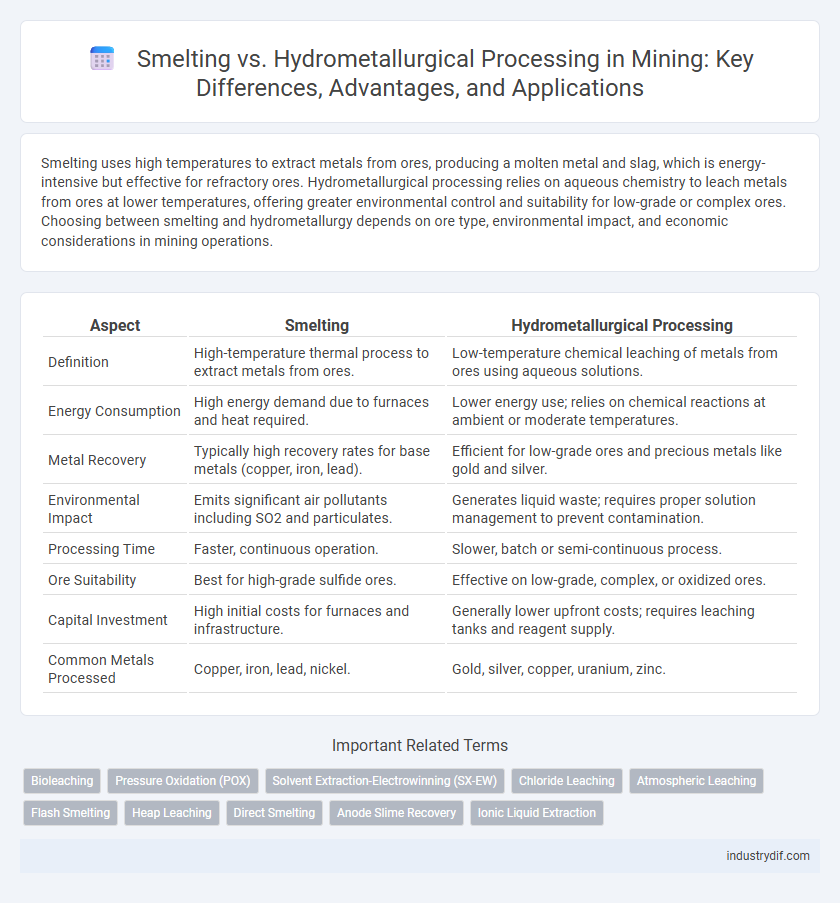

Smelting uses high temperatures to extract metals from ores, producing a molten metal and slag, which is energy-intensive but effective for refractory ores. Hydrometallurgical processing relies on aqueous chemistry to leach metals from ores at lower temperatures, offering greater environmental control and suitability for low-grade or complex ores. Choosing between smelting and hydrometallurgy depends on ore type, environmental impact, and economic considerations in mining operations.

Table of Comparison

| Aspect | Smelting | Hydrometallurgical Processing |

|---|---|---|

| Definition | High-temperature thermal process to extract metals from ores. | Low-temperature chemical leaching of metals from ores using aqueous solutions. |

| Energy Consumption | High energy demand due to furnaces and heat required. | Lower energy use; relies on chemical reactions at ambient or moderate temperatures. |

| Metal Recovery | Typically high recovery rates for base metals (copper, iron, lead). | Efficient for low-grade ores and precious metals like gold and silver. |

| Environmental Impact | Emits significant air pollutants including SO2 and particulates. | Generates liquid waste; requires proper solution management to prevent contamination. |

| Processing Time | Faster, continuous operation. | Slower, batch or semi-continuous process. |

| Ore Suitability | Best for high-grade sulfide ores. | Effective on low-grade, complex, or oxidized ores. |

| Capital Investment | High initial costs for furnaces and infrastructure. | Generally lower upfront costs; requires leaching tanks and reagent supply. |

| Common Metals Processed | Copper, iron, lead, nickel. | Gold, silver, copper, uranium, zinc. |

Introduction to Metal Extraction Methods

Smelting involves extracting metals from their ores through high-temperature melting, which separates valuable metals from impurities by utilizing chemical reduction reactions. Hydrometallurgical processing uses aqueous solutions to leach metals from ores, enabling metal recovery through solvent extraction and electrowinning, often performed at lower temperatures compared to smelting. Both methods are essential in mining, with smelting typically applied to sulfide ores and hydrometallurgy favored for oxide ores and low-grade materials due to energy efficiency and environmental considerations.

Overview of Smelting Technology

Smelting technology involves the extraction of metals from their ores through high-temperature chemical reduction, typically in a blast furnace or electric arc furnace, producing molten metal and slag. This pyrometallurgical process is essential for refining base metals such as copper, nickel, and iron, enabling the removal of impurities and recovery of valuable elements. Key advantages of smelting include high metal recovery rates and the ability to process complex concentrates, though it requires significant energy inputs and generates emissions needing environmental management.

Fundamentals of Hydrometallurgical Processing

Hydrometallurgical processing involves extracting metals from ores by using aqueous chemistry, primarily through leaching, solution concentration, and metal recovery techniques. This method offers advantages over smelting by enabling the treatment of low-grade ores and complex materials at lower temperatures, reducing energy consumption and environmental impact. Key fundamentals include selecting appropriate lixiviants, optimizing reaction kinetics, and ensuring efficient downstream separation processes such as solvent extraction and electrowinning.

Key Differences: Smelting vs Hydrometallurgy

Smelting involves high-temperature melting to extract metals from ores by separating the metal from impurities through chemical reduction, typically requiring significant energy input and producing slag as a byproduct. Hydrometallurgical processing, on the other hand, uses aqueous chemistry to dissolve and selectively recover metals at lower temperatures, employing techniques such as leaching, solvent extraction, and electrowinning, which offer greater environmental control and flexibility with lower emissions. The choice between smelting and hydrometallurgy depends on ore type, metal concentration, energy costs, and environmental regulations, with hydrometallurgy favored for complex or low-grade ores.

Process Steps in Smelting Operations

Smelting operations involve several key process steps, including ore preparation, roasting to remove sulfur and moisture, and high-temperature furnace treatment to extract metal from its ore. Molten metal is separated from slag through settling in a furnace, followed by tapping and refining to improve purity. These steps contrast with hydrometallurgical processing, which relies on chemical leaching of metals in aqueous solutions rather than thermal decomposition.

Hydrometallurgical Techniques and Applications

Hydrometallurgical techniques utilize aqueous chemistry to extract metals from ores, enabling the recovery of valuable metals such as gold, copper, and nickel under lower temperature conditions compared to smelting. Processes like leaching, solvent extraction, and electrowinning enhance metal recovery rates and reduce environmental impact by minimizing emissions and energy consumption. These applications are particularly advantageous for low-grade ores and complex mineral matrices, offering efficient and sustainable metal extraction alternatives.

Environmental Impacts: Smelting vs Hydrometallurgy

Smelting generates significant air pollution through sulfur dioxide and metal emissions, contributing to acid rain and respiratory issues, whereas hydrometallurgical processing produces less airborne pollution but generates large volumes of toxic wastewater requiring extensive treatment. The high energy consumption of smelting processes results in greater greenhouse gas emissions compared to hydrometallurgical methods, which typically operate at lower temperatures and use aqueous solutions. Waste management challenges differ as smelting produces solid slags with heavy metals, while hydrometallurgy leads to contaminated liquid effluents demanding advanced filtration and neutralization techniques.

Energy Consumption and Efficiency Comparison

Smelting typically consumes higher energy due to the need for extreme temperatures to melt ores, often exceeding 1,500degC, while hydrometallurgical processing operates at lower temperatures, significantly reducing energy demand. Hydrometallurgical methods like leaching provide higher metal recovery rates for low-grade ores and complex materials, enhancing overall efficiency compared to smelting. Energy efficiency in hydrometallurgical processing is further improved by integrating processes such as solvent extraction and electrowinning, enabling lower operational costs and reduced environmental impact.

Economic Considerations in Metal Processing

Smelting typically demands higher capital investment and energy costs but allows for the processing of complex ores with high throughput, leading to economies of scale. Hydrometallurgical processing often incurs lower upfront costs and operates at lower temperatures, reducing energy expenditure, which enhances profitability for low-grade or precious metal ores. Economic considerations revolve around ore grade, metal recovery rates, environmental regulations, and market metal prices, influencing the choice between smelting and hydrometallurgy.

Future Trends in Metallurgical Processing

Future trends in metallurgical processing emphasize the integration of smelting and hydrometallurgical techniques to enhance metal recovery efficiency and reduce environmental impact. Innovations in low-temperature smelting technologies and advanced solvent extraction methods are driving sustainable practices in the industry. Increased automation and real-time monitoring optimize process control, contributing to improved resource utilization and lower carbon emissions in metal extraction.

Related Important Terms

Bioleaching

Bioleaching harnesses microorganisms to extract metals from ores, offering an eco-friendly and cost-effective alternative to traditional smelting, which involves high-temperature melting to separate metals. This hydrometallurgical process reduces energy consumption and greenhouse gas emissions while efficiently recovering metals such as copper and gold from low-grade ores.

Pressure Oxidation (POX)

Pressure Oxidation (POX) is a hydrometallurgical process that uses controlled high-pressure and temperature conditions to break down sulfide ores, offering higher metal recovery rates compared to traditional smelting methods. POX minimizes harmful emissions and energy consumption, making it a more environmentally sustainable option in extracting metals such as gold and copper from refractory ores.

Solvent Extraction-Electrowinning (SX-EW)

Smelting involves high-temperature melting to extract metals from ores, whereas hydrometallurgical processing, particularly Solvent Extraction-Electrowinning (SX-EW), uses aqueous chemistry to selectively separate and recover metals like copper with greater environmental control and lower energy consumption. SX-EW enhances metal purity and recovery rates by combining solvent extraction for impurity removal with electrowinning to deposit high-quality cathodes, making it a preferred method in modern copper production.

Chloride Leaching

Chloride leaching in hydrometallurgical processing offers higher selectivity and lower energy consumption compared to traditional smelting techniques, enabling efficient extraction of metals such as copper, nickel, and zinc from complex ores. This method also reduces harmful emissions and minimizes environmental impact, making it a sustainable alternative in modern mineral processing operations.

Atmospheric Leaching

Atmospheric leaching in hydrometallurgical processing offers a lower-temperature, energy-efficient alternative to traditional smelting by utilizing aqueous solutions to extract metals from ores. This method reduces harmful emissions and allows selective recovery of valuable metals such as copper and gold through controlled chemical reactions under atmospheric pressure.

Flash Smelting

Flash smelting offers higher energy efficiency and reduced environmental impact compared to traditional smelting methods, utilizing oxygen-enriched air to achieve rapid oxidation of sulfide ores. Hydrometallurgical processing, relying on aqueous solutions for metal extraction, provides greater selectivity for certain metals but generally consumes more water and produces complex effluents, making flash smelting a preferred choice for large-scale copper and nickel sulfide ore treatment.

Heap Leaching

Heap leaching offers a cost-effective hydrometallurgical alternative to traditional smelting by enabling the extraction of valuable metals such as gold, copper, and uranium from low-grade ores through the percolation of leach solutions. This method reduces energy consumption and environmental impact while maximizing metal recovery rates by optimizing the solution chemistry and heap design.

Direct Smelting

Direct smelting in mining involves the thermal treatment of ores to extract metals by melting, offering higher recovery rates for complex sulfide ores compared to hydrometallurgical processing, which relies on aqueous chemistry for metal extraction. This technique reduces energy consumption and processing time, making it advantageous for recovering valuable metals such as copper, nickel, and lead from concentrates with high impurity levels.

Anode Slime Recovery

Anode slime recovery in smelting captures valuable metals like silver, gold, and platinum group metals from the electrolytic refining process, offering high purity yields but involves energy-intensive operations and environmental concerns. Hydrometallurgical processing extracts these metals through chemical leaching methods, enabling more selective recovery and lower emissions but often requires complex solution treatment and longer processing times.

Ionic Liquid Extraction

Ionic liquid extraction in hydrometallurgical processing offers enhanced selectivity and lower energy consumption compared to traditional smelting methods, making it a sustainable alternative for metal recovery. This technique leverages the unique solvation properties of ionic liquids to efficiently separate and purify metals such as copper, nickel, and rare earth elements from complex ores and electronic waste.

Smelting vs Hydrometallurgical Processing Infographic

industrydif.com

industrydif.com