Surface mining involves removing large quantities of overburden to access mineral deposits near the earth's surface, offering high productivity and easier access to resources. Block caving is an underground mining method where the ore body is undercut, causing it to collapse and be collected, which is highly efficient for extracting massive, low-grade ore bodies with minimal surface disturbance. Choosing between these methods depends on ore depth, grade, and environmental considerations, with surface mining favoring shallow deposits and block caving suited for deeper, extensive ore bodies.

Table of Comparison

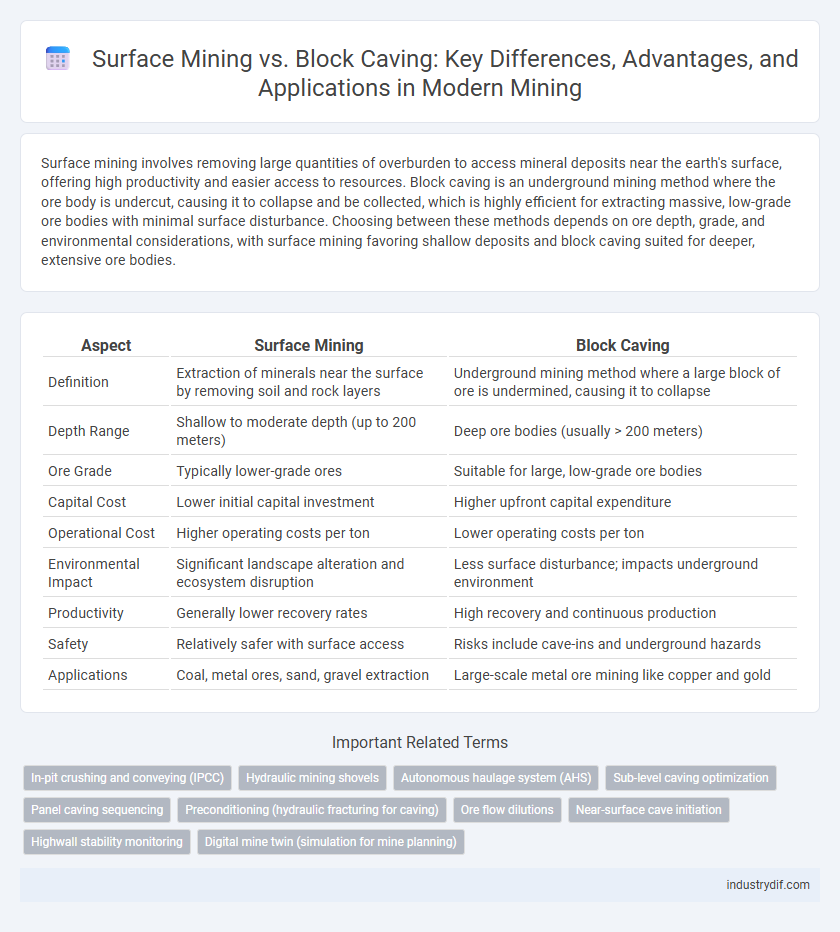

| Aspect | Surface Mining | Block Caving |

|---|---|---|

| Definition | Extraction of minerals near the surface by removing soil and rock layers | Underground mining method where a large block of ore is undermined, causing it to collapse |

| Depth Range | Shallow to moderate depth (up to 200 meters) | Deep ore bodies (usually > 200 meters) |

| Ore Grade | Typically lower-grade ores | Suitable for large, low-grade ore bodies |

| Capital Cost | Lower initial capital investment | Higher upfront capital expenditure |

| Operational Cost | Higher operating costs per ton | Lower operating costs per ton |

| Environmental Impact | Significant landscape alteration and ecosystem disruption | Less surface disturbance; impacts underground environment |

| Productivity | Generally lower recovery rates | High recovery and continuous production |

| Safety | Relatively safer with surface access | Risks include cave-ins and underground hazards |

| Applications | Coal, metal ores, sand, gravel extraction | Large-scale metal ore mining like copper and gold |

Introduction to Surface Mining and Block Caving

Surface mining involves the removal of large areas of soil and rock to access mineral deposits near the earth's surface, making it ideal for extracting shallow ore bodies such as coal, copper, and iron. Block caving is an underground mining method that exploits the natural fragmentation of ore by undercutting and causing controlled collapse, suited for deep, massive ore bodies like copper and gold. Both techniques optimize resource recovery and operational efficiency by targeting different ore deposit geometries and depths.

Key Differences Between Surface Mining and Block Caving

Surface mining involves extracting minerals from an open pit or borrow, characterized by large-scale removal of overburden and direct access to ore deposits near the surface. Block caving is an underground mining method that involves undermining an ore body, causing it to collapse and be collected at draw points, ideal for low-grade, massive ore deposits. Key differences include surface mining's higher environmental impact and easier ore access versus block caving's lower surface disturbance and suitability for deep ore bodies with significant initial infrastructure investment.

Geology Suitability: Surface vs Block Caving

Surface mining is most suitable for shallow, horizontally extensive ore bodies with relatively uniform geology, allowing efficient removal of overburden and direct access to the ore. Block caving is ideal for deep, massive, and steeply dipping ore bodies with competent rock that can cave effectively under gravity, minimizing extraction costs in complex geology. Geology suitability depends heavily on ore depth, rock strength, and deposit geometry, guiding the selection between surface mining and block caving methods.

Extraction Techniques: Processes Compared

Surface mining involves the removal of overburden to access ore deposits near the earth's surface, utilizing techniques such as open-pit, strip, and mountaintop mining for efficient large-scale extraction. Block caving, a subsurface mining method, relies on controlled collapse of ore bodies to extract minerals from deep underground, offering high production rates with reduced waste rock handling. The choice between surface mining and block caving depends on ore depth, geology, and economic factors, with block caving favored for massive, low-grade deposits and surface mining optimal for shallower, high-grade ores.

Equipment Used in Surface Mining vs Block Caving

Surface mining employs large-scale equipment such as draglines, power shovels, bulldozers, and haul trucks designed for extracting minerals from an open pit. Block caving relies on underground machinery including loaders, conveyor systems, and crushers to handle fragmented ore falling from the caved orebody. The choice of equipment directly influences operational efficiency and cost-effectiveness in these mining methods.

Production Rates and Efficiency

Surface mining achieves higher production rates compared to block caving, extracting large volumes of ore rapidly due to open-pit methods. Block caving, though slower, offers superior efficiency in recovering ore from deep underground deposits with lower operating costs and reduced waste. Mining companies balance these factors by selecting surface mining for shallow, high-grade deposits and block caving for large, low-grade orebodies at depth.

Cost Analysis: Capital and Operational Expenditures

Surface mining typically demands higher initial capital expenditures due to extensive equipment and site preparation but benefits from lower operational costs per ton extracted, enhancing cost efficiency over large deposits. Block caving involves significant upfront investment in underground infrastructure, including shaft sinking and cave development, resulting in higher operational expenses linked to ventilation, ground control, and specialized labor. Cost analysis must weigh surface mining's scalability and simpler logistics against block caving's potential for lower extraction costs in deep ore bodies, emphasizing project-specific geological and economic factors.

Environmental Impact and Rehabilitation

Surface mining often results in significant land disturbance, habitat destruction, and increased erosion, leading to prolonged environmental degradation, whereas block caving has a smaller surface footprint but can cause subsidence and groundwater disruption. Rehabilitation of surface mines demands extensive soil replacement, re-vegetation, and landscape contouring to restore ecosystems, while block caving areas require monitoring and mitigation of subsidence effects to stabilize the land and protect water resources. Effective environmental management strategies for both methods involve rigorous site assessment, continuous monitoring, and tailored rehabilitation plans to minimize long-term ecological damage.

Safety Considerations and Risk Management

Surface mining offers enhanced safety due to open-air operations and easier emergency access, reducing risks of cave-ins and hazardous gas exposure. Block caving involves underground excavation with higher risk of rock falls, ground subsidence, and ventilation challenges, necessitating rigorous monitoring and advanced risk management systems. Implementing real-time geotechnical sensors and comprehensive safety protocols is critical to mitigate risks specific to each mining method.

Future Trends in Surface Mining and Block Caving Techniques

Surface mining advancements focus on integrating autonomous equipment and real-time data analytics to enhance operational efficiency and environmental sustainability. Block caving techniques are evolving with improved cave control technologies and seismic monitoring systems, reducing risks and increasing ore recovery rates. Future trends emphasize digital twin models and machine learning algorithms to optimize mine planning and resource extraction.

Related Important Terms

In-pit crushing and conveying (IPCC)

In-pit crushing and conveying (IPCC) systems significantly enhance efficiency in surface mining by reducing truck haulage and lowering fuel consumption compared to traditional block caving methods, which rely heavily on underground haul trucks. IPCC integrates crushers within the pit, enabling continuous material movement and minimizing operational costs, making it an optimal choice for large-scale surface mining operations.

Hydraulic mining shovels

Hydraulic mining shovels in surface mining offer high efficiency and flexibility for excavating large volumes of overburden, contrasting with block caving's underground approach that leverages gravity to extract ore with lower surface disturbance. These shovels enhance productivity by rapidly loading materials onto trucks, making surface mining suitable for shallower deposits, whereas block caving excels in deep, massive ore bodies.

Autonomous haulage system (AHS)

Autonomous Haulage Systems (AHS) enhance operational efficiency and safety in surface mining by enabling continuous, remote-controlled truck operations over large open-pit areas, reducing reliance on manual labor and lowering operational costs. In contrast, block caving, an underground mining method, poses challenges for AHS integration due to confined tunnels and complex underground logistics, limiting autonomous vehicle deployment primarily to surface transport links rather than within the cave itself.

Sub-level caving optimization

Sub-level caving optimizes ore extraction by enhancing fragmentation and minimizing dilution compared to traditional surface mining, allowing efficient recovery of large, low-grade ore bodies through controlled cave propagation. This method reduces operational costs and environmental impacts by maximizing ore throughput while maintaining ground stability in block caving operations.

Panel caving sequencing

Panel caving sequencing in surface mining involves systematically removing ore panels to maintain stability and optimize extraction efficiency, while block caving relies on controlled subsidence to fragment underground ore bodies for continuous flow. Compared to block caving, panel caving requires precise planning of cutback sequences to prevent premature collapse and maximize ore recovery in large-scale open-pit operations.

Preconditioning (hydraulic fracturing for caving)

Surface mining relies on removing overburden to expose ore, while block caving employs preconditioning techniques such as hydraulic fracturing to induce controlled rock fragmentation and facilitate cave propagation. Hydraulic fracturing in block caving enhances permeability and weakens rock integrity, optimizing extraction efficiency and safety in underground mining operations.

Ore flow dilutions

Surface mining typically experiences lower ore flow dilution due to the selective excavation of ore bodies, whereas block caving involves higher dilution rates as fragmented ore and waste rock mix during underground collapse. Efficient ore flow management in block caving requires advanced control measures to minimize dilution and maximize ore recovery compared to surface mining methods.

Near-surface cave initiation

Surface mining efficiently extracts near-surface mineral deposits with minimal overburden removal, while block caving initiates near-surface cave breaks through controlled undermining, enabling large-scale ore mass collapse for deeper resources. Near-surface cave initiation in block caving enhances fragmentation and ore recovery by exploiting stress redistribution at shallow depths compared to traditional surface mining methods.

Highwall stability monitoring

Highwall stability monitoring in surface mining employs real-time geotechnical sensors and remote sensing technologies to detect early signs of slope failure, ensuring worker safety and operational efficiency. In block caving, subsidence monitoring and microseismic data integration are critical for tracking ground deformation and optimizing cave propagation, minimizing environmental impact.

Digital mine twin (simulation for mine planning)

Digital mine twins enhance surface mining by enabling precise simulation of terrain changes and equipment operations, optimizing haul routes and pit design for effective resource extraction. In block caving, digital twins simulate subsidence effects and cave propagation, improving stability monitoring and production forecasting for safer, cost-efficient underground mining.

Surface mining vs Block caving Infographic

industrydif.com

industrydif.com