depth Suitability | Shallow to moderate depths | Deep ore bodies (over 200m) |

| Production Rate | Low to moderate | High production rates |

| Capital & Operating Costs | Lower capital costs, higher operating costs per ton | Higher initial capital, lower operating costs |

| Safety Considerations | Moderate risks due to pillar stability | Risks related to ground subsidence and cave control |

| Ore Dilution | Lower dilution | Higher dilution due to cave flow |

| Suitable Ore Types | Flat or gently dipping tabular deposits | Massive, steeply dipping ore bodies |

Overview of Room and Pillar Mining

Room and pillar mining involves extracting mineral deposits by creating a series of rooms while leaving pillars of ore or waste to support the roof, ensuring safety and stability. This method is commonly used in flat-lying ore bodies such as coal seams and potash deposits, allowing for controlled extraction with minimal surface subsidence. Compared to block caving, room and pillar mining offers more selective ore recovery but typically results in lower extraction ratios and requires careful pillar design to prevent collapse.

Fundamentals of Block Caving

Block caving is an underground mining method where a large ore body is undercut, causing it to collapse under its own weight, enabling gravity to assist in ore extraction. This technique differs from room and pillar mining, which involves leaving pillars of ore to support the roof while extracting ore from the surrounding rooms. Block caving is highly cost-effective for mining large, low-grade ore bodies with significant vertical extent, providing high production rates and improved safety due to controlled cave propagation.

Historical Development of Underground Mining Methods

Room and pillar mining, one of the earliest underground methods dating back thousands of years, was widely used due to its simplicity and safety in stable rock conditions. Block caving emerged in the mid-20th century as an innovative bulk mining technique designed for massive, low-grade ore bodies, significantly improving extraction efficiency and reducing costs. The historical evolution from room and pillar to block caving reflects advancements in engineering technology and economic demands for large-scale mineral production.

Geological Conditions Favoring Room and Pillar

Room and pillar mining is favored in geological conditions with flat-lying, moderately thick, and competent ore bodies that maintain stability without excessive support. This method is ideal for shallow deposits with uniform rock strength where pillars can effectively support the overlying strata. In contrast, block caving requires massive, highly fractured orebodies that allow controlled collapse, making it unsuitable for the stable conditions preferred by room and pillar mining.

Geological Requirements for Block Caving

Block caving requires massive, low-fracture, and competent rock masses capable of extensive caving without premature collapse, making it suitable for ore bodies with significant vertical extent and uniform geology. In contrast, room and pillar mining can accommodate more variable geological conditions but demands stable pillar formations to support the overlying strata. The success of block caving heavily depends on favorable geotechnical properties such as minimal faulting, strong rock cohesion, and predictable fragmentation behavior.

Equipment Used in Room and Pillar vs Block Caving

Room and pillar mining employs continuous miners and shuttle cars to extract and transport ore, optimizing flexibility and safety in flat-lying deposits. Block caving utilizes massive load-haul-dump (LHD) machines and conveyors designed for large-scale ore extraction from collapsed blocks, emphasizing high production rates. The choice of equipment is influenced by geological conditions and operational scale, with room and pillar favoring mechanized systems for intact roofs and block caving requiring robust machinery for subsidence control.

Ore Recovery and Extraction Efficiency

Room and pillar mining typically achieves ore recovery rates between 50% and 70%, as pillars are left in place to support the roof, limiting full extraction. Block caving offers higher extraction efficiency, often exceeding 80%, by allowing large volumes of ore to collapse and be collected continuously from drawpoints. The choice between methods depends on ore body geometry and desired recovery rates, with block caving favored for maximizing ore recovery in massive, lower-grade deposits.

Safety and Environmental Considerations

Room and pillar mining offers enhanced safety due to its controlled excavation method, minimizing ground collapse risks by leaving pillars to support the roof. In contrast, block caving, while more cost-efficient for large-scale ore extraction, poses higher safety risks related to subsidence and ground instability. Environmentally, room and pillar mining generates less surface disruption, whereas block caving can lead to significant land subsidence and increased surface impact.

Economic Comparison: CapEx and OpEx

Room and pillar mining generally involves lower capital expenditures (CapEx) due to simpler infrastructure and equipment requirements compared to block caving, which demands significant upfront investment in underground development and advanced machinery. Operational expenditures (OpEx) in room and pillar methods tend to be higher over time because of continuous roof support, manual labor, and selective extraction processes, whereas block caving benefits from economies of scale with lower per-ton operating costs after initial development. Evaluating long-term economic viability, block caving often yields superior cost efficiency in large, low-grade ore bodies despite its higher CapEx, while room and pillar is more cost-effective for smaller, high-grade deposits with complex geology.

Application Examples in the Mining Industry

Room and pillar mining is widely used in flat-lying coal seams and industrial mineral deposits, exemplified by its application in the Illinois coal basin and potash mines in Saskatchewan. Block caving is preferred for large, low-grade, deep ore bodies, as demonstrated by its use in the Grasberg mine in Indonesia and the El Teniente copper mine in Chile. Each method optimizes resource recovery and operational efficiency based on ore body geometry and economic factors.

Related Important Terms

Sublevel caving automation

Sublevel caving automation significantly enhances operational efficiency by integrating advanced sensors and autonomous drilling machinery to optimize ore extraction in both room and pillar and block caving methods. While room and pillar mining benefits from precise automated support systems for maintaining pillar stability, block caving leverages automation for controlled fragmentation and material flow, increasing yield and reducing manual labor risks.

Orepass fragmentation

Room and pillar mining maintains ore integrity with minimal fragmentation, facilitating controlled ore passes, whereas block caving induces extensive fragmentation, enhancing orepass flow but requiring robust handling systems to manage the high rock mass movement. Orepass fragmentation in block caving significantly improves material flow efficiency, reducing blockages compared to the more consolidated ore in room and pillar operations.

Pillar recovery sequencing

Pillar recovery sequencing in room and pillar mining involves strategic extraction of ore pillars to maximize resource recovery while maintaining underground stability, often employing systematic retreat patterns to minimize ground control risks. In contrast, block caving uses controlled collapse and ore fragmentation beneath a block, where sequencing focuses on cave propagation and draw control to optimize ore flow and minimize dilution.

Cave propagation monitoring

Room and pillar mining enables controlled cave propagation monitoring by maintaining stable pillars that prevent sudden collapses, whereas block caving relies on advanced geotechnical instruments and microseismic monitoring to track progressive cave propagation and ensure operational safety. Effective cave propagation monitoring in block caving integrates real-time data analytics and remote sensing technologies for early detection of ground movements and hazard prediction.

Yield pillar design

Yield pillar design in room and pillar mining optimizes ore recovery by allowing controlled pillar failure to improve cube recovery, whereas block caving relies on large-scale caving without distinct pillars, emphasizing the stability of the cave-in zone. Effective yield pillar design balances immediate extraction with long-term ground control, enhancing safety and maximizing ore yield in flat or gently dipping ore bodies.

Cave-insight sensors

Room and pillar mining relies heavily on cave-insight sensors to monitor ground stability and prevent sudden collapses, ensuring worker safety in excavated voids. Block caving utilizes advanced cave-insight sensors for early detection of subsidence and fractures, optimizing cave progression control and minimizing risk during large-scale underground extraction.

Hydraulic fracturing for caving

Room and pillar mining involves creating a network of voids supported by pillars, while block caving uses natural fracturing to collapse ore bodies, enhancing extraction efficiency. Hydraulic fracturing, applied in block caving, increases rock permeability and induces controlled caving by injecting high-pressure fluids, improving ore recovery and reducing ground control risks.

High-stress pillar modeling

High-stress pillar modeling in room and pillar mining involves detailed geomechanical analysis to optimize pillar size and prevent failure under significant overburden pressure. In contrast, block caving relies on controlled fracturing of large ore bodies, where pillar support is minimal, making pillar stress modeling less critical compared to the concentrated load-bearing demands in room and pillar layouts.

Directed caving initiation

Directed caving initiation in room and pillar mining allows precise control over ore extraction by creating stable pillars that support the roof while coordinating controlled collapse, enhancing safety and resource recovery. In contrast, block caving relies on gravity-induced collapse without directed initiation, enabling large-scale ore extraction but with less control over subsidence and cave propagation.

Microseismic cave mapping

Room and pillar mining maintains structural stability by leaving pillars, while block caving involves controlled collapse to extract ore efficiently; microseismic cave mapping is essential in block caving to monitor rock mass behavior and optimize cave propagation. Microseismic data provides real-time insights into fracture development and subsidence patterns, enabling safer and more productive block caving operations compared to the more stable but less efficient room and pillar method.

Room and pillar vs Block caving Infographic

industrydif.com

industrydif.com