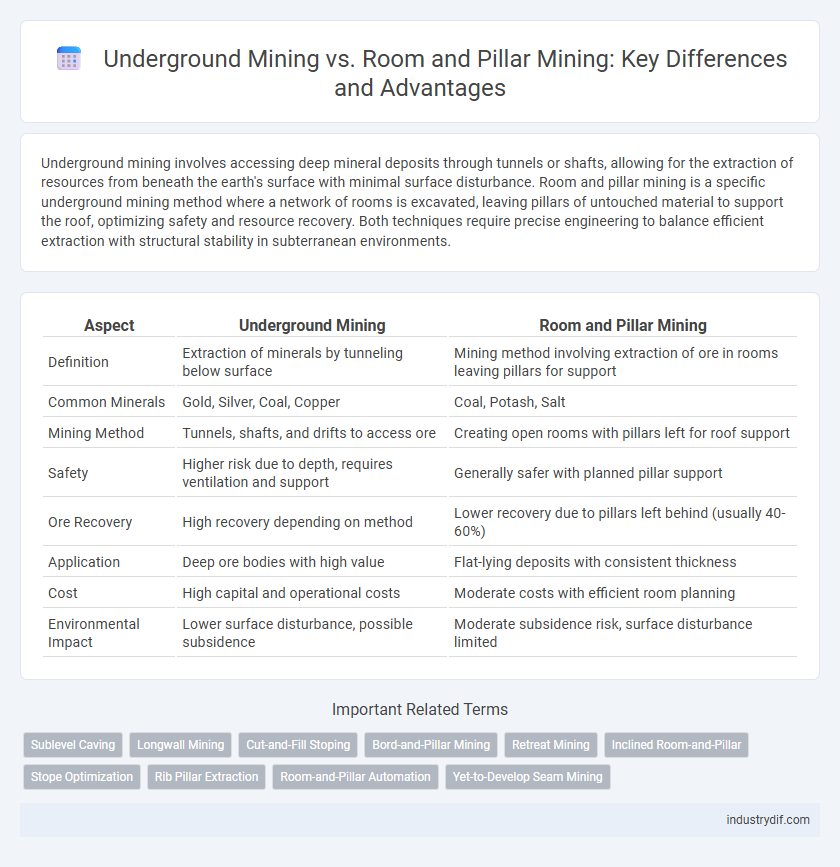

Underground mining involves accessing deep mineral deposits through tunnels or shafts, allowing for the extraction of resources from beneath the earth's surface with minimal surface disturbance. Room and pillar mining is a specific underground mining method where a network of rooms is excavated, leaving pillars of untouched material to support the roof, optimizing safety and resource recovery. Both techniques require precise engineering to balance efficient extraction with structural stability in subterranean environments.

Table of Comparison

| Aspect | Underground Mining | Room and Pillar Mining |

|---|---|---|

| Definition | Extraction of minerals by tunneling below surface | Mining method involving extraction of ore in rooms leaving pillars for support |

| Common Minerals | Gold, Silver, Coal, Copper | Coal, Potash, Salt |

| Mining Method | Tunnels, shafts, and drifts to access ore | Creating open rooms with pillars left for roof support |

| Safety | Higher risk due to depth, requires ventilation and support | Generally safer with planned pillar support |

| Ore Recovery | High recovery depending on method | Lower recovery due to pillars left behind (usually 40-60%) |

| Application | Deep ore bodies with high value | Flat-lying deposits with consistent thickness |

| Cost | High capital and operational costs | Moderate costs with efficient room planning |

| Environmental Impact | Lower surface disturbance, possible subsidence | Moderate subsidence risk, surface disturbance limited |

Overview of Underground Mining Methods

Underground mining encompasses various methods such as room and pillar, cut and fill, and block caving, each tailored to deposit geometry and rock conditions. Room and pillar mining specifically involves excavating rooms while leaving pillars of ore to support the roof, making it suitable for flat-lying, tabular ore bodies. Variations in ground stability, ore visibility, and ventilation requirements influence the selection between room and pillar and other underground mining techniques.

Introduction to Room and Pillar Mining

Room and pillar mining is a widely used underground mining method where rooms are excavated while pillars of unmined material support the roof, ensuring stability. This technique is especially effective in flat or gently dipping deposits, providing efficient ore extraction with minimal ground subsidence. Its adaptability to various coal seams and metal ores makes it a preferred choice for safe and productivity-focused underground mining operations.

Key Differences Between Underground Mining and Room and Pillar Mining

Underground mining involves excavating deep tunnels to access ore deposits, often using methods like longwall or cut-and-fill mining, while room and pillar mining specifically entails creating a network of rooms separated by pillars of coal or rock left to support the roof. Key differences include the structural approach, as room and pillar mining maintains stability through these pillars, whereas underground mining may employ extensive ground support systems and more varied excavation techniques. Additionally, room and pillar mining is typically used for flat-lying ore seams with less depth, whereas underground mining can target deeper and more complex ore bodies.

Geological Conditions Suitable for Each Method

Underground mining is most effective in deep ore bodies where vertical space is constrained, typically in hard rock formations with stable geology to support tunnel stability. Room and pillar mining suits flat-lying, tabular deposits in relatively shallow depths with competent rock masses that can maintain the pillars without collapsing. Geological conditions such as rock strength, depth, and ore body shape critically influence the choice between these mining methods to optimize safety and extraction efficiency.

Equipment Used in Underground vs Room and Pillar Mining

Underground mining utilizes specialized equipment such as continuous miners, longwall shearers, and shuttle cars designed for deep and confined spaces, whereas room and pillar mining primarily employs equipment like scoop trams, roof bolters, and chain conveyors to manage the extraction of resources while supporting the mine roof. Continuous miners in underground mining enable efficient cutting and loading, while roof bolters in room and pillar mining stabilize the pillars and tunnels, ensuring safety during extraction. The distinction in machinery reflects the operational requirements, with underground mining equipment focusing on continuous extraction in complex geologies, and room and pillar mining equipment optimized for selective mining and structural integrity.

Advantages and Disadvantages of Underground Mining

Underground mining offers access to deeper ore bodies with minimal surface disruption, providing higher recovery rates for valuable minerals compared to room and pillar mining. It allows for selective extraction and reduced environmental footprint, but presents challenges including higher operational costs, increased safety risks, and ventilation requirements. Despite these disadvantages, underground mining is essential for exploiting deposits that are not economically viable with surface methods.

Pros and Cons of Room and Pillar Mining

Room and pillar mining offers the advantage of providing excellent ground stability by leaving pillars of untouched material to support the roof, reducing the risk of collapses and ensuring miner safety. This method allows for selective extraction with minimal surface subsidence, preserving the environment above the mine. However, room and pillar mining often results in lower recovery rates compared to other techniques, as a significant portion of the resource remains locked within the pillars, leading to potential economic inefficiencies.

Safety Considerations in Mining Methods

Underground mining poses significant safety risks due to deep excavation and potential for tunnel collapses, requiring robust ventilation and ground support systems. Room and pillar mining enhances safety by leaving substantial coal or ore pillars to support the roof, reducing the likelihood of cave-ins during extraction. Effective risk management in both methods depends on continuous monitoring of structural integrity and implementation of advanced safety protocols.

Economic Factors in Method Selection

Underground mining often requires higher initial capital investment and operational costs due to extensive infrastructure like shafts and ventilation systems, while room and pillar mining offers lower upfront expenses and faster development. Economic factors such as ore grade, deposit geometry, and market prices heavily influence method selection, with room and pillar favored for shallow, tabular deposits to maximize recovery at minimal cost. Long-term profitability depends on balancing extraction efficiency against safety, ventilation, and ground control expenses inherent in each mining technique.

Environmental Impact Comparison

Underground mining typically results in less surface disturbance compared to room and pillar mining, which can cause significant land subsidence due to the removal of large coal pillars. Room and pillar methods often leave behind a large portion of the resource, reducing waste but increasing the volume of disturbed underground spaces that may alter groundwater flow and cause contamination. Both methods pose challenges to ecosystem stability, but underground mining generally has a lower footprint on surface vegetation and soil.

Related Important Terms

Sublevel Caving

Sublevel caving is an underground mining method that involves controlled collapse of ore below sublevels, maximizing ore recovery and minimizing dilution compared to room and pillar mining, which leaves pillars of ore to support the roof but results in lower extraction rates. Sublevel caving offers greater safety and efficiency in massive, low-grade ore bodies by allowing continuous extraction and automated mucking systems.

Longwall Mining

Longwall mining uses a mechanized shearer moving along a coal face for high productivity and safety, contrasting with room and pillar mining where coal pillars support the roof. This method enables efficient extraction of large coal blocks and controlled roof collapse, minimizing surface subsidence and operational hazards.

Cut-and-Fill Stoping

Cut-and-fill stoping in underground mining offers precise ore extraction by sequentially excavating horizontal slices and backfilling voids, enhancing ground support compared to room and pillar methods which leave pillars to support the roof. This technique optimizes ore recovery in irregular or steeply dipping ore bodies, minimizing dilution and improving safety in complex underground geologies.

Bord-and-Pillar Mining

Bord-and-pillar mining is a common form of underground mining where a grid of pillars is left to support the roof while extracting the surrounding ore, providing enhanced stability compared to traditional room and pillar methods. This technique allows for efficient resource recovery in flat-lying deposits, minimizing ground subsidence and improving worker safety.

Retreat Mining

Retreat mining, a phase within room and pillar mining, involves systematically removing pillars left during the initial advancing phase, allowing controlled subsidence and maximizing resource recovery. This method contrasts with traditional underground mining techniques by prioritizing safety and operational efficiency through phased extraction and strategic support removal.

Inclined Room-and-Pillar

Inclined room-and-pillar mining, a variant of traditional underground mining, features sloped rooms and pillars designed to follow ore bodies with dip angles, enhancing ore recovery and stability in inclined deposits. This method improves ventilation and reduces ground control challenges compared to conventional horizontal room-and-pillar techniques commonly used in flat-lying mineral seams.

Stope Optimization

Underground mining utilizes stope optimization techniques to maximize ore recovery and enhance safety by precisely designing stope dimensions and sequencing, while room and pillar mining relies on optimizing pillar size and extractor layout to maintain structural stability and extraction efficiency. Advanced software integrates geological, geotechnical, and economic data for both methods, enabling tailored stope or pillar configurations that increase productivity and reduce dilution.

Rib Pillar Extraction

Rib pillar extraction in underground mining involves the careful removal of rock pillars that support mine roofs, which distinguishes it from traditional room and pillar mining where pillars are generally left intact for safety. Advances in rib pillar extraction techniques enhance resource recovery by safely extracting these pillars while maintaining structural stability, optimizing ore extraction efficiency.

Room-and-Pillar Automation

Room-and-pillar mining automation enhances operational safety and efficiency by utilizing autonomous machinery for drilling, loading, and hauling within the underground grid of pillars and rooms. Compared to traditional underground mining methods, automated systems in room-and-pillar mining reduce human exposure to hazardous conditions while optimizing resource extraction through precise, real-time monitoring and control.

Yet-to-Develop Seam Mining

Yet-to-develop seam mining in underground mining offers access to deeper ore bodies beyond the limits of existing room and pillar operations, maximizing resource extraction while maintaining ground stability. Advanced techniques like continuous miners and pillar recovery enhance safety and efficiency, making it a preferred method for exploiting seams with complex geology or varying thickness.

Underground mining vs Room and pillar mining Infographic

industrydif.com

industrydif.com