Flotation and bioleaching are both crucial mineral separation techniques in mining, with flotation relying on the physical properties of minerals to separate valuable materials from ore using chemicals and air bubbles. Bioleaching uses microorganisms to break down metals from ores, offering an eco-friendly alternative that reduces chemical usage and environmental impact. While flotation is faster and widely applied for sulfide ores, bioleaching is advantageous for low-grade ores and hard-to-treat minerals, making it a sustainable option for modern mining.

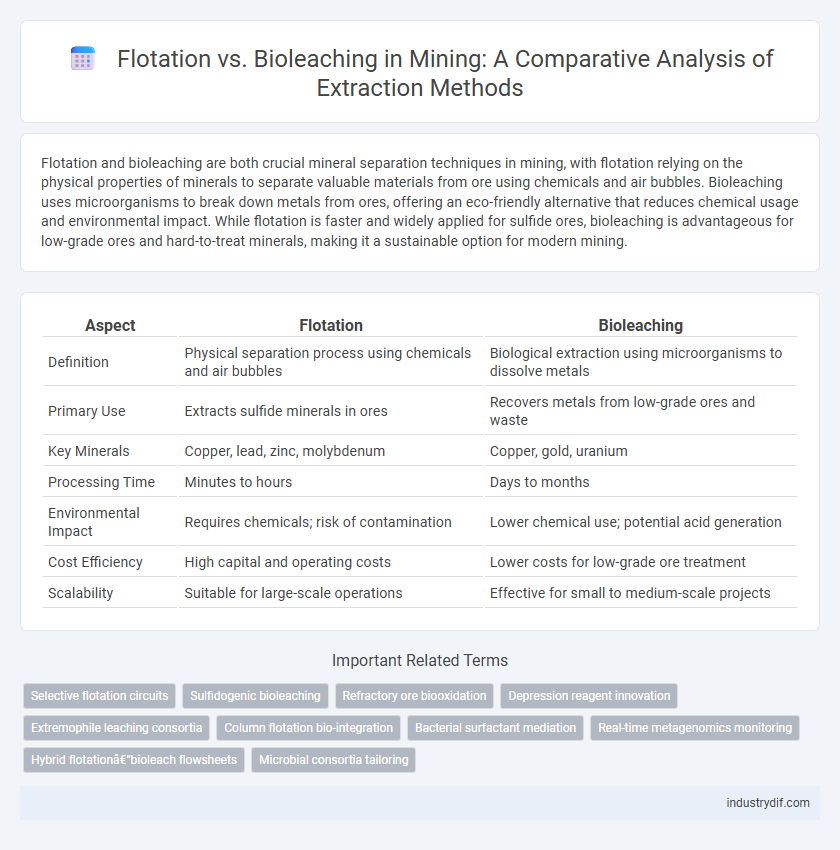

Table of Comparison

| Aspect | Flotation | Bioleaching |

|---|---|---|

| Definition | Physical separation process using chemicals and air bubbles | Biological extraction using microorganisms to dissolve metals |

| Primary Use | Extracts sulfide minerals in ores | Recovers metals from low-grade ores and waste |

| Key Minerals | Copper, lead, zinc, molybdenum | Copper, gold, uranium |

| Processing Time | Minutes to hours | Days to months |

| Environmental Impact | Requires chemicals; risk of contamination | Lower chemical use; potential acid generation |

| Cost Efficiency | High capital and operating costs | Lower costs for low-grade ore treatment |

| Scalability | Suitable for large-scale operations | Effective for small to medium-scale projects |

Introduction to Flotation and Bioleaching

Flotation is a widely used mineral processing technique that separates valuable minerals from gangue by exploiting differences in their surface properties through the use of reagents, air bubbles, and froth. Bioleaching involves the extraction of metals from ores using microbial activity, which biooxidizes sulfide minerals and liberates metals into solution, offering an environmentally friendly alternative to traditional methods. Both methods are crucial in the mining industry for enhancing metal recovery from low-grade ores and complex mineral matrices.

Principles Behind Flotation in Mining

Flotation in mining leverages differences in surface chemistry to separate valuable minerals from gangue by selectively attaching hydrophobic particles to air bubbles. This process relies on reagents such as collectors, frothers, and modifiers to enhance the hydrophobicity of target minerals, facilitating their rise to the froth layer for recovery. Flotation efficiency is influenced by factors like particle size, pulp pH, and reagent dosage, making it a versatile and widely applied technique for sulfide and non-sulfide mineral processing.

Fundamental Concepts of Bioleaching

Bioleaching involves using microorganisms to extract metals from ores through biochemical oxidation, leveraging bacteria such as Acidithiobacillus ferrooxidans to solubilize valuable minerals. Unlike flotation, which relies on physical separation techniques using reagents to create hydrophobic and hydrophilic surfaces, bioleaching exploits natural microbial metabolism for metal recovery. This process offers environmentally friendly extraction paths, especially for sulfide ores, enabling the recovery of metals like copper and gold with reduced chemical and energy consumption.

Comparative Efficiency: Flotation vs Bioleaching

Flotation exhibits higher recovery rates for sulfide ores, achieving up to 90% metal extraction, whereas bioleaching excels in processing low-grade and complex ores with efficiencies around 60-70%. The energy consumption in flotation is significantly greater due to mechanical aeration and chemical reagents, while bioleaching offers a more sustainable, lower-energy method by leveraging microbial activity. Operational costs for bioleaching tend to be lower, but the process duration is considerably longer than flotation, impacting overall throughput and economic feasibility.

Ore Types Suitable for Flotation and Bioleaching

Flotation is highly effective for sulfide ores such as chalcopyrite, galena, and sphalerite, where valuable minerals exhibit hydrophobic properties that enhance separation. Bioleaching is primarily suited for low-grade sulfide ores like chalcopyrite and arsenopyrite, benefiting from microbial activity in extracting metals like copper and gold. Oxide ores and complex polymetallic ores typically favor flotation over bioleaching due to their mineralogical characteristics and metal recovery efficiency.

Environmental Impacts: A Sustainability Perspective

Flotation generates significant tailings and chemical waste that can lead to soil and water contamination, posing long-term environmental risks. Bioleaching utilizes microorganisms to extract metals, reducing the need for harmful chemicals and enhancing sustainability through lower greenhouse gas emissions and improved resource efficiency. The environmental footprint of bioleaching is generally smaller, making it a preferable option for eco-friendly mining practices.

Economic Considerations and Cost Analysis

Flotation processes typically involve higher initial capital investments for reagents, equipment, and infrastructure but offer faster recovery rates and higher metal grades, enhancing short-term economic returns. Bioleaching requires lower capital expenditure and operational costs due to simpler setups and reduced energy consumption, making it economically viable for low-grade ores and refractory minerals. Cost analysis must account for metal price fluctuations, processing timeframes, and environmental remediation expenses, influencing the overall profitability of flotation versus bioleaching methods in mineral extraction.

Operational Challenges and Limitations

Flotation faces operational challenges such as selective mineral recovery, reagent consumption, and handling fine particles, leading to fluctuating concentrate grades and increased processing costs. Bioleaching struggles with slow extraction rates, sensitivity to environmental conditions, and the need for long retention times, which can delay production schedules. Both methods require careful management of their limitations to optimize metal recovery and maintain economic feasibility in mining operations.

Recent Technological Advancements

Recent technological advancements in flotation have focused on the development of eco-friendly reagents and automated real-time monitoring systems to enhance mineral recovery and reduce environmental impact. Bioleaching technology has advanced through the genetic engineering of acidophilic microorganisms, improving metal extraction efficiency from low-grade ores and tailings. Innovations in hybrid processes combining flotation and bioleaching are emerging, maximizing resource utilization and lowering operational costs in mineral processing.

Future Trends in Ore Processing Technologies

Future trends in ore processing technologies emphasize a shift towards integrating flotation and bioleaching to enhance metal recovery and reduce environmental impact. Researchers are developing hybrid systems that combine the high selectivity and efficiency of flotation with the eco-friendly, low-energy benefits of bioleaching. Innovations in microbial engineering and reagent design aim to optimize bioleaching rates, while advanced flotation techniques focus on processing lower-grade ores and complex mineral matrices.

Related Important Terms

Selective flotation circuits

Selective flotation circuits enhance ore processing efficiency by targeting specific minerals for separation based on their surface chemistry, achieving higher grade concentrates and improved recovery rates compared to conventional flotation. Bioleaching offers an environmentally friendly alternative by using microorganisms to extract metals from low-grade ores but often requires longer processing times and less selectivity in mineral recovery than selective flotation.

Sulfidogenic bioleaching

Sulfidogenic bioleaching utilizes sulfate-reducing bacteria to convert metal sulfides into soluble forms, offering a more environmentally friendly and cost-effective alternative to traditional flotation methods. Unlike flotation, which relies on physical separation, sulfidogenic bioleaching enhances metal recovery through biochemical reactions, minimizing reagent use and tailings toxicity.

Refractory ore biooxidation

Flotation efficiently concentrates sulfide minerals by selectively separating valuable particles but often fails to fully extract metals from refractory ores rich in complex sulfides and arsenopyrite. Bioleaching enhances metal recovery in refractory ore biooxidation by employing specialized microorganisms to oxidize sulfide minerals, breaking down the ore matrix and enabling subsequent extraction processes such as cyanidation or flotation.

Depression reagent innovation

Depression reagent innovation in flotation enhances the selective separation of valuable minerals by inhibiting unwanted sulfides, improving ore grade and recovery rates. Bioleaching uses microbial agents to bio-depress specific minerals, offering an eco-friendly alternative that complements flotation reagents for complex ore processing.

Extremophile leaching consortia

Extremophile leaching consortia in bioleaching exploit specialized microorganisms to enhance metal recovery from ores under harsh conditions, offering increased selectivity and eco-friendly processing compared to traditional flotation methods that rely on physical-chemical separation. The microbial activity within bioleaching consortia facilitates the breakdown of sulfide minerals at low temperatures and acidic pH, reducing energy consumption and hazardous reagent use common in flotation.

Column flotation bio-integration

Column flotation bio-integration enhances mineral recovery by combining microbial activity with hydrodynamic conditions to improve particle-bubble attachment efficiency. This technique leverages bio-oxidation processes to selectively target sulfide minerals, offering a sustainable alternative to traditional flotation and bioleaching methods with increased metal extraction rates and reduced environmental impact.

Bacterial surfactant mediation

Bacterial surfactants in bioleaching enhance metal recovery by increasing the hydrophobicity of mineral surfaces, promoting efficient attachment of microbes and facilitating metal solubilization. In contrast, flotation relies on chemical reagents to alter surface properties for mineral separation, lacking the biological mediation that improves selectivity and environmental sustainability seen in bioleaching.

Real-time metagenomics monitoring

Real-time metagenomics monitoring in flotation enhances microbial community analysis, optimizing reagent use and recovery rates by providing immediate insights into biofilm dynamics and mineral-microbe interactions. In bioleaching, this technology enables continuous tracking of microbial consortia, facilitating precise control over biooxidation processes and improving metal extraction efficiency through adaptive process management.

Hybrid flotation–bioleach flowsheets

Hybrid flotation-bioleach flowsheets combine the physical separation efficiency of flotation with the microbial oxidation processes of bioleaching to enhance metal recovery from low-grade ores and complex sulfide minerals. This integration optimizes mineral liberation and metal extraction, reducing environmental impact and increasing overall process sustainability in mining operations.

Microbial consortia tailoring

Microbial consortia tailoring enhances bioleaching efficiency by optimizing specific bacteria and archaea communities to target sulfide minerals, offering a sustainable alternative to flotation's physical separation method. This biological approach reduces environmental impact and improves metal recovery rates in complex ores where flotation struggles with selectivity.

Flotation vs Bioleaching Infographic

industrydif.com

industrydif.com