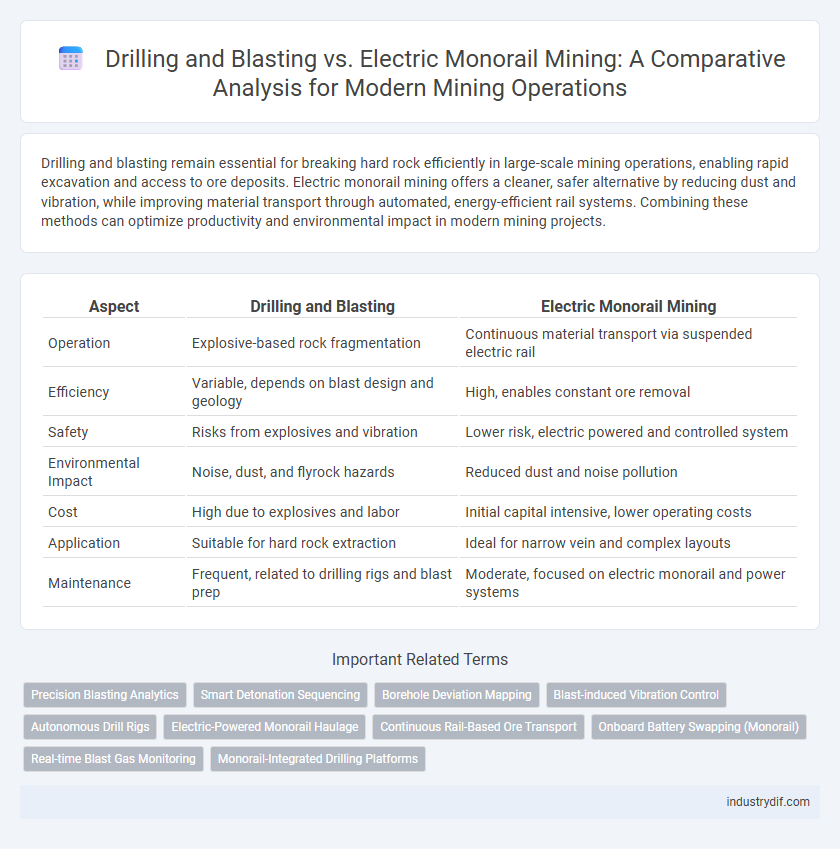

Drilling and blasting remain essential for breaking hard rock efficiently in large-scale mining operations, enabling rapid excavation and access to ore deposits. Electric monorail mining offers a cleaner, safer alternative by reducing dust and vibration, while improving material transport through automated, energy-efficient rail systems. Combining these methods can optimize productivity and environmental impact in modern mining projects.

Table of Comparison

| Aspect | Drilling and Blasting | Electric Monorail Mining |

|---|---|---|

| Operation | Explosive-based rock fragmentation | Continuous material transport via suspended electric rail |

| Efficiency | Variable, depends on blast design and geology | High, enables constant ore removal |

| Safety | Risks from explosives and vibration | Lower risk, electric powered and controlled system |

| Environmental Impact | Noise, dust, and flyrock hazards | Reduced dust and noise pollution |

| Cost | High due to explosives and labor | Initial capital intensive, lower operating costs |

| Application | Suitable for hard rock extraction | Ideal for narrow vein and complex layouts |

| Maintenance | Frequent, related to drilling rigs and blast prep | Moderate, focused on electric monorail and power systems |

Introduction to Drilling and Blasting in Mining

Drilling and blasting remain essential techniques in mining operations, involving precision drilling of blast holes followed by controlled detonation to fragment rock formations for easier extraction. This method enables efficient rock breaking in hard rock environments, optimizing fragmentation size for subsequent loading and hauling processes. Drilling and blasting continue to be integral in conventional mining compared to electric monorail mining, which emphasizes mechanized material transport rather than rock fragmentation.

Electric Monorail Mining: An Emerging Technology

Electric monorail mining represents an emerging technology revolutionizing underground excavation by offering enhanced safety, increased efficiency, and reduced environmental impact compared to traditional drilling and blasting methods. This innovative approach utilizes electric-powered monorail systems to transport materials and miners seamlessly within confined spaces, minimizing vibration and rock damage commonly associated with blasting. The integration of electric monorail mining technology promotes continuous operation, lowers operational costs, and supports sustainable mining practices through reduced emissions and noise pollution.

Comparative Overview: Traditional vs. Modern Mining Methods

Drilling and blasting remain dominant in traditional mining for their effectiveness in fragmenting hard rock and accessing deep ore deposits, but they generate significant vibrations, dust, and safety risks. Electric monorail mining represents a modern method offering precise ore extraction with reduced environmental impact, enhanced worker safety, and improved operational efficiency through automated material handling systems. Comparative data indicate that electric monorail systems can reduce ventilation costs by up to 30% and increase productivity by 20% compared to conventional drilling and blasting techniques.

Efficiency and Productivity Analysis

Drilling and blasting offer rapid rock fragmentation ideal for large-scale mining operations, but often generate significant vibration and require extensive secondary processing. Electric monorail mining systems enhance efficiency by enabling continuous ore transport with reduced downtime and lower environmental impact, optimizing productivity in underground settings. Comparative analysis shows electric monorail mining reduces cycle times and operational costs, significantly boosting overall mine productivity compared to traditional drilling and blasting methods.

Environmental Impact Assessment

Drilling and blasting in mining generate significant dust, noise, and vibrations, negatively impacting local ecosystems and air quality. Electric monorail mining reduces these emissions by enabling quieter, dust-free material transport with lower energy consumption and minimal land disturbance. Environmental impact assessments highlight electric monorail systems as a sustainable alternative, improving air quality and reducing habitat disruption compared to traditional blasting methods.

Safety Standards and Worker Health

Drilling and blasting in mining pose significant risks due to flying debris, ground vibrations, and exposure to hazardous gases, necessitating stringent safety standards and protective measures for worker health. Electric monorail mining systems significantly reduce these hazards by minimizing dust, noise, and vibration levels, thereby enhancing respiratory health and overall safety compliance. Implementation of electric monorail technology aligns with modern occupational safety regulations aimed at reducing accidents and long-term health issues among miners.

Cost Implications and Investment Factors

Drilling and blasting in mining involves significant costs related to explosives, equipment maintenance, and labor, with expenses fluctuating based on rock hardness and blast design complexity. Electric monorail mining systems require substantial upfront investment for infrastructure, such as track installation and electric vehicles, but offer lower operational costs through reduced energy consumption and maintenance. Long-term cost efficiency of electric monorails depends on mine scale and lifespan, while drilling and blasting remain cost-effective for smaller or irregular deposits.

Adaptability to Different Ore Bodies

Drilling and blasting offer high adaptability to various ore bodies by enabling customized blast patterns and fragmentation sizes suited for heterogeneous rock formations. Electric monorail mining systems provide efficient ore transport but require more uniform tunnel profiles, limiting their flexibility in irregular or complex ore bodies. Selecting the appropriate method depends on ore body geometry, with drilling and blasting favored for variable structures and electric monorails optimized for consistent, predictable mine layouts.

Technological Innovations and Automation

Drilling and blasting technologies incorporate advanced automation systems, such as precision drill rigs and real-time blast monitoring, improving safety and fragmentation control in mining operations. Electric monorail mining employs automated rail-guided vehicles and remote-operated equipment, enabling efficient ore transportation with reduced emissions and operational costs. Both methods leverage technological innovations to enhance productivity, minimize environmental impact, and increase worker safety through automation and smart systems integration.

Future Trends in Mining Operations

Drilling and blasting remain fundamental in mining for efficient rock fragmentation, but electric monorail mining is gaining traction due to its enhanced safety, reduced environmental impact, and improved automation capabilities. Future trends emphasize integrating electric monorail systems with AI-driven operational control, enabling real-time monitoring, precision targeting, and lower energy consumption. This shift supports sustainable mining practices and aligns with global efforts to minimize carbon footprints while optimizing productivity.

Related Important Terms

Precision Blasting Analytics

Precision blasting analytics in drilling and blasting optimize fragmentation by analyzing blast patterns, rock properties, and vibration data to enhance ore recovery and reduce downstream processing costs. In contrast, electric monorail mining relies on automated material transport but lacks the granular control over fragmentation that precision blasting analytics provide for improved operational efficiency.

Smart Detonation Sequencing

Smart detonation sequencing in drilling and blasting enhances precision by optimizing blast timing to improve fragmentation and reduce vibration, compared to the continuous and controlled material transport offered by electric monorail mining systems. This advanced sequencing technology maximizes efficiency in rock breakage while minimizing environmental impact, making it a critical component in modern mining operations focused on safety and productivity.

Borehole Deviation Mapping

Borehole deviation mapping plays a crucial role in optimizing drilling and blasting operations by accurately tracking the trajectory of blast holes, ensuring precise fragmentation and minimizing overbreak. Electric monorail mining systems, while efficient for material transport, lack direct integration with borehole deviation mapping technology, limiting their impact on geotechnical accuracy during the blast planning phase.

Blast-induced Vibration Control

Blast-induced vibration control in drilling and blasting relies on precise charge design and timing to minimize seismic impact, ensuring structural stability and compliance with regulatory limits; electric monorail mining reduces vibration by eliminating explosive use, providing a continuous and controlled rock removal process. Compared to traditional blasting, electric monorail technology offers enhanced safety and environmental benefits while maintaining efficient ore extraction in vibration-sensitive mining operations.

Autonomous Drill Rigs

Autonomous drill rigs in drilling and blasting operations enhance precision and safety by enabling remote-controlled excavation, reducing human exposure to hazardous environments. Compared to electric monorail mining, autonomous drilling offers greater flexibility in complex ore bodies, accelerating development while optimizing resource extraction through advanced GPS and sensor integration.

Electric-Powered Monorail Haulage

Electric-powered monorail haulage in mining offers a sustainable alternative to traditional drilling and blasting methods by reducing emissions and enhancing operational efficiency through continuous, automated transport of ore. This system leverages electric motors for reliable, low-maintenance haulage, minimizing environmental impact while improving safety and productivity in underground mining operations.

Continuous Rail-Based Ore Transport

Continuous rail-based ore transport enhances operational efficiency by providing a steady flow of materials directly from the drilling and blasting zones, minimizing downtime associated with intermittent loading cycles typical of electric monorail systems. The integration of continuous rail transport reduces ore handling costs and increases overall productivity by maintaining uninterrupted material movement in underground mining operations.

Onboard Battery Swapping (Monorail)

Onboard battery swapping in electric monorail mining significantly reduces downtime and enhances operational efficiency compared to traditional drilling and blasting methods, which involve longer cycles and higher maintenance. This technology enables rapid battery exchange directly on the monorail system, increasing productivity while minimizing environmental impact and improving worker safety in underground mining operations.

Real-time Blast Gas Monitoring

Real-time blast gas monitoring during drilling and blasting operations enhances safety by providing immediate detection of hazardous gases like CO and NOx, preventing underground gas build-ups that could lead to explosions or health risks. In electric monorail mining, continuous gas monitoring integrates with automated ventilation control systems, optimizing air quality and ensuring regulatory compliance while maintaining operational efficiency.

Monorail-Integrated Drilling Platforms

Monorail-integrated drilling platforms enhance mining efficiency by combining precise drilling capabilities with streamlined material transport, reducing operational downtime compared to traditional drilling and blasting methods. Electric monorail mining systems offer improved environmental sustainability and worker safety through reduced emissions and controlled rock fragmentation, positioning them as a cutting-edge alternative in underground mining operations.

Drilling and Blasting vs Electric Monorail Mining Infographic

industrydif.com

industrydif.com