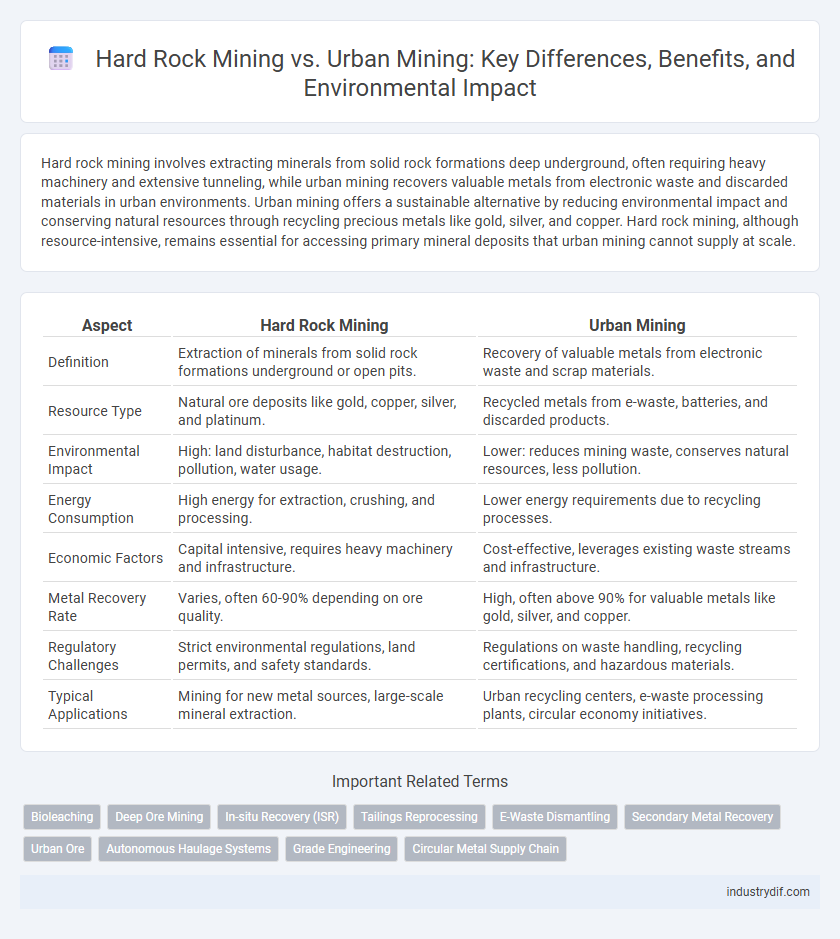

Hard rock mining involves extracting minerals from solid rock formations deep underground, often requiring heavy machinery and extensive tunneling, while urban mining recovers valuable metals from electronic waste and discarded materials in urban environments. Urban mining offers a sustainable alternative by reducing environmental impact and conserving natural resources through recycling precious metals like gold, silver, and copper. Hard rock mining, although resource-intensive, remains essential for accessing primary mineral deposits that urban mining cannot supply at scale.

Table of Comparison

| Aspect | Hard Rock Mining | Urban Mining |

|---|---|---|

| Definition | Extraction of minerals from solid rock formations underground or open pits. | Recovery of valuable metals from electronic waste and scrap materials. |

| Resource Type | Natural ore deposits like gold, copper, silver, and platinum. | Recycled metals from e-waste, batteries, and discarded products. |

| Environmental Impact | High: land disturbance, habitat destruction, pollution, water usage. | Lower: reduces mining waste, conserves natural resources, less pollution. |

| Energy Consumption | High energy for extraction, crushing, and processing. | Lower energy requirements due to recycling processes. |

| Economic Factors | Capital intensive, requires heavy machinery and infrastructure. | Cost-effective, leverages existing waste streams and infrastructure. |

| Metal Recovery Rate | Varies, often 60-90% depending on ore quality. | High, often above 90% for valuable metals like gold, silver, and copper. |

| Regulatory Challenges | Strict environmental regulations, land permits, and safety standards. | Regulations on waste handling, recycling certifications, and hazardous materials. |

| Typical Applications | Mining for new metal sources, large-scale mineral extraction. | Urban recycling centers, e-waste processing plants, circular economy initiatives. |

Definition and Scope of Hard Rock Mining

Hard rock mining involves the extraction of precious metals and minerals from solid rock deposits deep beneath the earth's surface, primarily targeting ores such as gold, silver, copper, and iron. This traditional mining method requires extensive drilling, blasting, and excavation to access valuable mineral veins within hard rock formations. The scope of hard rock mining extends to large-scale underground and open-pit operations, emphasizing the removal of ore-bearing rock for processing and refinement.

Understanding Urban Mining: An Overview

Urban mining involves extracting valuable metals and minerals from electronic waste, industrial scrap, and discarded products, presenting a sustainable alternative to traditional hard rock mining. It reduces environmental impact by recycling materials like gold, copper, and rare earth elements from electronic devices and infrastructure components. As global demand for critical minerals rises, urban mining plays a crucial role in resource recovery and circular economy strategies.

Key Processes in Hard Rock Mining

Hard rock mining involves extracting valuable minerals from solid rock formations through processes such as drilling, blasting, and crushing to break down ore into manageable pieces. Key procedures include underground or open-pit excavation, followed by ore transportation to processing facilities for smelting, refining, and recovery of metals like gold, copper, and iron. This method requires specialized equipment and precise geological analysis to maximize resource extraction efficiency and minimize environmental impact.

Methods and Technologies in Urban Mining

Urban mining employs advanced sensor-based sorting, robotics, and hydrometallurgical techniques to extract valuable metals from electronic waste and obsolete infrastructure, contrasting with the traditional blasting and excavation used in hard rock mining. Technologies such as automated shredding, magnetic separation, and bioleaching optimize recovery rates and reduce environmental impact. This method leverages circular economy principles by recovering precious elements like gold, copper, and rare earth metals from urban sources.

Environmental Impact: Hard Rock vs Urban Mining

Hard rock mining generates significant environmental degradation through habitat destruction, soil erosion, and toxic tailings, which contribute to water pollution and biodiversity loss. Urban mining reduces the ecological footprint by recycling valuable metals from electronic waste and discarded materials, lowering the demand for virgin ore extraction. This approach minimizes greenhouse gas emissions and conserves natural resources by diverting waste from landfills and reducing energy-intensive mining processes.

Resource Efficiency and Material Recovery

Hard rock mining involves extracting minerals from solid rock, often resulting in significant waste and environmental disruption, while urban mining recovers valuable metals from electronic waste and other urban materials, offering higher resource efficiency. Urban mining enhances material recovery rates by recycling metals like gold, copper, and rare earth elements with lower energy consumption compared to traditional hard rock methods. This approach reduces dependency on virgin ore extraction, minimizes ecological impact, and supports sustainable resource management in the mining industry.

Economic Implications and Market Trends

Hard rock mining demands significant upfront capital investment and operational costs due to extensive excavation and processing, but it yields high-purity metals crucial for industrial applications, driving steady market demand. Urban mining leverages electronic waste and recycled materials, offering lower extraction costs and reduced environmental impact, aligning with growing circular economy trends and regulatory incentives. Market data indicates rising investor interest in urban mining firms, reflecting increased emphasis on sustainable sourcing amid fluctuating commodity prices in traditional mining sectors.

Regulatory Frameworks and Compliance

Hard rock mining is subject to stringent environmental regulations and requires extensive permits to manage land use, waste disposal, and water contamination, often facing prolonged regulatory approval processes. Urban mining, involving the recovery of metals from electronic waste and recycled materials, operates under different compliance standards focusing on hazardous waste handling and material recovery efficiency, often benefiting from incentives promoting circular economy practices. Regulatory frameworks for both sectors emphasize sustainability and pollution control, but urban mining tends to have more flexible policies encouraging innovation and reduced environmental impact.

Technological Innovations Shaping Both Sectors

Technological innovations such as automated drilling systems and real-time geological data analysis are revolutionizing hard rock mining by enhancing precision and safety. In urban mining, advancements in sensor technologies and artificial intelligence enable efficient extraction of valuable metals from electronic waste, reducing environmental impact. Both sectors leverage innovations in material recovery and waste management to optimize resource utilization and sustainability.

Future Prospects: Synergies and Challenges

Hard rock mining continues to supply critical minerals essential for technology and infrastructure but faces environmental and resource depletion challenges that limit long-term sustainability. Urban mining offers a promising complementary approach by reclaiming valuable metals from electronic waste, reducing ecological impact and resource scarcity. Integrating advanced technologies in both sectors can enhance material recovery rates and foster a circular economy, yet overcoming regulatory, economic, and technological barriers remains crucial for maximizing their synergistic potential.

Related Important Terms

Bioleaching

Bioleaching in hard rock mining involves using microorganisms to extract metals from sulfide ores, offering a more eco-friendly alternative to traditional smelting, while urban mining leverages bioleaching to recover valuable metals from electronic waste, reducing landfill impact and resource depletion. The efficiency of bioleaching depends on factors like pH, temperature, and microbial species, making it a sustainable method for both primary extraction and secondary metal recovery in circular economy practices.

Deep Ore Mining

Deep ore mining in hard rock environments involves extracting mineral deposits from solid rock formations found deep beneath the surface, requiring advanced drilling and blasting technologies. Urban mining recovers valuable metals from electronic waste and scrap materials, offering a sustainable alternative with lower environmental impact compared to the energy-intensive processes of deep ore extraction.

In-situ Recovery (ISR)

In-situ recovery (ISR) in mining presents a less invasive alternative to traditional hard rock mining by dissolving valuable minerals directly within ore bodies and pumping the solution to the surface, minimizing environmental disruption and lowering operational costs. Urban mining complements ISR by recycling metals from electronic waste, batteries, and scrap materials, effectively reducing the demand for new extraction and promoting sustainable resource management.

Tailings Reprocessing

Tailings reprocessing in hard rock mining involves extracting valuable minerals from leftover ore residues, significantly reducing environmental impact and enhancing resource efficiency. Urban mining reclaims precious metals from electronic waste and industrial tailings, offering a sustainable alternative by minimizing raw material extraction and reducing landfill pressure.

E-Waste Dismantling

Hard rock mining extracts valuable minerals from ore deposits deep underground, often causing significant environmental disruption and high energy consumption, whereas urban mining involves the recovery of precious metals from e-waste dismantling, promoting sustainable resource management and reducing landfill waste. E-waste dismantling in urban mining efficiently recovers rare earth elements, gold, copper, and palladium, offering a more eco-friendly alternative that supports circular economy principles and reduces reliance on virgin mineral extraction.

Secondary Metal Recovery

Hard rock mining extracts metals directly from ore deposits, often causing significant environmental disruption and high energy consumption, whereas urban mining focuses on secondary metal recovery by reclaiming valuable metals from electronic waste and scrap materials, promoting sustainability and reducing reliance on virgin resources. Secondary metal recovery through urban mining enhances resource efficiency by recovering metals such as copper, gold, and rare earth elements, lowering the carbon footprint compared to traditional hard rock mining.

Urban Ore

Urban ore extraction leverages recyclable metals from electronic waste, reducing the environmental impact associated with traditional hard rock mining and conserving natural resources. This sustainable approach in urban mining prioritizes efficient material recovery from discarded devices, addressing metal scarcity while minimizing habitat disruption and energy consumption.

Autonomous Haulage Systems

Autonomous Haulage Systems (AHS) enhance operational efficiency and safety in both hard rock mining and urban mining by automating ore transport, reducing human error and downtime. In hard rock mining, AHS optimizes extraction from deep, complex ore bodies, while in urban mining, it supports the systematic recovery of valuable metals from electronic waste and urban materials.

Grade Engineering

Grade engineering in hard rock mining involves extracting high-grade ore from underground deposits, optimizing mineral concentration through precise geological targeting and ore sorting technologies. Urban mining enhances resource efficiency by recovering valuable metals from electronic waste and industrial scrap, leveraging advanced separation techniques to maximize metal purity and reduce environmental impact.

Circular Metal Supply Chain

Hard rock mining extracts metals from natural ore deposits, often causing significant environmental disruption, whereas urban mining recovers valuable metals from electronic waste, promoting sustainability by repurposing materials within the circular metal supply chain. Urban mining enhances resource efficiency and reduces reliance on finite natural reserves by enabling continuous metal recovery and recycling in the circular economy.

Hard Rock Mining vs Urban Mining Infographic

industrydif.com

industrydif.com