Cold storage facilities provide temperature-controlled environments crucial for preserving perishable goods but often require manual handling which can increase labor costs and human error. Automated cold chain solutions integrate advanced robotics, sensors, and real-time monitoring to enhance efficiency, accuracy, and traceability throughout the supply chain. Implementing automated cold chain systems reduces spoilage risks while optimizing inventory management and operational workflows in warehousing.

Table of Comparison

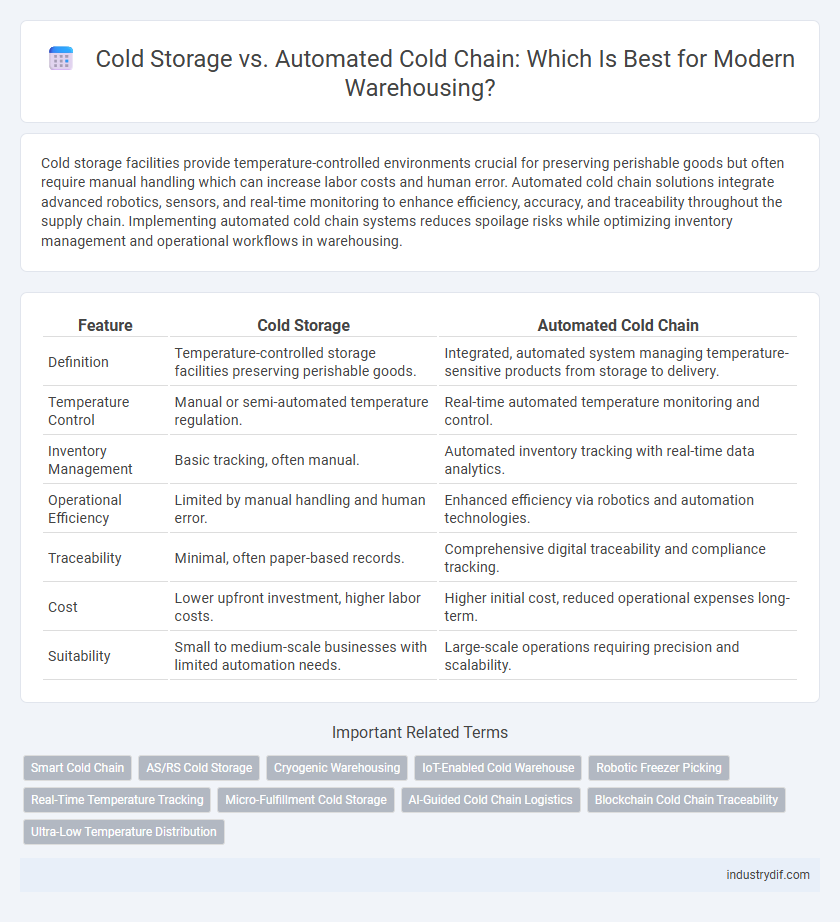

| Feature | Cold Storage | Automated Cold Chain |

|---|---|---|

| Definition | Temperature-controlled storage facilities preserving perishable goods. | Integrated, automated system managing temperature-sensitive products from storage to delivery. |

| Temperature Control | Manual or semi-automated temperature regulation. | Real-time automated temperature monitoring and control. |

| Inventory Management | Basic tracking, often manual. | Automated inventory tracking with real-time data analytics. |

| Operational Efficiency | Limited by manual handling and human error. | Enhanced efficiency via robotics and automation technologies. |

| Traceability | Minimal, often paper-based records. | Comprehensive digital traceability and compliance tracking. |

| Cost | Lower upfront investment, higher labor costs. | Higher initial cost, reduced operational expenses long-term. |

| Suitability | Small to medium-scale businesses with limited automation needs. | Large-scale operations requiring precision and scalability. |

Understanding Cold Storage in Warehousing

Cold storage in warehousing refers to specialized facilities designed to maintain low temperatures for perishable goods, ensuring product quality and safety throughout the supply chain. These warehouses utilize refrigeration systems, insulated walls, and temperature monitoring technologies to preserve items like food, pharmaceuticals, and chemicals. Effective cold storage minimizes spoilage, extends shelf life, and supports compliance with regulatory standards in temperature-sensitive logistics.

What is an Automated Cold Chain?

An Automated Cold Chain integrates advanced robotics, IoT sensors, and real-time data analytics to manage temperature-sensitive inventory with precision and efficiency. This system ensures constant monitoring and automatic adjustments of storage conditions, minimizing human error and preserving product quality across warehousing operations. Automated Cold Chains enhance traceability and streamline distribution in sectors like pharmaceuticals, food, and biotechnology.

Key Differences: Cold Storage vs Automated Cold Chain

Cold Storage facilities maintain low temperatures to preserve perishable goods but rely heavily on manual processes for inventory management and handling. Automated Cold Chain systems integrate robotics, sensors, and IoT technology to enable real-time temperature monitoring, seamless inventory tracking, and reduced human intervention. Key differences include improved efficiency, accuracy, and risk mitigation in Automated Cold Chains compared to traditional Cold Storage methods.

Temperature Management and Control

Cold storage facilities maintain consistent low temperatures primarily through static refrigeration systems, ensuring product preservation but often requiring manual monitoring and intervention. Automated cold chain solutions integrate advanced sensors, real-time temperature tracking, and AI-driven controls to optimize temperature regulation, minimize fluctuations, and enhance compliance with safety standards. These technologies reduce spoilage risk by enabling proactive adjustments and providing detailed temperature logs throughout the supply chain.

Efficiency and Operational Speed

Cold storage facilities provide basic temperature control but often involve manual handling, leading to slower operational speeds and increased labor costs. Automated cold chain systems leverage robotics, IoT sensors, and real-time data analytics to optimize temperature maintenance while significantly enhancing efficiency through rapid inventory management and reduced human error. Implementing automated cold chain solutions results in faster order fulfillment, improved product traceability, and lower energy consumption compared to traditional cold storage.

Labor Requirements and Automation Benefits

Cold storage facilities traditionally rely on extensive manual labor for tasks such as loading, unloading, and inventory management, leading to higher labor costs and increased risk of human error. Automated cold chain systems integrate robotics, sensors, and real-time monitoring to optimize temperature control and streamline operations, significantly reducing the need for manual intervention. This automation enhances efficiency, minimizes labor requirements, and ensures stricter compliance with food safety standards in cold warehousing environments.

Cost Implications and ROI Analysis

Cold storage facilities typically incur high energy and maintenance costs due to continuous refrigeration needs, impacting overall operational expenses. Automated cold chain systems, although requiring substantial initial investment in technology and infrastructure, offer optimized temperature control and reduced labor costs, enhancing efficiency and minimizing product spoilage. An ROI analysis reveals that automated cold chain integrations yield faster payback periods through improved inventory management and decreased waste, making them economically advantageous over traditional cold storage in the long term.

Scalability and Flexibility in Cold Logistics

Automated cold chain systems offer superior scalability in cold logistics by integrating advanced robotics and IoT sensors, enabling seamless expansion without disrupting operations. Cold storage facilities, while essential for temperature control, often face limitations in flexibility due to fixed infrastructure and manual handling processes. Leveraging automation enhances real-time inventory management and dynamic route optimization, driving efficiency and adaptability in temperature-sensitive supply chains.

Safety, Compliance, and Risk Management

Cold storage facilities require stringent temperature controls and adherence to food safety regulations to prevent spoilage and contamination, emphasizing manual monitoring and compliance checks. Automated cold chain systems enhance safety and risk management by integrating real-time temperature tracking, automated alerts, and compliance documentation, reducing human error and ensuring consistent regulatory adherence. These advanced systems enable proactive risk mitigation and streamline safety protocols, optimizing cold storage reliability and compliance in warehousing operations.

Choosing Between Cold Storage and Automated Cold Chain

Choosing between cold storage and automated cold chain solutions depends on factors such as inventory volume, temperature sensitivity, and operational efficiency requirements. Cold storage tanks offer traditional, cost-effective temperature-controlled environments ideal for static inventory but lack real-time monitoring and automation capabilities. Automated cold chain systems provide integrated temperature tracking, faster retrieval processes, and enhanced data analytics, making them suitable for businesses prioritizing precision, compliance, and scalability in perishable goods management.

Related Important Terms

Smart Cold Chain

Smart cold chain systems enhance traditional cold storage by integrating IoT sensors, real-time temperature monitoring, and automated alerts to ensure optimal preservation of perishable goods. These technologies minimize spoilage, improve inventory management, and enable precise tracking within automated cold chain logistics, boosting efficiency and reducing operational costs.

AS/RS Cold Storage

AS/RS cold storage systems offer enhanced inventory accuracy and faster retrieval times compared to traditional cold storage, optimizing temperature-controlled warehousing operations. Automated storage and retrieval systems (AS/RS) integrate robotic handling with precise climate regulation, reducing human error and improving energy efficiency in cold chain logistics.

Cryogenic Warehousing

Cryogenic warehousing utilizes ultra-low temperature storage, preserving perishables and biological samples with liquid nitrogen or carbon dioxide, offering superior preservation compared to traditional cold storage that relies on mechanical refrigeration. Automated cold chain systems integrate cryogenic warehousing with real-time temperature monitoring and robotics, enhancing inventory accuracy, reducing human error, and ensuring compliance with strict regulatory standards in pharmaceuticals and biotech industries.

IoT-Enabled Cold Warehouse

IoT-enabled cold warehouses enhance cold storage efficiency by providing real-time temperature monitoring, predictive maintenance, and automated inventory management, reducing spoilage and energy costs. Unlike traditional cold storage, automated cold chain systems integrate IoT sensors and data analytics to ensure precise environmental control and seamless product traceability throughout the supply chain.

Robotic Freezer Picking

Robotic freezer picking in automated cold chain systems enhances warehousing efficiency by reducing human exposure to extreme temperatures and minimizing picking errors, which improves order accuracy and speed. Cold storage facilities benefit from this technology through optimized space utilization and real-time inventory management, ensuring faster turnover and improved product traceability in temperature-sensitive supply chains.

Real-Time Temperature Tracking

Real-time temperature tracking in cold storage warehouses ensures precise monitoring of perishable goods, minimizing spoilage and compliance risks. Automated cold chain systems enhance this capability by integrating IoT sensors and AI analytics, enabling continuous data capture and immediate response to temperature deviations.

Micro-Fulfillment Cold Storage

Micro-fulfillment cold storage integrates automated cold chain technology to enhance temperature-controlled inventory management, reducing spoilage and accelerating order fulfillment for perishable goods. This advanced system optimizes space utilization and ensures precise climate control through robotics and IoT sensors, outperforming traditional cold storage solutions in efficiency and scalability.

AI-Guided Cold Chain Logistics

AI-guided cold chain logistics optimize temperature-sensitive warehousing by integrating real-time data analytics and predictive maintenance, enhancing inventory accuracy and minimizing spoilage risks. Automated cold storage systems leverage AI for dynamic climate control and efficient route planning, ensuring the integrity and freshness of perishable goods throughout the supply chain.

Blockchain Cold Chain Traceability

Cold storage warehouses that implement blockchain cold chain traceability enhance transparency and security by providing immutable records of temperature-sensitive goods throughout the supply chain. Automated cold chain systems integrated with blockchain technology enable real-time monitoring and verification, reducing spoilage risks and ensuring compliance with regulatory standards.

Ultra-Low Temperature Distribution

Cold storage facilities maintain ultra-low temperature environments crucial for preserving sensitive products such as vaccines, biological samples, and pharmaceuticals, ensuring consistent thermal conditions throughout the storage duration. Automated cold chain systems enhance ultra-low temperature distribution by integrating real-time temperature monitoring, robotic handling, and optimized logistics, minimizing human error and preventing temperature excursions that could compromise product integrity.

Cold Storage vs Automated Cold Chain Infographic

industrydif.com

industrydif.com