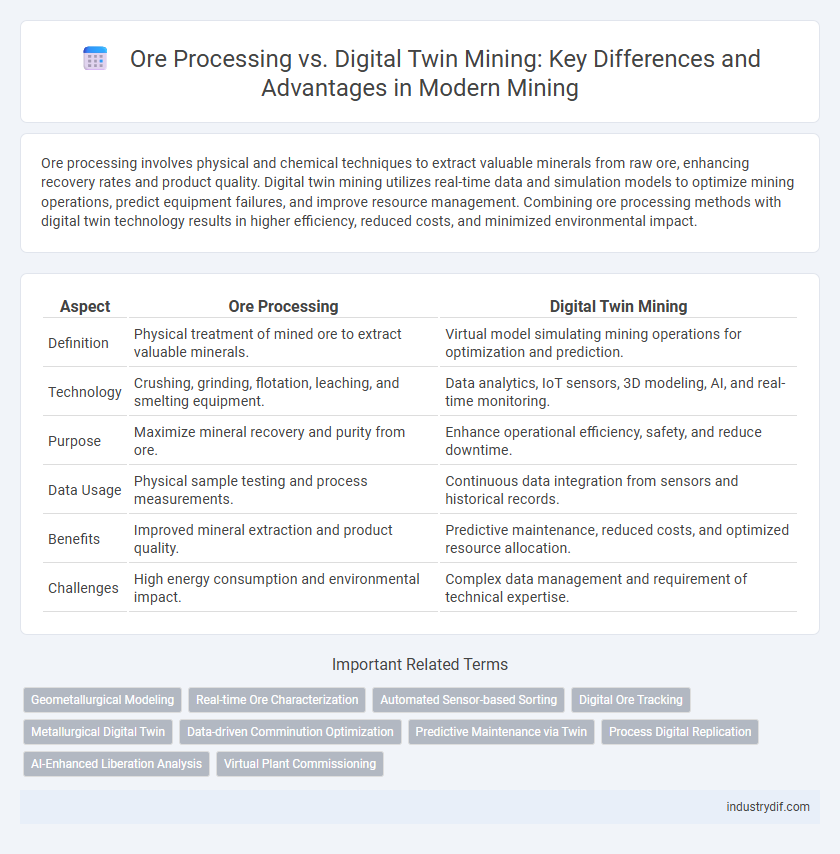

Ore processing involves physical and chemical techniques to extract valuable minerals from raw ore, enhancing recovery rates and product quality. Digital twin mining utilizes real-time data and simulation models to optimize mining operations, predict equipment failures, and improve resource management. Combining ore processing methods with digital twin technology results in higher efficiency, reduced costs, and minimized environmental impact.

Table of Comparison

| Aspect | Ore Processing | Digital Twin Mining |

|---|---|---|

| Definition | Physical treatment of mined ore to extract valuable minerals. | Virtual model simulating mining operations for optimization and prediction. |

| Technology | Crushing, grinding, flotation, leaching, and smelting equipment. | Data analytics, IoT sensors, 3D modeling, AI, and real-time monitoring. |

| Purpose | Maximize mineral recovery and purity from ore. | Enhance operational efficiency, safety, and reduce downtime. |

| Data Usage | Physical sample testing and process measurements. | Continuous data integration from sensors and historical records. |

| Benefits | Improved mineral extraction and product quality. | Predictive maintenance, reduced costs, and optimized resource allocation. |

| Challenges | High energy consumption and environmental impact. | Complex data management and requirement of technical expertise. |

Understanding Ore Processing in Modern Mining

Ore processing in modern mining involves the extraction and refinement of valuable minerals from raw ore using advanced techniques such as crushing, grinding, and flotation. Digital twin mining enhances this process by creating a virtual replica of mining operations, enabling real-time monitoring, optimization, and predictive maintenance of ore processing equipment. Integration of digital twin technologies improves ore recovery rates and operational efficiency, reducing costs and environmental impact.

Introduction to Digital Twin Technology in Mining

Digital Twin technology in mining creates a virtual replica of ore processing systems, enabling real-time monitoring and optimization of operations. By simulating physical mining environments and equipment, this technology enhances predictive maintenance, reduces downtime, and improves resource recovery rates. Integration of digital twins with ore processing data drives more efficient decision-making and operational transparency across mining projects.

Key Differences: Ore Processing vs. Digital Twin Mining

Ore processing involves physical and chemical methods to extract valuable minerals from raw ore, focusing on crushing, grinding, separation, and refining techniques to maximize recovery rates. Digital twin mining employs advanced simulation and real-time data integration to create virtual replicas of mining operations, enabling predictive maintenance, process optimization, and reduced operational risks. Key differences lie in ore processing being a tangible, hands-on phase of mineral extraction, whereas digital twin mining emphasizes virtual modeling and data-driven decision-making for operational efficiency.

Enhancing Operational Efficiency: Traditional vs. Digital Approaches

Ore processing relies heavily on physical methods like crushing, grinding, and flotation to extract valuable minerals, which can be time-consuming and resource-intensive. Digital twin mining leverages real-time data simulations and predictive analytics to optimize equipment performance and anticipate maintenance needs, significantly reducing downtime. This data-driven approach enhances operational efficiency by enabling proactive decision-making and minimizing resource wastage compared to traditional ore processing techniques.

Environmental Impact: Ore Processing and Digital Twins

Ore processing methods often generate significant environmental impacts, including habitat destruction, water contamination from tailings, and high energy consumption. Digital twin technology in mining enables real-time monitoring and simulation of ore processing operations, optimizing resource use and reducing waste generation. Implementing digital twins decreases environmental footprints by enhancing efficiency, minimizing emissions, and supporting sustainable mining practices.

Cost Analysis: Conventional Processing vs. Digital Twin Solutions

Conventional ore processing involves significant operational costs including labor, energy consumption, and equipment maintenance, often leading to unpredictable expenses due to process inefficiencies. Digital Twin mining technology enables real-time data analytics and process simulation, reducing downtime and optimizing resource allocation, which can lower overall operational expenditures by up to 25%. Cost analysis reveals that integrating Digital Twin solutions leads to improved budget forecasting and reduced waste, demonstrating higher return on investment compared to traditional processing methods.

Data Integration in Mining Processes

Ore processing relies heavily on real-time data integration from crushers, mills, and flotation cells to optimize recovery rates and minimize energy consumption. Digital twin mining enhances this approach by creating virtual replicas of physical mining assets, enabling seamless integration of operational, geological, and sensor data for predictive maintenance and process optimization. Advanced data integration in digital twins drives improved decision-making and efficiency across the entire mining value chain.

Predictive Maintenance: Role of Digital Twins in Ore Processing

Digital twins in ore processing enable predictive maintenance by continuously monitoring equipment conditions and simulating various mining scenarios, reducing unexpected downtime and operational costs. Real-time data integration allows precise prediction of wear and tear on machinery, optimizing maintenance schedules and enhancing equipment lifespan. This advanced approach improves ore extraction efficiency and reliability, driving higher productivity in mining operations.

Future Trends: Automation and Virtualization in Mining

Ore processing increasingly integrates advanced automation technologies, enhancing efficiency and reducing operational costs through real-time data analytics and precision control systems. Digital twin mining leverages virtualization to create dynamic, virtual replicas of mining operations, enabling predictive maintenance and optimized resource management. Future trends emphasize the convergence of automation and digital twins, driving smarter, more sustainable mining practices through continuous innovation and digital transformation.

Challenges and Opportunities in Adopting Digital Twin Mining

Challenges in adopting digital twin mining include integration complexity with legacy ore processing systems, data accuracy demands, and high initial investment costs. Opportunities arise from enhanced real-time monitoring, predictive maintenance, and optimized resource extraction, leading to improved operational efficiency and reduced environmental impact. Digital twin technology enables simulation of ore processing scenarios, facilitating better decision-making and minimizing downtime.

Related Important Terms

Geometallurgical Modeling

Ore processing relies on traditional physical sampling and laboratory testing to determine mineral composition and optimize extraction methods, while digital twin mining integrates real-time sensor data and geometallurgical modeling to create dynamic, predictive simulations of ore bodies. Geometallurgical modeling within digital twins enhances ore processing efficiency by accurately forecasting variability in mineral properties and metallurgical responses, enabling adaptive operational strategies and reduced processing costs.

Real-time Ore Characterization

Real-time ore characterization in ore processing enhances extraction efficiency by continuously analyzing mineral composition during crushing and grinding stages, enabling precise process adjustments. Digital twin mining leverages real-time data to simulate ore behavior and optimize processing parameters, reducing downtime and improving recovery rates through advanced predictive analytics.

Automated Sensor-based Sorting

Automated sensor-based sorting in ore processing enhances mineral recovery by precisely identifying and segregating valuable materials, reducing waste and operational costs. Digital twin mining integrates real-time sensor data with virtual simulations to optimize sorting efficiency, enabling predictive maintenance and dynamic process adjustments for improved yield and sustainability.

Digital Ore Tracking

Digital ore tracking leverages real-time data integration and advanced analytics to enhance visibility and accuracy throughout the ore processing lifecycle, reducing losses and improving overall yield. Unlike traditional ore processing methods, digital twin mining creates a virtual replica of the mining operation, enabling predictive maintenance, process optimization, and dynamic decision-making in ore management.

Metallurgical Digital Twin

Metallurgical Digital Twins revolutionize ore processing by simulating real-time chemical, physical, and thermal reactions within the mineral extraction and refining stages to optimize yield and reduce operational costs. Integrating sensor data and advanced analytics, these digital replicas enable predictive maintenance, enhance process control, and minimize environmental impact compared to traditional ore processing techniques.

Data-driven Comminution Optimization

Data-driven comminution optimization integrates real-time data from digital twin mining models to enhance ore processing efficiency by accurately predicting fragmentation and energy consumption. Leveraging machine learning algorithms within these digital twins enables continuous adjustment of crusher and mill parameters, minimizing operational costs and maximizing throughput compared to traditional ore processing methods.

Predictive Maintenance via Twin

Ore processing efficiency significantly improves through the integration of digital twin mining technology, enabling real-time monitoring and predictive maintenance that reduces equipment downtime and operational costs. Predictive maintenance via digital twins uses sensor data and machine learning algorithms to anticipate failures, optimize maintenance schedules, and extend the lifespan of critical mining machinery.

Process Digital Replication

Ore processing traditionally relies on physical methods to extract valuable minerals, whereas digital twin mining creates a virtual replica of the entire mining process to simulate, monitor, and optimize operations in real time. Process digital replication enables predictive maintenance, reduces operational costs, and enhances decision-making by providing accurate, dynamic insights into ore processing workflows.

AI-Enhanced Liberation Analysis

AI-enhanced liberation analysis in ore processing leverages digital twin mining to simulate and optimize mineral separation with high precision, reducing waste and improving recovery rates. Digital twins integrate real-time data and machine learning algorithms to model ore behavior, enabling predictive adjustments that boost efficiency and lower operational costs.

Virtual Plant Commissioning

Ore processing efficiency can be significantly enhanced through Digital Twin Mining technology, which enables Virtual Plant Commissioning by creating an accurate simulation of the plant's operations. This approach reduces downtime and operational risks by allowing engineers to test and optimize the processing workflows in a virtual environment before physical implementation.

Ore Processing vs Digital Twin Mining Infographic

industrydif.com

industrydif.com