Heap leaching and microbial mining are both hydrometallurgical processes used to extract valuable metals from low-grade ores. Heap leaching involves stacking crushed ore and applying chemical solutions to dissolve target metals, while microbial mining employs bacteria to bio-oxidize minerals, enhancing metal recovery through natural biochemical reactions. Each method offers distinct advantages in cost-efficiency, environmental impact, and suitability based on ore type and mineralogy.

Table of Comparison

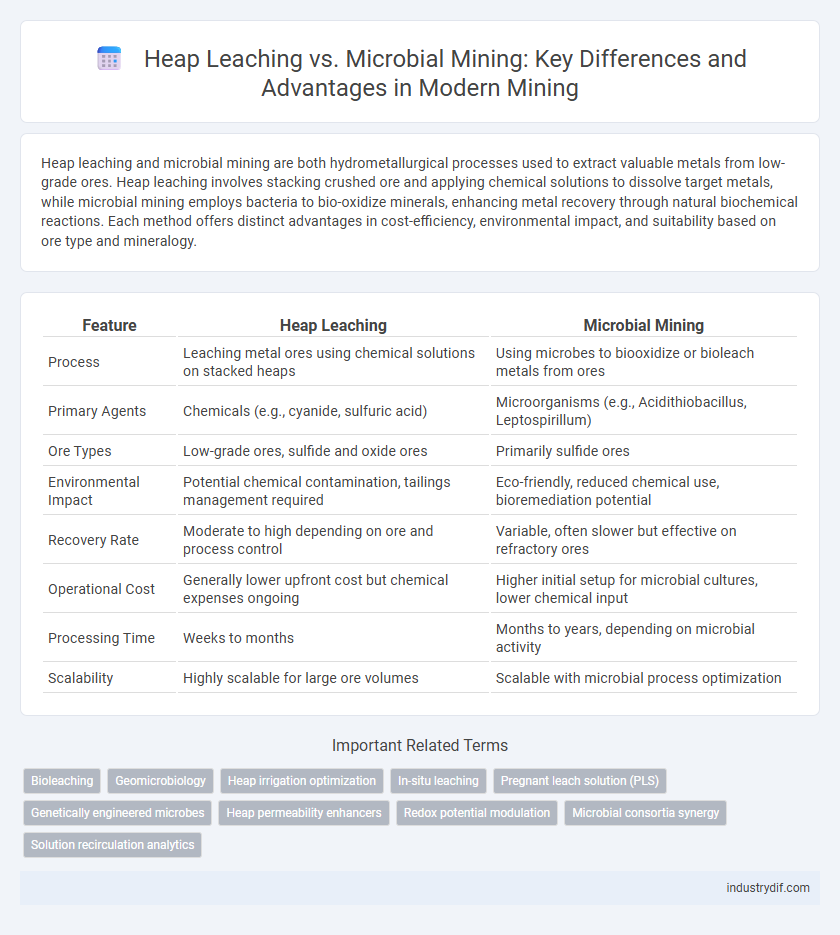

| Feature | Heap Leaching | Microbial Mining |

|---|---|---|

| Process | Leaching metal ores using chemical solutions on stacked heaps | Using microbes to biooxidize or bioleach metals from ores |

| Primary Agents | Chemicals (e.g., cyanide, sulfuric acid) | Microorganisms (e.g., Acidithiobacillus, Leptospirillum) |

| Ore Types | Low-grade ores, sulfide and oxide ores | Primarily sulfide ores |

| Environmental Impact | Potential chemical contamination, tailings management required | Eco-friendly, reduced chemical use, bioremediation potential |

| Recovery Rate | Moderate to high depending on ore and process control | Variable, often slower but effective on refractory ores |

| Operational Cost | Generally lower upfront cost but chemical expenses ongoing | Higher initial setup for microbial cultures, lower chemical input |

| Processing Time | Weeks to months | Months to years, depending on microbial activity |

| Scalability | Highly scalable for large ore volumes | Scalable with microbial process optimization |

Overview of Heap Leaching and Microbial Mining

Heap leaching is a hydrometallurgical process that involves stacking crushed ore in large heaps and applying a leaching solution to extract valuable metals, such as gold, copper, and uranium, through percolation. Microbial mining, or bioleaching, utilizes specific bacteria and microorganisms to biologically oxidize and solubilize metals from sulfide ores, enhancing metal recovery in an eco-friendly manner. Both techniques offer cost-effective alternatives to traditional methods, with heap leaching suitable for low-grade ores and microbial mining providing sustainable metal extraction by leveraging microbial metabolism.

Fundamental Principles of Heap Leaching

Heap leaching involves stacking crushed ore into heaps and applying a leaching solution that percolates through the material to dissolve target metals like gold or copper. This method relies on the principles of chemical extraction through solvent permeability and metal solubility, allowing efficient recovery over extended periods. The process optimizes metal recovery by controlling parameters such as heap permeability, solution application rate, and pH levels.

Key Mechanisms in Microbial Mining

Microbial mining leverages specific microorganisms to oxidize sulfide minerals, facilitating metal solubilization through biochemical reactions that break down mineral matrices. Key mechanisms include bioleaching by acidophilic bacteria such as Acidithiobacillus ferrooxidans, which oxidize ferrous iron and sulfur compounds, generating sulfuric acid and ferric ions that enhance metal extraction. This biologically-driven process contrasts with heap leaching by providing increased metal recovery rates and environmental benefits due to lower chemical reagent use.

Comparative Process Flow: Heap Leaching vs Microbial Mining

Heap leaching involves stacking ore on a prepared pad and percolating a leach solution to dissolve valuable metals, while microbial mining uses microorganisms to biooxidize and solubilize metals from ores. The heap leaching process is typically faster but relies heavily on chemical reagents, whereas microbial mining offers a more environmentally friendly approach by harnessing biological activity over extended periods. Key parameters such as ore type, metal recovery rates, and environmental impact determine the optimal process selection between heap leaching and microbial mining.

Ore Types Suitable for Each Method

Heap leaching is most effective for low-grade, oxide ores such as gold and copper, where the metals are soluble in the leaching agents used. Microbial mining, or bioleaching, is suitable for sulfide ores, including chalcopyrite and pyrite, as specific microorganisms facilitate metal extraction by oxidizing sulfide minerals. Selecting the appropriate method depends on ore mineralogy, with heap leaching favored for oxide ores and microbial mining optimized for refractory sulfide concentrates.

Environmental Impacts and Sustainability Considerations

Heap leaching involves the use of chemical solutions, primarily cyanide or sulfuric acid, which can lead to soil and water contamination if not managed properly, posing significant environmental risks. Microbial mining utilizes naturally occurring microorganisms to bioleach metals, offering a more sustainable alternative by reducing harmful chemical usage and minimizing toxic waste generation. The sustainability of microbial mining is enhanced by its lower energy consumption and biodegradability, making it a preferable choice for eco-friendly mineral extraction.

Metal Recovery Efficiency: Heap Leaching vs Microbial Mining

Heap leaching achieves metal recovery efficiencies typically ranging from 60% to 80% for metals like gold and copper, leveraging chemical solutions to dissolve metals from ore heaps. Microbial mining, or bioleaching, enhances recovery rates by utilizing microorganisms to biologically oxidize sulfide minerals, often increasing metal recovery efficiency by 10% to 20% compared to conventional heap leaching. The biological processes in microbial mining enable higher extraction rates in low-grade ores and complex sulfide minerals, improving overall metal yield and environmental sustainability.

Operational Costs and Economic Viability

Heap leaching involves low operational costs due to simple infrastructure and minimal energy inputs, making it economically viable for low-grade ores. Microbial mining, while potentially offering higher recovery rates and eco-friendly benefits, incurs higher operational costs from maintaining microbial cultures and longer processing times. Economic viability depends on ore grade, scale, and environmental regulations, with heap leaching favored in large-scale, low-cost operations and microbial mining suitable for niche applications.

Technological Advancements and Innovations

Heap leaching leverages advancements in chemical reagents and automated irrigation systems to enhance metal recovery from low-grade ores efficiently. Microbial mining employs genetically engineered microorganisms and bioinformatics tools to optimize the biooxidation and bioleaching processes, increasing extraction rates while minimizing environmental impact. Integration of sensor technology and process modeling in both methods drives innovation, improving monitoring, control, and scalability in modern mining operations.

Future Trends in Leaching Technologies

Future trends in leaching technologies emphasize the integration of microbial mining with heap leaching to enhance metal recovery efficiency and environmental sustainability. Advances in biotechnology enable the development of tailored microbial consortia that accelerate the biooxidation process in heap leaching operations, reducing processing time and operational costs. Innovations in sensor technology and process automation further optimize leaching parameters, leading to improved resource utilization and minimized environmental impact.

Related Important Terms

Bioleaching

Heap leaching utilizes chemical solutions to extract metals from ore by percolating fluids through stacked ore heaps, while bioleaching employs microorganisms to oxidize and solubilize metals, making it an eco-friendly alternative in mining. Bioleaching, particularly effective for copper and gold extraction, reduces environmental impact and operational costs compared to traditional heap leaching methods.

Geomicrobiology

Heap leaching utilizes chemical agents to extract metals from ore piled in heaps, whereas microbial mining leverages geomicrobiology by employing microorganisms to bioleach metals through biochemical reactions. Geomicrobiology enhances microbial mining efficiency by exploiting bacteria and archaea that metabolize minerals, accelerating metal recovery while reducing environmental impact compared to traditional heap leaching.

Heap irrigation optimization

Heap irrigation optimization enhances metal recovery by improving solution distribution and oxygen flow in heap leaching, increasing efficiency in extracting valuable minerals from low-grade ores. In contrast, microbial mining utilizes bacteria to bio-oxidize ores, but its integration with optimized heap irrigation techniques can further accelerate leaching rates and metal yield.

In-situ leaching

In-situ leaching, a subset of heap leaching, involves injecting lixiviants directly into ore deposits underground, enabling metal extraction without traditional excavation, thus minimizing surface disturbance and environmental impact. Microbial mining employs bioengineered microbes to enhance metal recovery by oxidizing sulfide minerals in-situ, offering a sustainable alternative with higher selectivity and reduced chemical use compared to conventional heap leaching methods.

Pregnant leach solution (PLS)

Pregnant Leach Solution (PLS) in heap leaching contains dissolved metals extracted from ore by chemical solutions, while in microbial mining, PLS results from bio-oxidation processes where microorganisms enhance metal solubilization. The PLS from microbial mining often exhibits higher metal concentrations and lower impurity levels compared to traditional heap leaching, improving subsequent metal recovery stages.

Genetically engineered microbes

Genetically engineered microbes used in microbial mining enhance metal recovery rates and reduce environmental impact by tailoring metabolic pathways for specific ore compositions, outperforming traditional heap leaching methods that rely on natural microbial activity and slower chemical reactions. These engineered organisms facilitate efficient extraction of metals such as copper and gold through bio-oxidation and bioleaching processes, offering a sustainable alternative with improved selectivity and process control compared to heap leaching's passive and extended timeframe.

Heap permeability enhancers

Heap leaching efficiency is significantly improved by permeability enhancers such as coarse ore fragmentation and bioleaching agents that promote fluid flow, whereas microbial mining leverages specific microorganisms to both break down sulfide minerals and enhance heap permeability through biofilm formation and acid production. Integrating permeability enhancers in heap leaching optimizes metal recovery by maintaining uniform solution distribution, contrasting with microbial mining's targeted biocatalytic mechanisms that simultaneously improve permeability and mineral dissolution rates.

Redox potential modulation

Heap leaching relies on chemical oxidation to enhance metal recovery by increasing redox potential through the addition of oxidizing agents like ferric iron, while microbial mining utilizes redox-active microorganisms that modulate redox potential biologically, promoting in situ mineral dissolution. This biological modulation of redox potential in microbial mining often results in more sustainable and efficient extraction of metals compared to the conventional heap leaching process.

Microbial consortia synergy

Microbial mining leverages the synergistic interactions within microbial consortia to enhance metal bioleaching efficiency, outperforming traditional heap leaching by accelerating mineral dissolution and reducing environmental impact. The cooperative metabolism of diverse microbes optimizes biooxidation processes, enabling extraction from low-grade ores that heap leaching struggles to process effectively.

Solution recirculation analytics

Heap leaching employs solution recirculation analytics to optimize metal recovery by continuously monitoring pH, temperature, and contaminant levels in the leachate, ensuring maximal extraction efficiency. Microbial mining integrates bioinformatics-driven recirculation analytics to track microbial activity and nutrient cycling dynamically, enhancing bio-oxidation rates and minimizing environmental impact.

Heap leaching vs Microbial mining Infographic

industrydif.com

industrydif.com