Conveyor systems offer a fixed, high-throughput solution for transporting goods within warehouses, ideal for repetitive tasks and heavy loads. Autonomous Mobile Robots (AMRs) provide flexibility and scalability, navigating dynamic environments and adapting to changing workflows without extensive infrastructure. Choosing between conveyor systems and AMRs depends on warehouse layout, volume variability, and desired operational agility.

Table of Comparison

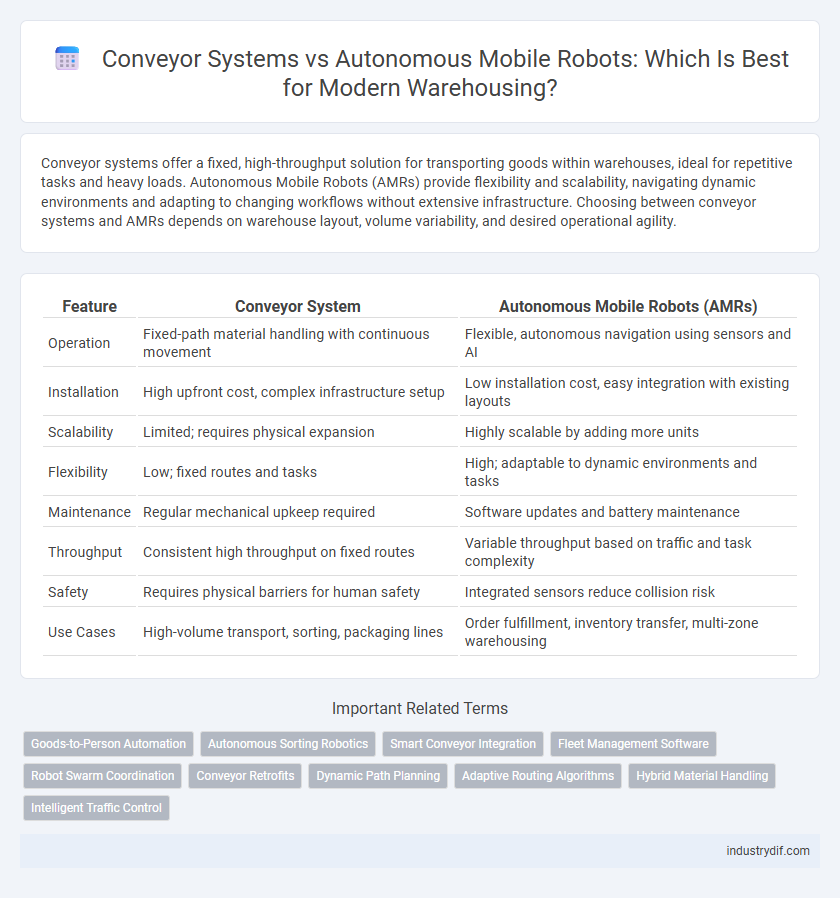

| Feature | Conveyor System | Autonomous Mobile Robots (AMRs) |

|---|---|---|

| Operation | Fixed-path material handling with continuous movement | Flexible, autonomous navigation using sensors and AI |

| Installation | High upfront cost, complex infrastructure setup | Low installation cost, easy integration with existing layouts |

| Scalability | Limited; requires physical expansion | Highly scalable by adding more units |

| Flexibility | Low; fixed routes and tasks | High; adaptable to dynamic environments and tasks |

| Maintenance | Regular mechanical upkeep required | Software updates and battery maintenance |

| Throughput | Consistent high throughput on fixed routes | Variable throughput based on traffic and task complexity |

| Safety | Requires physical barriers for human safety | Integrated sensors reduce collision risk |

| Use Cases | High-volume transport, sorting, packaging lines | Order fulfillment, inventory transfer, multi-zone warehousing |

Introduction to Conveyor Systems and Autonomous Mobile Robots in Warehousing

Conveyor systems in warehousing provide a fixed infrastructure for transporting goods along predetermined paths, enhancing efficiency in material handling by reducing manual labor and increasing throughput. Autonomous mobile robots (AMRs) offer flexible, software-driven navigation that adapts to dynamic warehouse environments, enabling real-time routing and on-demand material movement without the need for fixed tracks. Both technologies optimize warehouse operations by streamlining inventory flow but differ in scalability, cost, and adaptability to changing warehouse layouts.

Key Differences Between Conveyor Systems and AMRs

Conveyor systems operate on fixed tracks and are designed for continuous movement of goods, while Autonomous Mobile Robots (AMRs) navigate dynamically within warehouses using sensors and AI for flexible transport routes. Conveyor systems excel in high-volume, repetitive tasks with minimal human intervention, whereas AMRs offer adaptability and scalability for complex environments requiring varied pick-and-place operations. Maintenance requirements differ, with conveyors needing regular mechanical checks, while AMRs require software updates and battery management.

Efficiency and Speed: Conveyor Systems vs AMRs

Conveyor systems provide continuous, high-speed material transport along fixed pathways, optimizing throughput for repetitive tasks and large volumes. Autonomous Mobile Robots (AMRs) offer flexible routing and dynamic task management, improving efficiency in complex or changing warehouse layouts. AMRs adapt quickly to varying workloads while conveyor systems excel in consistent, predictable flow environments.

Flexibility and Scalability in Modern Warehouses

Conveyor systems provide high throughput and consistent material flow but lack the flexibility to easily adapt to layout changes or varied product types, limiting scalability in dynamic warehouse environments. Autonomous Mobile Robots (AMRs) offer enhanced flexibility by navigating complex, changing warehouse layouts without fixed infrastructure, enabling scalable operations through modular deployment and easy reprogramming. Modern warehouses increasingly favor AMRs for their ability to quickly scale and adjust to fluctuating inventory demands and diverse workflows.

Initial Investment and Long-Term Costs

Conveyor systems require a high initial investment in infrastructure and installation but offer predictable maintenance costs over time. Autonomous Mobile Robots (AMRs) entail lower upfront expenses and greater flexibility but may incur higher long-term costs due to software updates and battery replacements. Evaluating total cost of ownership depends on warehouse scale, operational complexity, and adaptability requirements.

Safety Considerations: Conveyors vs Autonomous Mobile Robots

Conveyor systems pose fixed safety risks such as pinch points and entrapment zones requiring physical barriers and emergency stop mechanisms, while autonomous mobile robots (AMRs) rely on advanced sensors and real-time obstacle detection to dynamically navigate and avoid collisions. AMRs reduce human exposure to repetitive strain and hazardous lifting but require rigorous software safety protocols and regular maintenance to prevent operational failures or erratic behavior. Effective warehouse safety combines physical safeguards of conveyors with adaptive monitoring and fail-safe algorithms embedded in AMRs to minimize workplace accidents.

Integration with Warehouse Management Systems (WMS)

Conveyor systems offer seamless integration with Warehouse Management Systems (WMS) through established protocols and centralized control, enabling real-time tracking and efficient material flow. Autonomous Mobile Robots (AMRs) utilize advanced sensor fusion and AI-driven navigation, providing dynamic interaction with WMS for flexible routing and adaptive task execution. Both technologies enhance operational efficiency, but AMRs deliver superior scalability and responsiveness to fluctuating warehouse demands.

Maintenance Requirements and Downtime Risks

Conveyor systems demand frequent mechanical inspections and belt replacements, leading to scheduled maintenance that can disrupt warehouse operations. Autonomous mobile robots require software updates and sensor calibrations but generally experience less unplanned downtime due to their adaptive navigation capabilities. Choosing between these solutions involves balancing conveyor's predictable maintenance routines against the potential for reduced downtime and flexible deployment offered by autonomous mobile robots.

Space Utilization and Layout Adaptability

Conveyor systems optimize space by creating fixed, linear pathways that maximize vertical and horizontal storage density but limit layout flexibility due to their rigid infrastructure. Autonomous Mobile Robots (AMRs) enhance space utilization by navigating dynamic routes, enabling modular and reconfigurable warehouse layouts that adapt quickly to changing inventory demands. AMRs reduce the need for extensive fixed equipment, allowing more versatile storage configurations and improved aisle accessibility compared to traditional conveyor installations.

Choosing the Right Material Handling Solution for Your Warehouse

Evaluating conveyor systems and autonomous mobile robots (AMRs) requires analyzing warehouse layout, throughput needs, and scalability. Conveyor systems excel in high-volume, linear transport tasks with lower variability, while AMRs offer flexibility for dynamic routing and inventory changes in complex environments. Selecting the optimal material handling solution hinges on balancing operational efficiency, integration costs, and future growth projections.

Related Important Terms

Goods-to-Person Automation

Conveyor systems streamline goods-to-person automation by providing continuous, high-speed transport of items, ideal for large-scale, predictable warehouse operations. Autonomous Mobile Robots (AMRs) offer flexible, scalable solutions with dynamic routing and adaptive handling, enhancing efficiency in diverse, high-mix fulfillment environments.

Autonomous Sorting Robotics

Autonomous sorting robotics in warehousing significantly enhance accuracy and speed compared to traditional conveyor systems by leveraging AI-driven vision and machine learning algorithms for efficient item identification and categorization. These robots enable flexible, scalable sorting operations with reduced infrastructure costs and improved adaptability to varying order volumes and warehouse layouts.

Smart Conveyor Integration

Smart conveyor integration enhances warehouse efficiency by enabling seamless coordination between conveyor systems and autonomous mobile robots (AMRs), optimizing material flow and reducing manual handling. This integration leverages real-time data analytics and IoT connectivity to dynamically route goods, increase throughput, and minimize operational downtime.

Fleet Management Software

Fleet management software for conveyor systems offers centralized control with fixed routes and predictable workflows, optimizing throughput and minimizing downtime. In contrast, autonomous mobile robots rely on advanced fleet management platforms that provide dynamic path planning, real-time obstacle avoidance, and scalable coordination for flexible warehouse operations.

Robot Swarm Coordination

Robot swarm coordination in warehousing enables autonomous mobile robots to collaboratively optimize material handling efficiency, outperforming traditional conveyor systems through dynamic route planning and real-time obstacle avoidance. This decentralized approach reduces bottlenecks and improves throughput by leveraging AI-powered communication protocols and adaptive task allocation among multiple robots.

Conveyor Retrofits

Conveyor retrofits enhance existing warehouse automation by integrating smart sensors and IoT technologies, improving throughput and reducing downtime while maintaining structural infrastructure. Autonomous Mobile Robots offer flexible and scalable material handling but retrofitting conveyors maximizes current assets, enabling cost-effective upgrades with minimal disruption to operations.

Dynamic Path Planning

Conveyor systems provide fixed, predetermined routes ideal for high-throughput environments but lack flexibility in dynamic path adjustments, often leading to bottlenecks during workflow changes. Autonomous Mobile Robots leverage advanced dynamic path planning algorithms to navigate variable warehouse layouts in real-time, optimizing route efficiency and adapting seamlessly to fluctuating operational demands.

Adaptive Routing Algorithms

Adaptive routing algorithms in conveyor systems optimize fixed path utilization by dynamically adjusting item flow to prevent bottlenecks, enhancing throughput efficiency in structured warehouse environments. In contrast, autonomous mobile robots leverage machine learning-based adaptive routing to navigate flexible, real-time routes throughout the facility, improving responsiveness and scalability for complex, high-mix order fulfillment operations.

Hybrid Material Handling

Hybrid material handling in warehousing combines conveyor systems with autonomous mobile robots (AMRs) to optimize efficiency and flexibility. Conveyor systems provide consistent, high-volume transport for repetitive tasks, while AMRs enhance adaptability by dynamically navigating complex layouts, resulting in a scalable solution that maximizes throughput and minimizes downtime.

Intelligent Traffic Control

Intelligent traffic control in conveyor systems relies on fixed routing paths and centralized management to optimize item flow, whereas autonomous mobile robots (AMRs) use dynamic routing algorithms and real-time data to navigate complex warehouse environments efficiently. AMRs enhance scalability and adaptability by autonomously adjusting routes to avoid congestion, improving throughput compared to the predetermined, linear movement of conveyors.

Conveyor System vs Autonomous Mobile Robots Infographic

industrydif.com

industrydif.com