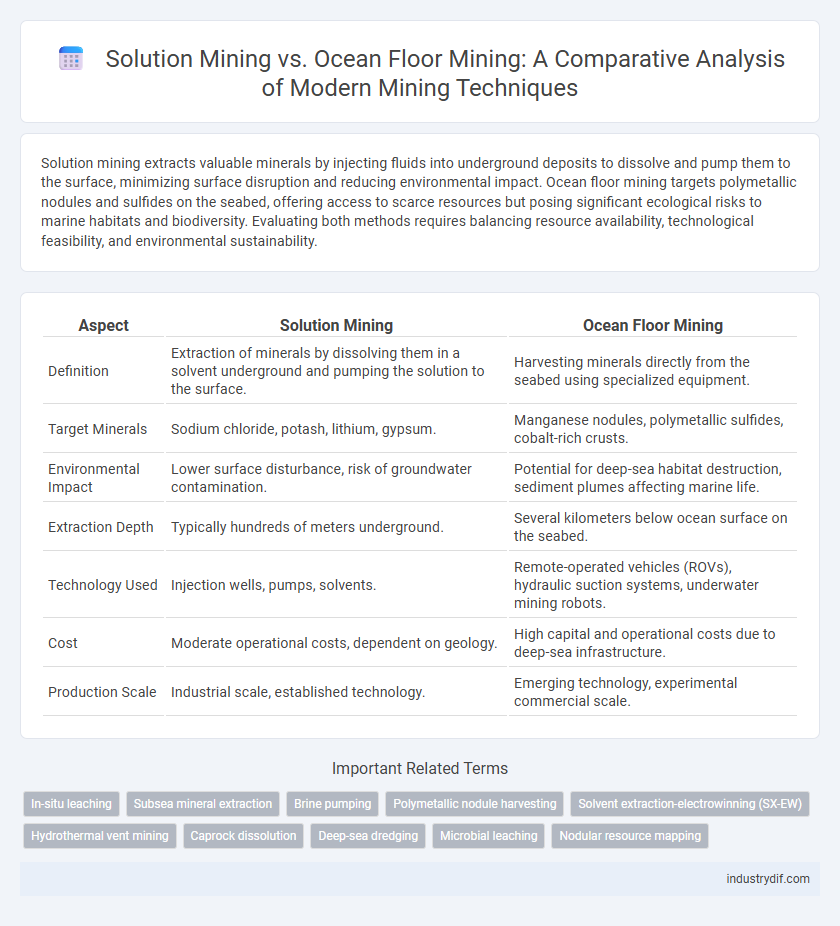

Solution mining extracts valuable minerals by injecting fluids into underground deposits to dissolve and pump them to the surface, minimizing surface disruption and reducing environmental impact. Ocean floor mining targets polymetallic nodules and sulfides on the seabed, offering access to scarce resources but posing significant ecological risks to marine habitats and biodiversity. Evaluating both methods requires balancing resource availability, technological feasibility, and environmental sustainability.

Table of Comparison

| Aspect | Solution Mining | Ocean Floor Mining |

|---|---|---|

| Definition | Extraction of minerals by dissolving them in a solvent underground and pumping the solution to the surface. | Harvesting minerals directly from the seabed using specialized equipment. |

| Target Minerals | Sodium chloride, potash, lithium, gypsum. | Manganese nodules, polymetallic sulfides, cobalt-rich crusts. |

| Environmental Impact | Lower surface disturbance, risk of groundwater contamination. | Potential for deep-sea habitat destruction, sediment plumes affecting marine life. |

| Extraction Depth | Typically hundreds of meters underground. | Several kilometers below ocean surface on the seabed. |

| Technology Used | Injection wells, pumps, solvents. | Remote-operated vehicles (ROVs), hydraulic suction systems, underwater mining robots. |

| Cost | Moderate operational costs, dependent on geology. | High capital and operational costs due to deep-sea infrastructure. |

| Production Scale | Industrial scale, established technology. | Emerging technology, experimental commercial scale. |

Overview of Solution Mining

Solution mining involves extracting valuable minerals by injecting solvents into underground deposits to dissolve resources such as salt, potash, or lithium, which are then pumped to the surface for processing. This method offers targeted extraction with minimal surface disruption and is cost-effective for soluble minerals. Compared to ocean floor mining, solution mining benefits from established technologies and lower environmental risks while relying heavily on precise geological knowledge and groundwater management.

Overview of Ocean Floor Mining

Ocean floor mining involves extracting valuable minerals such as polymetallic nodules, cobalt-rich crusts, and seafloor massive sulfides from the seabed, typically at depths of 1,000 to 6,000 meters. This technique leverages advanced remotely operated vehicles (ROVs) and hydraulic lifts to collect resources with minimal surface disruption, offering access to untapped reserves rich in metals like nickel, copper, and rare earth elements. Ocean floor mining presents a strategic alternative to solution mining by tapping into vast underwater deposits that are otherwise inaccessible through traditional terrestrial or in-situ leaching methods.

Key Processes in Solution Mining

Solution mining involves injecting solvents such as water, acids, or brine into underground mineral deposits to dissolve target minerals, which are then pumped to the surface for extraction. Key processes include leaching, where specific minerals like potash or salt are dissolved in situ, and the recovery of the mineral-rich solution through wells drilled into the deposit. This method contrasts with ocean floor mining, which physically extracts minerals like polymetallic nodules or seafloor massive sulfides directly from the seabed using remote-operated vehicles and specialized equipment.

Key Processes in Ocean Floor Mining

Ocean floor mining involves extracting valuable minerals such as polymetallic nodules, crusts, and hydrothermal vents from the seabed using remotely operated vehicles (ROVs) and specialized seabed mining systems. Key processes include seabed mapping and resource assessment, sediment removal through hydraulic or mechanical collectors, and surface processing to separate minerals from extracted materials. This method contrasts with solution mining, which extracts minerals by injecting fluids into underground deposits, relying heavily on chemical dissolution rather than physical extraction from solid seabed deposits.

Environmental Impacts: Solution Mining vs Ocean Floor Mining

Solution mining minimizes surface disruption by extracting minerals through boreholes, reducing habitat destruction and soil erosion compared to traditional mining methods. Ocean floor mining poses significant risks to marine ecosystems, including biodiversity loss and sediment plumes that harm filter feeders and coral reefs. Both methods require stringent environmental monitoring, but ocean floor mining's deep-sea disturbances create long-lasting impacts on fragile underwater habitats.

Economic Feasibility and Costs

Solution mining offers lower upfront capital expenditure and operational costs compared to ocean floor mining, primarily due to established technology and onshore infrastructure utilization. Ocean floor mining involves significantly higher investment in specialized equipment, exploration, and environmental safeguards, driving economic feasibility challenges. Cost analysis reveals solution mining's advantage in shorter project timelines and reduced extraction complexity, enhancing profitability prospects.

Resource Accessibility and Recovery Rates

Solution mining enables efficient extraction of soluble minerals such as salt and potash by injecting solvents into subterranean deposits, resulting in high recovery rates and minimal surface disruption. Ocean floor mining targets polymetallic nodules and sulfide deposits, offering access to vast, untapped mineral resources on the seabed but faces challenges with lower recovery efficiency due to complex extraction conditions. Resource accessibility in solution mining is typically more predictable and controlled, whereas ocean floor mining requires advanced technology to navigate deep-sea environments and achieve optimal recovery.

Technological Innovations in Mining Methods

Solution mining employs advanced in-situ leaching technology to extract minerals like potash and salt by dissolving them underground and pumping the brine to the surface, minimizing surface disruption. Ocean floor mining utilizes remotely operated vehicles (ROVs) and deep-sea mining equipment designed for high-pressure, low-temperature environments to harvest polymetallic nodules, cobalt crusts, and sulfides from seabed mineral deposits. Both methods incorporate cutting-edge sensor technologies and real-time data analytics to enhance operational efficiency and environmental monitoring during extraction processes.

Regulatory Frameworks and Industry Standards

Solution mining is governed by established regulatory frameworks emphasizing environmental protection and groundwater safety, with strict compliance to EPA regulations and industry standards such as ANSI/ASME codes. Ocean floor mining faces emerging regulatory challenges under international law, including the United Nations Convention on the Law of the Sea (UNCLOS), with limited but evolving standards focused on biodiversity preservation and marine ecosystem impact. Both methods require adherence to monitoring protocols and impact assessments, but ocean floor mining demands more collaborative international governance due to its transboundary nature.

Future Trends in Solution and Ocean Floor Mining

Future trends in solution mining emphasize increased automation and enhanced environmental monitoring systems to boost efficiency and reduce ecological impact. Ocean floor mining is advancing with the development of robotic technologies and deep-sea exploration equipment to access polymetallic nodules and rare earth elements sustainably. Integration of real-time data analytics and AI-driven resource management is expected to optimize extraction processes in both mining methods.

Related Important Terms

In-situ leaching

Solution mining utilizes in-situ leaching techniques to extract valuable minerals dissolved in subterranean water, minimizing surface disruption and reducing environmental footprint compared to ocean floor mining, which involves mechanical extraction of minerals from seabed deposits. In-situ leaching offers a more energy-efficient and cost-effective alternative, especially for uranium and potash, while ocean floor mining targets polymetallic nodules, requiring advanced technology to operate in high-pressure, deep-sea environments.

Subsea mineral extraction

Solution mining leverages injected fluids to dissolve and extract minerals from underground deposits, minimizing surface disruption and enabling selective recovery of resources such as potash and salt. Ocean floor mining targets polymetallic nodules, sulfides, and cobalt-rich crusts on the seabed, utilizing remotely operated vehicles (ROVs) and advanced subsea technology to harvest valuable metals like manganese, nickel, and rare earth elements essential for modern industries.

Brine pumping

Solution mining extracts valuable minerals by injecting water or solvents into underground deposits to dissolve soluble salts and pumping the resulting brine to the surface, offering targeted resource recovery with minimal surface disruption. Ocean floor mining collects polymetallic nodules and sulfides directly from the seabed but faces challenges such as environmental impact and complex brine management due to the extraction of seawater minerals.

Polymetallic nodule harvesting

Polymetallic nodule harvesting via solution mining extracts valuable metals like manganese, nickel, and cobalt by dissolving nodules in situ using chemical leaching, minimizing seabed disturbance compared to ocean floor mining, which physically collects nodules from the sediment surface. This method reduces environmental impact but requires advanced technology to efficiently process metals dissolved in the ocean, presenting challenges in scalability and economic viability.

Solvent extraction-electrowinning (SX-EW)

Solution mining utilizes solvent extraction-electrowinning (SX-EW) to efficiently recover metals like copper by dissolving ores with a solvent and then electro-winning the metal from the leachate, offering lower environmental impact and operational costs compared to ocean floor mining. Ocean floor mining faces challenges such as deep-sea ecology disruption and high extraction costs, whereas SX-EW in solution mining provides a scalable and environmentally preferred method for metal recovery from brines or low-grade ores.

Hydrothermal vent mining

Hydrothermal vent mining exploits mineral-rich deposits formed by superheated, metal-laden fluids emitted from ocean floor vents, offering access to valuable metals like copper, gold, and rare earth elements often concentrated in sulfide chimneys. This method contrasts with solution mining, which extracts soluble minerals by injecting fluids into underground deposits, whereas hydrothermal vent mining uniquely targets biochemically deposited mineral veins in extreme deep-sea environments.

Caprock dissolution

Solution mining involves the selective dissolution of minerals by injecting solvents into subsurface ore deposits, allowing for caprock dissolution that facilitates targeted extraction while minimizing surface disruption. Ocean floor mining, by contrast, poses challenges in caprock dissolution due to high-pressure and low-temperature conditions, making chemical dissolution less efficient and increasing the risk of habitat disturbance.

Deep-sea dredging

Solution mining extracts minerals by injecting solvents into underground deposits, offering precise resource recovery with minimal surface disruption, while ocean floor mining, particularly deep-sea dredging, involves collecting polymetallic nodules and sulfide deposits from the seabed, presenting challenges such as habitat disturbance and deep-water ecosystem impact. Deep-sea dredging equipment uses remotely operated vehicles (ROVs) or autonomous underwater vehicles (AUVs) to harvest minerals at depths exceeding 4,000 meters, making it technologically demanding yet strategically important for accessing critical metals like cobalt, nickel, and manganese.

Microbial leaching

Microbial leaching enhances solution mining by utilizing bacteria to extract metals from ores dissolved in liquids, increasing metal recovery efficiency with minimal environmental impact. Ocean floor mining, while promising vast mineral resources, faces challenges in microbial leaching due to extreme pressure and low temperatures that limit bacterial activity and metal bioavailability.

Nodular resource mapping

Solution mining provides precise nodular resource mapping through in-situ leaching and selective extraction techniques, enabling efficient recovery of minerals from underground deposits. Ocean floor mining relies on advanced sonar and remote sensing technologies to map vast nodular fields, but challenges in resolution and environmental disturbances persist compared to solution mining's targeted approach.

Solution mining vs Ocean floor mining Infographic

industrydif.com

industrydif.com