Room and pillar mining involves excavating a series of rooms while leaving pillars of untouched material to support the roof, providing stability and reducing surface subsidence. Block caving is an underground mining method where large sections of ore bodies are undercut, causing them to collapse under their own weight, allowing gravity to assist in ore extraction. Room and pillar is typically used for flat-lying deposits with strong rock, whereas block caving is more efficient for massive, steeply dipping ore bodies with lower rock strength.

Table of Comparison

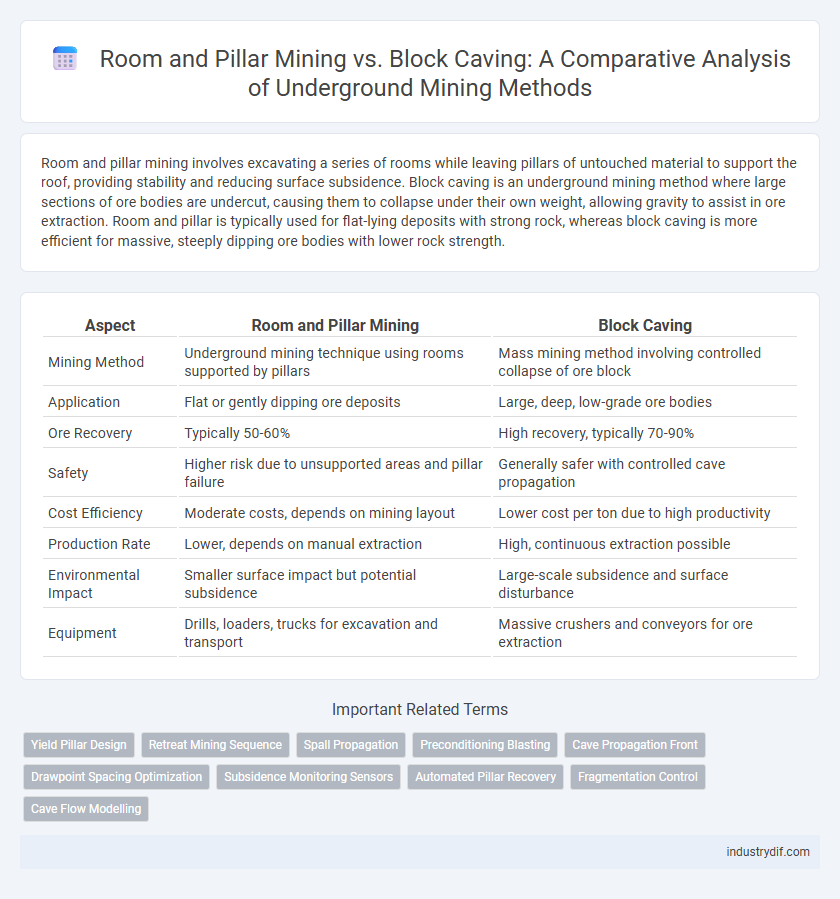

| Aspect | Room and Pillar Mining | Block Caving |

|---|---|---|

| Mining Method | Underground mining technique using rooms supported by pillars | Mass mining method involving controlled collapse of ore block |

| Application | Flat or gently dipping ore deposits | Large, deep, low-grade ore bodies |

| Ore Recovery | Typically 50-60% | High recovery, typically 70-90% |

| Safety | Higher risk due to unsupported areas and pillar failure | Generally safer with controlled cave propagation |

| Cost Efficiency | Moderate costs, depends on mining layout | Lower cost per ton due to high productivity |

| Production Rate | Lower, depends on manual extraction | High, continuous extraction possible |

| Environmental Impact | Smaller surface impact but potential subsidence | Large-scale subsidence and surface disturbance |

| Equipment | Drills, loaders, trucks for excavation and transport | Massive crushers and conveyors for ore extraction |

Introduction to Room and Pillar Mining and Block Caving

Room and pillar mining involves excavating rooms in a mineral seam while leaving pillars of ore to support the roof, commonly used in flat-lying deposits such as coal and potash. Block caving is an underground mass mining method where the ore body is undercut, causing it to fracture and cave under its own weight, ideal for large, low-grade porphyry copper and diamond deposits. Both methods balance ore recovery and ground control, with room and pillar offering selective extraction and block caving providing high production rates for bulk ores.

Basic Principles of Room and Pillar Mining

Room and pillar mining involves excavating horizontal passages or "rooms" while leaving pillars of unmined material to support the roof, ensuring stability throughout extraction. This method is commonly used for flat-lying ore bodies with uniform thickness, facilitating ventilation and easy access for machinery. Pillar size and spacing are carefully designed based on rock strength and overburden conditions to prevent collapse and optimize ore recovery.

Fundamental Concepts of Block Caving

Block caving is an underground mining method characterized by the intentional fracturing and controlled collapse of a large ore body, allowing ore to be recovered by gravity through drawpoints located beneath the caved zone. Unlike room and pillar mining, which leaves pillars of ore to support the roof, block caving relies on the natural fragmentation of the rock mass, enabling extraction of large volumes of low-grade ore with high productivity and lower operational costs. Key elements include undercutting, caving propagation, and draw control, making it efficient for mining massive, moderately to highly fractured ore bodies at great depths.

Geological Suitability and Ore Types

Room and pillar mining is best suited for flat-lying, moderately thick ore bodies with competent rock that can support pillars, commonly applied to coal, salt, and potash deposits. Block caving excels in large, low-grade, and massive ore bodies with weak and fractured rock, such as copper and gold porphyry deposits, where gravity-induced collapse facilitates ore extraction. Geological suitability is critical, as room and pillar requires stable conditions to maintain roof integrity, whereas block caving depends on controlled ground subsidence for efficient ore recovery.

Equipment and Technology Requirements

Room and pillar mining requires versatile equipment such as continuous miners, shuttle cars, and roof bolters to efficiently extract and support the mine structure, emphasizing mobility and safety technologies. Block caving demands heavy-duty, large-scale machinery including crushers, conveyors, and drawbells, alongside advanced automation systems to manage the controlled collapse and material flow from the caved ore body. The technology in room and pillar mining prioritizes ground control and ventilation, whereas block caving focuses on high-capacity material handling and monitoring systems for cave propagation.

Production Rates and Efficiency Comparison

Room and pillar mining typically achieves moderate production rates with efficient ore recovery in flat and stable geological conditions, allowing selective extraction and minimal dilution. Block caving offers significantly higher production rates due to large-scale, gravity-driven extraction but may face lower ore recovery efficiency because of dilution and caving control challenges. In terms of operational efficiency, room and pillar ensures safer ground control and simpler ventilation, while block caving maximizes throughput for massive, low-grade ore bodies, optimizing overall productivity despite higher initial capital costs.

Safety Considerations and Ground Stability

Room and pillar mining offers enhanced ground stability by leaving pillars that support the roof, significantly reducing collapse risk and improving safety for miners working in underground mines. In contrast, block caving involves controlled collapse of large ore bodies, which requires extensive monitoring to manage ground subsidence and mitigate hazards associated with falling rock and ground movement. Safety considerations in block caving necessitate advanced ground control systems and evacuation protocols to ensure worker protection during the caving process.

Environmental Impact and Footprint

Room and pillar mining typically results in less surface subsidence and a smaller environmental footprint due to its selective extraction and support pillars that maintain ground stability. Block caving, while allowing for higher resource recovery and lower operational costs, causes significant ground subsidence and larger surface disturbance, leading to more profound ecological impacts. The choice between these methods hinges on balancing resource efficiency with minimizing habitat disruption and land degradation.

Cost Analysis and Economic Viability

Room and pillar mining typically involves lower upfront capital expenditure but higher operating costs due to continuous roof support and ore extraction limitations. Block caving offers greater economies of scale with lower operational costs per ton of ore, making it economically viable for large, low-grade ore bodies despite its significant initial investment and longer development time. Cost analysis favors room and pillar mining for smaller, shallow deposits, whereas block caving is more cost-effective for deep, extensive ore bodies with higher throughput requirements.

Selection Criteria for Mining Methods

Selection criteria for mining methods like room and pillar versus block caving depend primarily on orebody geometry, depth, and rock stability. Room and pillar mining suits shallow deposits with flat-lying ore and stable rock, enabling selective extraction and minimal surface subsidence. In contrast, block caving is optimal for large, deep, and massive orebodies with weaker rock, offering high production rates but requiring significant upfront capital and ground control measures.

Related Important Terms

Yield Pillar Design

Room and pillar mining relies on strategically designed yield pillars to maintain mine stability while maximizing ore extraction, balancing pillar size and extraction ratio to optimize ground support and minimize dilution. Block caving undermines ore bodies causing controlled collapse, offering higher extraction rates but requiring less emphasis on individual pillar design due to bulk mining methods.

Retreat Mining Sequence

Room and pillar mining employs a retreat mining sequence where miners systematically extract ore by removing pillars to collapse mined-out areas, ensuring controlled subsidence and safety. Block caving uses a top-down retreat mining sequence that exploits gravity-driven fragmentation, allowing large-scale extraction by undercutting ore bodies for efficient ore flow and lower operational costs.

Spall Propagation

Room and pillar mining involves creating a grid of rooms supported by pillars to maintain stability, minimizing spall propagation by controlling stress distribution within the pillars. Block caving, by contrast, induces large-scale fracturing and spall propagation through intentional collapse of ore bodies, enabling extraction but increasing the risk of rock fragmentation and ground subsidence.

Preconditioning Blasting

Preconditioning blasting in room and pillar mining involves controlled explosive applications to reduce rock strength around pillars, enhancing stability and safety, whereas block caving employs extensive preconditioning to fracture ore mass and promote cave-in for efficient, large-scale extraction. The effectiveness of preconditioning blasting directly impacts ore recovery rates, ground control, and operational costs in both mining methods.

Cave Propagation Front

Room and pillar mining maintains high stability by leaving pillars untouched, preventing extensive cave propagation fronts, while block caving induces a controlled cave propagation front that systematically undermines the ore body for mass extraction. The advancement of the cave propagation front in block caving directly impacts subsidence and ore recovery, contrasting with the localized stability preserved in room and pillar methods.

Drawpoint Spacing Optimization

Optimizing drawpoint spacing in room and pillar mining enhances ore recovery and ventilation while minimizing dilution compared to block caving, where larger drawpoint intervals support subsidence control and mass ore flow management. Precise drawpoint spacing in block caving enables efficient ore fragmentation and extraction but requires extensive geotechnical analysis to balance cave stability and production rates.

Subsidence Monitoring Sensors

Room and pillar mining utilizes subsidence monitoring sensors to detect surface deformation by measuring vertical displacement and stress changes above the mined-out areas, ensuring structural stability through real-time data. In contrast, block caving mining employs advanced geotechnical sensors to monitor large-scale ground subsidence and cave propagation, providing critical insights for managing ground control and preventing hazardous collapse.

Automated Pillar Recovery

Automated pillar recovery in room and pillar mining enhances safety and efficiency by using robotics and remote-controlled equipment to extract pillars, minimizing human exposure to hazardous conditions. In contrast, block caving relies on gravity-induced collapse of ore bodies, offering large-scale production but with less control over selective extraction compared to automated pillar recovery techniques.

Fragmentation Control

Room and pillar mining enables precise fragmentation control by maintaining strategic pillar placement to support overburden, resulting in minimal rock breakage variability and controlled ore recovery. Block caving relies on natural rock fragmentation through gravity-induced collapse, offering less direct control over fragmentation size but enabling large-scale ore extraction with efficient cave propagation management.

Cave Flow Modelling

Room and pillar mining involves leaving columns of ore to support the roof, whereas block caving exploits the natural fracturing and gravitational flow of ore through caving techniques. Cave flow modelling in block caving simulates ore fragmentation and granular flow to optimize draw control and improve extraction efficiency compared to the static stability approach in room and pillar mining.

Room and pillar mining vs Block caving Infographic

industrydif.com

industrydif.com