Manual sampling in mining relies on human expertise to select representative ore samples, which can be time-consuming and prone to variability. Sensor-based ore sorting utilizes advanced technologies such as X-ray, infrared, or laser sensors to rapidly analyze and separate ore from waste with higher precision and efficiency. This automated approach enhances resource recovery, reduces operational costs, and minimizes environmental impact by enabling real-time decision-making.

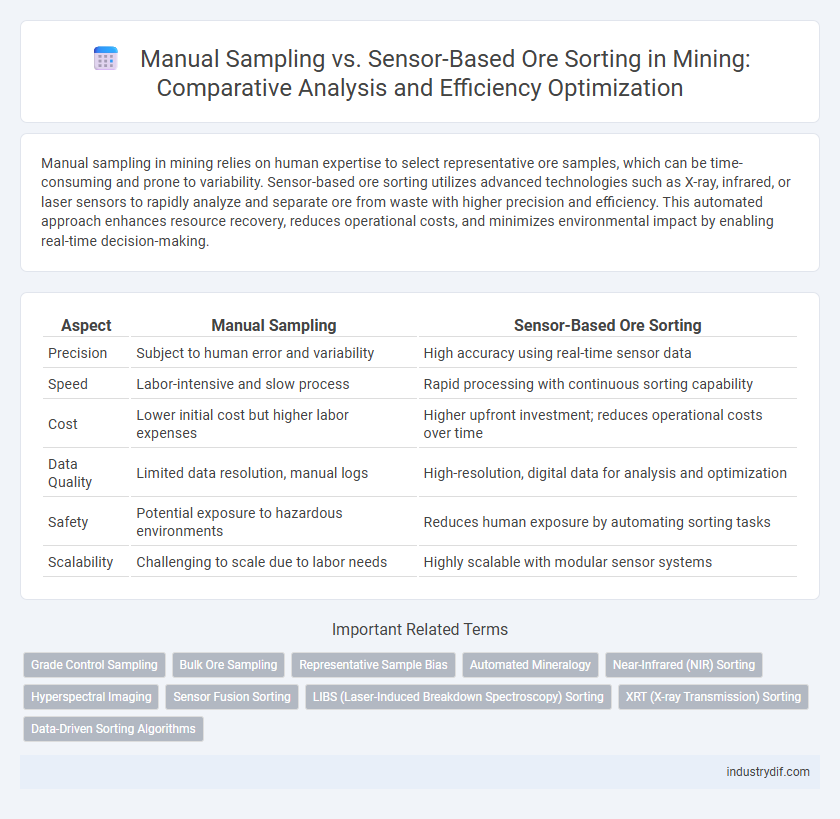

Table of Comparison

| Aspect | Manual Sampling | Sensor-Based Ore Sorting |

|---|---|---|

| Precision | Subject to human error and variability | High accuracy using real-time sensor data |

| Speed | Labor-intensive and slow process | Rapid processing with continuous sorting capability |

| Cost | Lower initial cost but higher labor expenses | Higher upfront investment; reduces operational costs over time |

| Data Quality | Limited data resolution, manual logs | High-resolution, digital data for analysis and optimization |

| Safety | Potential exposure to hazardous environments | Reduces human exposure by automating sorting tasks |

| Scalability | Challenging to scale due to labor needs | Highly scalable with modular sensor systems |

Introduction to Manual Sampling and Sensor-Based Ore Sorting

Manual sampling involves the physical collection of ore samples by trained personnel to assess the mineral content and quality, a traditional method widely used in mining operations. Sensor-based ore sorting employs advanced technologies such as X-ray fluorescence (XRF), near-infrared (NIR), and laser sensors to analyze and separate ore particles based on their chemical and physical properties in real-time. This method enhances the precision and efficiency of sample analysis, reducing human error and enabling more effective resource management in mining processes.

Key Principles of Manual Sampling in Mining

Manual sampling in mining involves the physical collection of ore samples directly from the deposit to determine mineral composition and grade variability. Key principles include ensuring representative sampling through systematic sample collection, minimizing contamination by using clean tools, and accurate documentation of sample location and characteristics to maintain data integrity. This traditional approach relies heavily on human expertise to identify ore boundaries and ensures quality control during mineral processing.

Fundamentals of Sensor-Based Ore Sorting Technology

Sensor-based ore sorting technology employs advanced sensors such as X-ray transmission, near-infrared, and laser-induced breakdown spectroscopy to analyze ore properties in real-time, enabling precise separation of valuable minerals from waste rock. This method enhances efficiency by automating the sorting process, reducing manual labor, and minimizing sampling bias inherent in traditional manual sampling. Implementing sensor-based sorting improves ore grade control, elevates recovery rates, and decreases processing costs through early-stage waste rejection.

Comparative Analysis: Accuracy and Efficiency

Manual sampling in mining relies on human observation and physical collection, often leading to variability and lower accuracy due to subjective judgment and sample representativeness issues. Sensor-based ore sorting utilizes advanced technologies such as X-ray transmission, near-infrared, and laser-induced breakdown spectroscopy to provide rapid, consistent, and precise identification of ore quality, significantly enhancing efficiency and reducing waste. While manual methods offer simplicity, sensor-based sorting produces higher accuracy by integrating real-time data analytics, increasing throughput and optimizing resource utilization in mineral processing operations.

Impact on Ore Grade and Recovery Rates

Manual sampling in mining often results in inconsistent ore grade characterization due to human error and limited sample representativity, negatively impacting recovery rates. Sensor-based ore sorting utilizes real-time data from X-ray, near-infrared, or electromagnetic sensors to accurately distinguish ore from waste material, enhancing ore grade precision and improving recovery efficiency. This technology-driven approach reduces dilution and increases the proportion of high-grade ore sent for processing, optimizing overall mine profitability.

Cost Implications: Manual vs Sensor-Based Methods

Manual sampling in mining entails higher labor costs, extensive time requirements, and increased risk of human error, leading to potential delays and additional expenses in ore grade assessment. Sensor-based ore sorting utilizes advanced technologies, such as X-ray transmission and near-infrared spectroscopy, to reduce operational costs by enhancing sorting speed, accuracy, and automation, which minimizes waste and improves yield. Investing in sensor-based methods often results in lower overall processing costs and higher economic efficiency despite initial capital expenditure on equipment.

Environmental and Safety Considerations

Manual sampling in mining exposes workers to hazardous environments, increasing health risks and potential accidents due to direct contact with ore materials. Sensor-based ore sorting reduces human exposure by automating material separation processes, minimizing dust, noise, and chemical usage, thus lowering environmental footprint and enhancing workplace safety. Adoption of sensor technologies leads to compliance with environmental regulations and promotes sustainable mining practices by reducing waste and energy consumption.

Implementation Challenges and Operational Requirements

Manual sampling in mining faces challenges such as labor intensity, inconsistent sample quality, and safety risks, requiring skilled personnel and strict quality control protocols. Sensor-based ore sorting demands significant capital investment, advanced calibration procedures, and integration with existing processing systems to ensure accurate real-time mineral detection. Operational success hinges on balancing equipment maintenance, data management, and adapting to variable ore characteristics throughout the mining cycle.

Technological Advancements in Ore Sorting

Technological advancements in ore sorting have shifted the industry from traditional manual sampling to sophisticated sensor-based ore sorting systems that enhance efficiency and precision. Sensor-based ore sorting employs technologies such as X-ray transmission, near-infrared spectroscopy, and laser-induced breakdown spectroscopy to accurately differentiate ore from waste in real time. These innovations significantly reduce processing costs, increase mineral recovery rates, and enable more sustainable mining operations by minimizing energy consumption and tailings generation.

Future Trends in Ore Processing and Mineral Analysis

Future trends in ore processing emphasize the integration of sensor-based ore sorting technology, offering enhanced precision and efficiency over traditional manual sampling methods. Advanced sensors, such as X-ray fluorescence (XRF) and near-infrared (NIR) spectroscopy, enable real-time mineral analysis and automated decision-making, reducing human error and processing time. The increasing adoption of artificial intelligence and machine learning algorithms further optimizes ore grade estimation, driving sustainable mining practices with lower operational costs and environmental impact.

Related Important Terms

Grade Control Sampling

Manual sampling in grade control provides direct, hands-on collection of representative ore samples, ensuring precise determination of mineral grades but often involves longer processing times and potential human error. Sensor-based ore sorting uses advanced technologies such as X-ray transmission and laser-induced breakdown spectroscopy to rapidly analyze and segregate ore based on grade, enhancing sampling efficiency, reducing ore dilution, and enabling real-time decision making in mining operations.

Bulk Ore Sampling

Bulk ore sampling in manual methods often suffers from heterogeneity and limited representativeness, leading to inaccurate grade estimations. Sensor-based ore sorting improves precision by rapidly analyzing physical and chemical ore properties, enabling more consistent bulk sampling and reducing processing volumes.

Representative Sample Bias

Manual sampling in mining often suffers from representative sample bias due to human error and inconsistent sample collection, leading to inaccurate ore grade estimation. Sensor-based ore sorting minimizes this bias by utilizing real-time data and automated analysis, ensuring more precise identification and extraction of valuable minerals.

Automated Mineralogy

Automated mineralogy integrates sensor-based ore sorting with advanced imaging and spectroscopy, delivering precise mineral identification and liberation analysis that surpass manual sampling's subjective limitations. This technology enhances ore grade control and reduces operational costs by enabling real-time, data-driven decisions in mineral processing.

Near-Infrared (NIR) Sorting

Near-Infrared (NIR) sorting in ore processing offers precise mineral identification by detecting subtle spectral differences, enhancing ore grade control beyond traditional manual sampling methods that rely heavily on human judgment and are prone to variability. Sensor-based ore sorting enables higher throughput and reduced processing costs by automating the segregation of valuable minerals from waste rock, optimizing recovery rates in mining operations.

Hyperspectral Imaging

Hyperspectral imaging in sensor-based ore sorting offers rapid, non-destructive analysis by capturing detailed spectral signatures that differentiate mineral compositions better than manual sampling, which is labor-intensive and prone to sampling bias. This technology enhances ore grade control, reduces processing costs, and optimizes mining efficiency by allowing precise, real-time sorting decisions based on mineralogical data.

Sensor Fusion Sorting

Sensor fusion sorting in mining integrates data from multiple sensor technologies such as X-ray fluorescence, near-infrared, and laser-induced breakdown spectroscopy to enhance ore grade control and recovery rates. This approach surpasses manual sampling by enabling real-time, precise discrimination of ore types, reducing waste throughput, and increasing overall processing efficiency.

LIBS (Laser-Induced Breakdown Spectroscopy) Sorting

Manual sampling in mining relies on human inspection and physical collection, which can introduce variability and delays in ore grade assessment, whereas LIBS (Laser-Induced Breakdown Spectroscopy) sensor-based ore sorting provides real-time, high-precision elemental analysis enabling rapid, automated separation of valuable minerals from waste. LIBS sorting enhances operational efficiency by increasing ore quality consistency, reducing processing costs, and minimizing environmental impact through targeted material handling.

XRT (X-ray Transmission) Sorting

Manual sampling in mining offers direct physical analysis but is limited by sample representativeness and time-consuming processes, whereas sensor-based ore sorting, particularly X-ray Transmission (XRT) sorting, enables high-precision mineral discrimination by detecting density variations within ore particles, enhancing feed grade control and reducing processing of waste material. XRT sorting systems significantly improve operational efficiency by enabling real-time, non-destructive analysis and increasing recovery rates while lowering overall costs in pre-concentration stages.

Data-Driven Sorting Algorithms

Manual sampling in mining relies heavily on human observation and physical sample collection, often introducing variability and potential inaccuracies. Sensor-based ore sorting utilizes advanced data-driven sorting algorithms that analyze real-time sensor data such as X-ray, near-infrared, or electromagnetic signals to accurately differentiate ore from waste, significantly improving sorting efficiency and resource recovery.

Manual Sampling vs Sensor-Based Ore Sorting Infographic

industrydif.com

industrydif.com