Pallet racking provides a static storage solution that maximizes vertical space and supports heavy loads, making it ideal for long-term inventory storage. Dynamic slotting optimizes warehouse efficiency by constantly adjusting product locations based on demand and turnover rates, reducing picking time and improving order accuracy. Comparing both methods helps businesses balance storage capacity with operational agility to enhance overall warehouse performance.

Table of Comparison

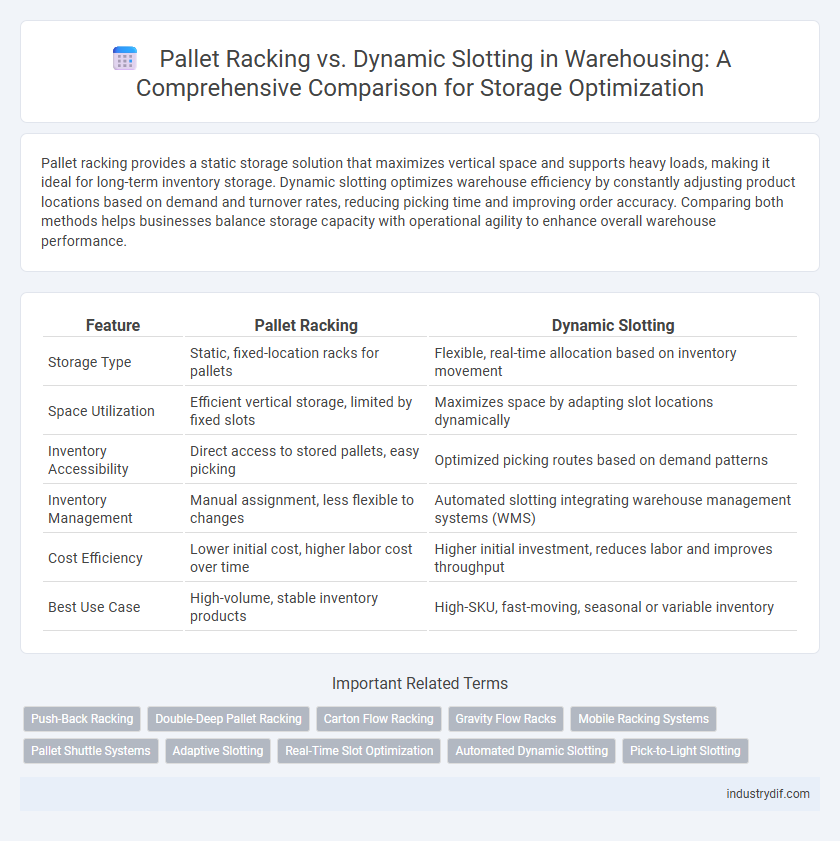

| Feature | Pallet Racking | Dynamic Slotting |

|---|---|---|

| Storage Type | Static, fixed-location racks for pallets | Flexible, real-time allocation based on inventory movement |

| Space Utilization | Efficient vertical storage, limited by fixed slots | Maximizes space by adapting slot locations dynamically |

| Inventory Accessibility | Direct access to stored pallets, easy picking | Optimized picking routes based on demand patterns |

| Inventory Management | Manual assignment, less flexible to changes | Automated slotting integrating warehouse management systems (WMS) |

| Cost Efficiency | Lower initial cost, higher labor cost over time | Higher initial investment, reduces labor and improves throughput |

| Best Use Case | High-volume, stable inventory products | High-SKU, fast-moving, seasonal or variable inventory |

Introduction to Pallet Racking and Dynamic Slotting

Pallet racking systems are engineered structures designed to store materials on pallets efficiently, maximizing vertical space and offering easy access for forklifts in warehouses. Dynamic slotting involves continuously adjusting product locations based on demand patterns to optimize picking efficiency and reduce travel time. Combining pallet racking with dynamic slotting strategies enhances warehouse organization, inventory management, and operational productivity.

Key Differences Between Pallet Racking and Dynamic Slotting

Pallet racking involves fixed storage systems where pallets are stored on upright frames, optimizing vertical space but requiring manual or mechanized retrieval. Dynamic slotting uses software-driven slot assignment to allocate inventory locations based on real-time data such as demand frequency and product velocity, enhancing picking efficiency and adaptability. Key differences include the static physical structure of pallet racking versus the flexible, data-driven organization of dynamic slotting.

Space Optimization: Static vs. Dynamic Storage

Pallet racking systems offer static storage solutions that maximize vertical space by securely holding palletized goods in fixed locations, ensuring organized inventory but sometimes leading to underutilized space during demand fluctuations. Dynamic slotting leverages real-time data and automated systems to adjust storage positions based on product velocity and size, significantly enhancing space utilization and operational efficiency. Employing dynamic slotting strategies can reduce aisle space requirements and improve inventory turnover compared to traditional pallet racking setups.

Flexibility and Adaptability in Warehouse Layouts

Pallet racking offers standardized storage with structured, fixed locations that maximize vertical space but can limit flexibility in fluctuating inventory demands. Dynamic slotting enhances adaptability by continuously reallocating products based on real-time data, optimizing picking efficiency and space utilization in diverse warehouse layouts. Warehouses prioritizing rapid changes and varied product flows benefit from dynamic slotting, whereas those with stable inventory levels may find pallet racking more cost-effective.

Inventory Management Efficiency

Pallet racking systems provide structured storage that maximizes vertical space, enabling higher inventory density and easier stock location through fixed slot assignments. Dynamic slotting optimizes inventory management by continuously reallocating products based on real-time demand and turnover rates, reducing picking times and minimizing stock retrieval errors. Implementing a hybrid approach combining pallet racking infrastructure with dynamic slotting algorithms can significantly enhance overall warehouse storage efficiency and inventory accuracy.

Cost Implications: Installation and Maintenance

Pallet racking systems generally involve higher upfront costs due to materials and installation complexity, requiring robust structural support and precise layout planning. Dynamic slotting, while potentially reducing storage density, offers lower installation expenses and can decrease maintenance costs through its flexible and adaptable configurations. Over time, dynamic slotting may lead to cost savings by optimizing labor efficiency and minimizing downtime compared to fixed pallet racking setups.

Scalability for Growing Warehousing Needs

Pallet racking systems offer a scalable storage solution by allowing vertical expansion and easy reconfiguration to accommodate increased inventory levels in growing warehouses. Dynamic slotting enhances warehouse scalability through automated, data-driven inventory placement that optimizes space utilization and reduces picking times as SKU counts rise. Combining pallet racking with dynamic slotting strategies supports flexible warehouse growth, efficiently managing higher throughput and evolving product assortments.

Impact on Order Picking Speed and Accuracy

Pallet racking systems provide structured storage that facilitates fast, accurate order picking by maintaining clear inventory locations and minimizing travel time. Dynamic slotting adapts storage locations based on real-time order patterns, significantly boosting picking speed and accuracy through optimized product placement. Combining pallet racking with dynamic slotting can reduce order errors and increase throughput by aligning physical storage with demand-driven data.

Safety Considerations and Compliance

Pallet racking systems require strict adherence to load limits and regular inspections to prevent structural failures and ensure worker safety, while dynamic slotting necessitates ongoing monitoring of inventory movement to reduce hazards related to improper storage or stock imbalances. Compliance with OSHA standards and local regulations is essential for both systems, emphasizing secure installation, clear signage, and employee training on safe handling practices. Efficient risk management in pallet racking and dynamic slotting minimizes accidents, supports regulatory compliance, and enhances overall warehouse safety performance.

Choosing the Right Solution for Your Warehouse

Pallet racking offers a robust storage solution ideal for high-density, long-term inventory, maximizing vertical space and supporting heavy loads efficiently. Dynamic slotting enhances warehouse agility by optimizing pick paths and inventory placement based on real-time demand, improving order accuracy and throughput. Selecting the right solution depends on your warehouse's inventory turnover, space constraints, and operational priorities, with many facilities benefiting from a hybrid approach combining static racking and dynamic slotting techniques.

Related Important Terms

Push-Back Racking

Push-back racking offers high-density storage by utilizing gravity-fed carts that move along inclined rails, enabling efficient inventory rotation and maximizing space compared to traditional pallet racking. Dynamic slotting optimizes warehouse performance by adjusting slot assignments based on real-time demand, but push-back racking provides a streamlined solution for storing multiple pallets per SKU with improved accessibility and reduced aisle space requirements.

Double-Deep Pallet Racking

Double-Deep Pallet Racking maximizes warehouse storage density by allowing pallets to be stored two rows deep, reducing aisle space and increasing cubic utilization compared to traditional single-depth systems. Dynamic Slotting, while optimizing inventory flow by assigning products to locations based on demand and velocity, may not fully capitalize on the space efficiency gains achieved by implementing Double-Deep Pallet Racking configurations.

Carton Flow Racking

Pallet racking provides static storage with high-density stacking capabilities, while carton flow racking utilizes dynamic slotting through gravity-fed rollers for efficient picking and replenishment of cartons. Carton flow racks optimize warehouse space by enabling first-in, first-out rotation, reducing labor costs and improving order accuracy in high-velocity fulfillment environments.

Gravity Flow Racks

Gravity flow racks maximize storage efficiency by using inclined rails and rollers to enable automatic product movement, reducing picking time compared to traditional pallet racking. Dynamic slotting optimizes inventory placement based on demand patterns, enhancing throughput and space utilization beyond static pallet racks in warehouse operations.

Mobile Racking Systems

Mobile racking systems enhance warehouse space utilization by allowing pallet racks to move on tracks, eliminating fixed aisles and improving storage density compared to dynamic slotting that relies on predetermined picking locations. These systems optimize inventory management and accessibility, reducing retrieval times and increasing operational efficiency in high-density warehousing environments.

Pallet Shuttle Systems

Pallet shuttle systems optimize warehouse storage by automating pallet movement within high-density racking, significantly outperforming traditional pallet racking in speed and space utilization. Unlike dynamic slotting that rearranges inventory based on demand, pallet shuttles reduce labor costs and increase throughput by enabling seamless, mechanized loading and unloading in narrow aisle configurations.

Adaptive Slotting

Adaptive slotting enhances warehouse efficiency by dynamically allocating storage locations based on real-time demand and product velocity, contrasting with traditional pallet racking that offers fixed storage positions. Integrating adaptive slotting with pallet racking systems optimizes space utilization and reduces picking times, driving operational responsiveness and inventory accuracy.

Real-Time Slot Optimization

Real-time slot optimization in warehousing leverages dynamic slotting systems to continually adjust inventory placement based on current demand and product velocity, significantly improving space utilization and picking efficiency. Pallet racking offers fixed storage locations but lacks the flexibility of dynamic slotting, which uses real-time data analytics to enhance throughput and reduce handling times.

Automated Dynamic Slotting

Automated Dynamic Slotting enhances warehouse efficiency by continuously analyzing inventory velocity, order patterns, and storage conditions to optimize product placement in real time, unlike traditional Pallet Racking which relies on fixed storage locations. This advanced system reduces picking time and improves space utilization by dynamically adjusting slots based on data-driven demand forecasts and operational priorities.

Pick-to-Light Slotting

Pick-to-Light slotting enhances warehouse efficiency by guiding operators directly to pallet locations through illuminated indicators, reducing picking errors and accelerating order fulfillment. Unlike traditional pallet racking, dynamic pick-to-light systems optimize slotting based on real-time demand patterns, increasing storage density while minimizing travel time and labor costs.

Pallet Racking vs Dynamic Slotting Infographic

industrydif.com

industrydif.com