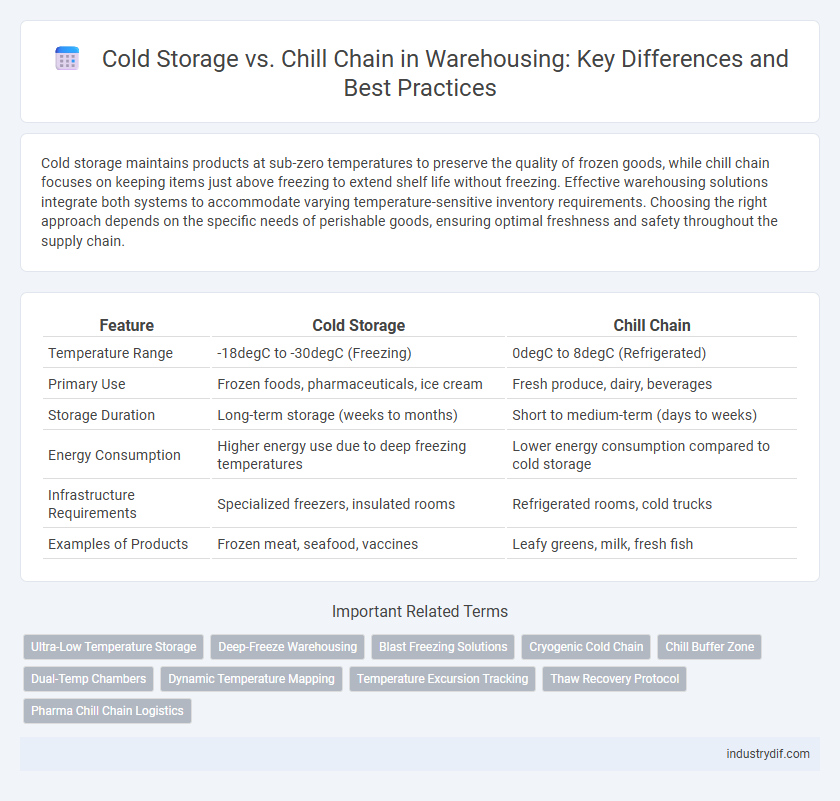

Cold storage maintains products at sub-zero temperatures to preserve the quality of frozen goods, while chill chain focuses on keeping items just above freezing to extend shelf life without freezing. Effective warehousing solutions integrate both systems to accommodate varying temperature-sensitive inventory requirements. Choosing the right approach depends on the specific needs of perishable goods, ensuring optimal freshness and safety throughout the supply chain.

Table of Comparison

| Feature | Cold Storage | Chill Chain |

|---|---|---|

| Temperature Range | -18degC to -30degC (Freezing) | 0degC to 8degC (Refrigerated) |

| Primary Use | Frozen foods, pharmaceuticals, ice cream | Fresh produce, dairy, beverages |

| Storage Duration | Long-term storage (weeks to months) | Short to medium-term (days to weeks) |

| Energy Consumption | Higher energy use due to deep freezing temperatures | Lower energy consumption compared to cold storage |

| Infrastructure Requirements | Specialized freezers, insulated rooms | Refrigerated rooms, cold trucks |

| Examples of Products | Frozen meat, seafood, vaccines | Leafy greens, milk, fresh fish |

Understanding Cold Storage in Warehousing

Cold storage in warehousing involves maintaining goods at temperatures below 0degC to preserve perishable items such as frozen foods, pharmaceuticals, and chemicals. Unlike chill chain systems that typically operate between 0degC and 8degC for short-term temperature control, cold storage ensures long-term preservation by preventing microbial growth and enzymatic activity. Efficient refrigeration units, insulated structures, and continuous temperature monitoring are critical components in cold storage facilities to maintain product quality and extend shelf life.

What is the Chill Chain?

The chill chain is a temperature-controlled supply chain process that maintains products at specific low temperatures between 0degC and 8degC to preserve freshness and prevent spoilage. Unlike cold storage, which involves static temperature-controlled facilities, the chill chain encompasses the entire journey, including transportation, handling, and storage, ensuring consistent cooling throughout. This is critical for perishable goods such as dairy, pharmaceuticals, and fresh produce, where precise temperature management directly impacts quality and safety.

Key Differences: Cold Storage vs Chill Chain

Cold storage facilities maintain temperatures below freezing, typically between -18degC to -40degC, to preserve frozen goods for extended periods, while chill chains operate within a refrigerated range of 0degC to 8degC, suitable for perishable items that require cooling but not freezing. Cold storage ensures long-term preservation of products like frozen foods and pharmaceuticals, whereas chill chains support continuous temperature-controlled environments throughout transportation and storage, minimizing spoilage of fresh produce and temperature-sensitive goods. The key difference lies in temperature range and supply chain integration, with cold storage emphasizing static preservation and chill chains focusing on dynamic, end-to-end temperature management.

Temperature Requirements: Cold Storage vs Chill Chain

Cold storage facilities maintain temperatures typically below -18degC to preserve frozen goods, ensuring long-term shelf life and quality. Chill chain environments regulate temperatures between 0degC and 8degC, ideal for perishable items like dairy, pharmaceuticals, and fresh produce requiring consistent cool conditions. Precise temperature control in both cold storage and chill chain operations is critical to preventing spoilage and maintaining product safety throughout the supply chain.

Typical Products: Cold Storage vs Chill Chain

Cold storage warehouses are designed to maintain temperatures below 0degC, ideal for storing frozen foods, pharmaceuticals, and certain chemical products requiring long-term preservation. Chill chain facilities operate within a range of 0degC to 8degC, preserving perishable goods like dairy, fresh fruits, vegetables, and vaccines that need consistent refrigeration but not freezing. Selecting between cold storage and chill chain depends on the temperature sensitivity and shelf life requirements of the typical products being handled.

Infrastructure and Technology in Cold Storage

Cold storage facilities utilize advanced refrigeration systems with precise temperature control and insulation technologies to maintain sub-zero environments essential for preserving perishable goods. Infrastructure in cold storage includes high-efficiency compressors, vapor compression cycles, and automated monitoring systems to minimize energy consumption and ensure consistent cooling performance. Technology integration such as IoT sensors and real-time data analytics enhances inventory management and predictive maintenance, optimizing storage conditions and reducing spoilage risk in cold chain logistics.

Logistics and Handling in the Chill Chain

Chill chain logistics require precise temperature control between 0degC and 8degC to maintain product integrity during transportation and storage, often involving refrigerated trucks and specialized packaging. Handling in the chill chain demands continuous monitoring with IoT-enabled sensors to prevent temperature breaches and contamination risks. Efficient coordination among warehouses, transportation, and distribution centers ensures minimal transit time and preserves the quality of perishable goods.

Compliance and Regulatory Standards

Cold storage facilities ensure compliance with strict regulatory standards by maintaining temperatures below 0degC, essential for preserving frozen goods and preventing microbial growth. Chill chain logistics operate within 0degC to 8degC, adhering to food safety regulations that reduce spoilage and maintain nutritional quality during transportation and storage. Both systems require certified temperature monitoring and documentation to meet industry requirements such as FDA, HACCP, and ISO standards.

Challenges in Managing Cold Storage and Chill Chains

Managing cold storage and chill chains involves significant challenges such as maintaining precise temperature control to prevent spoilage of perishable goods. Ensuring consistent monitoring and real-time data logging is critical to avoid temperature fluctuations that can compromise product quality and safety. Logistics complexities, including transportation delays and equipment malfunctions, further complicate the integrity of cold storage environments and chill chain operations.

Future Trends in Cold Storage and Chill Chain Logistics

Emerging technologies in cold storage and chill chain logistics are driving enhanced temperature control accuracy, reducing thermal fluctuations to preserve product integrity. Integration of IoT sensors and AI-powered analytics enables real-time monitoring and predictive maintenance, optimizing supply chain efficiency and minimizing spoilage. Sustainable innovations, including energy-efficient refrigeration systems and renewable energy adoption, are shaping the future landscape of cold storage facilities and chill chain networks globally.

Related Important Terms

Ultra-Low Temperature Storage

Ultra-low temperature storage in cold storage facilities maintains consistent temperatures between -40degC and -86degC, essential for preserving sensitive biomedical samples and pharmaceuticals. Chill chain systems, operating primarily between 0degC and 8degC, support less extreme temperature requirements for perishables but cannot maintain the stability needed for ultra-low temperature preservation.

Deep-Freeze Warehousing

Deep-freeze warehousing is essential for cold storage solutions, maintaining temperatures below -18degC to preserve perishable goods such as frozen foods and pharmaceuticals. Unlike chill chain systems that manage moderate cooling between 0degC and 8degC, deep-freeze facilities require specialized insulation and refrigeration technology to ensure long-term product integrity and prevent spoilage.

Blast Freezing Solutions

Blast freezing solutions in cold storage provide rapid temperature reduction to preserve product quality and extend shelf life, making them essential for frozen goods requiring long-term storage. Chill chain systems maintain a controlled temperature environment for perishable items, but lack the intense freezing capability and speed of blast freezers critical for preventing ice crystal formation and maintaining cellular integrity in food products.

Cryogenic Cold Chain

Cryogenic cold chain systems utilize ultra-low temperatures achieved through liquid nitrogen or carbon dioxide to preserve sensitive biological materials, outperforming traditional cold storage and chill chain methods that maintain temperatures typically between -20degC and 4degC. This advanced cryogenic technology ensures longer shelf life and maintains the integrity of pharmaceuticals, vaccines, and perishable goods during warehousing and transportation.

Chill Buffer Zone

Chill buffer zones in cold storage facilities maintain a stable temperature range between 0degC and 8degC, crucial for preserving the integrity of perishable goods during short-term holding. These buffer zones optimize chill chain logistics by reducing temperature fluctuations, thereby extending product shelf life and minimizing spoilage.

Dual-Temp Chambers

Dual-temp chambers in warehousing combine cold storage and chill chain environments within a single facility, enabling precise temperature control for diverse product types. This integration enhances supply chain efficiency by maintaining optimal conditions for both frozen and refrigerated goods, minimizing spoilage and energy costs.

Dynamic Temperature Mapping

Dynamic temperature mapping in cold storage facilities enables precise monitoring and control of temperature fluctuations, ensuring optimal preservation of perishable goods. In chill chain logistics, this technology provides real-time data that enhances compliance with safety standards and reduces spoilage by maintaining consistent cold environments throughout the supply chain.

Temperature Excursion Tracking

Temperature excursion tracking in cold storage systems ensures precise monitoring of sub-zero environments, minimizing risks of product spoilage and maintaining compliance with industry standards. Chill chain solutions extend temperature control above freezing, employing real-time sensors to detect deviations rapidly and preserve perishable goods' quality throughout distribution.

Thaw Recovery Protocol

Thaw recovery protocol in cold storage involves controlled temperature management to minimize cellular damage and preserve product integrity during the transition from frozen to chilled states. In contrast, chill chain thaw recovery emphasizes maintaining consistent low temperatures throughout the distribution network to prevent microbial growth and extend shelf life.

Pharma Chill Chain Logistics

Pharma chill chain logistics requires maintaining precise temperature-controlled environments, typically between 2degC to 8degC, to ensure the stability and efficacy of pharmaceutical products during transportation and storage. Cold storage facilities provide static low-temperature conditions crucial for long-term preservation, while chill chain logistics integrate dynamic temperature monitoring and rapid handling processes to maintain product integrity from manufacturing to administration.

Cold Storage vs Chill Chain Infographic

industrydif.com

industrydif.com