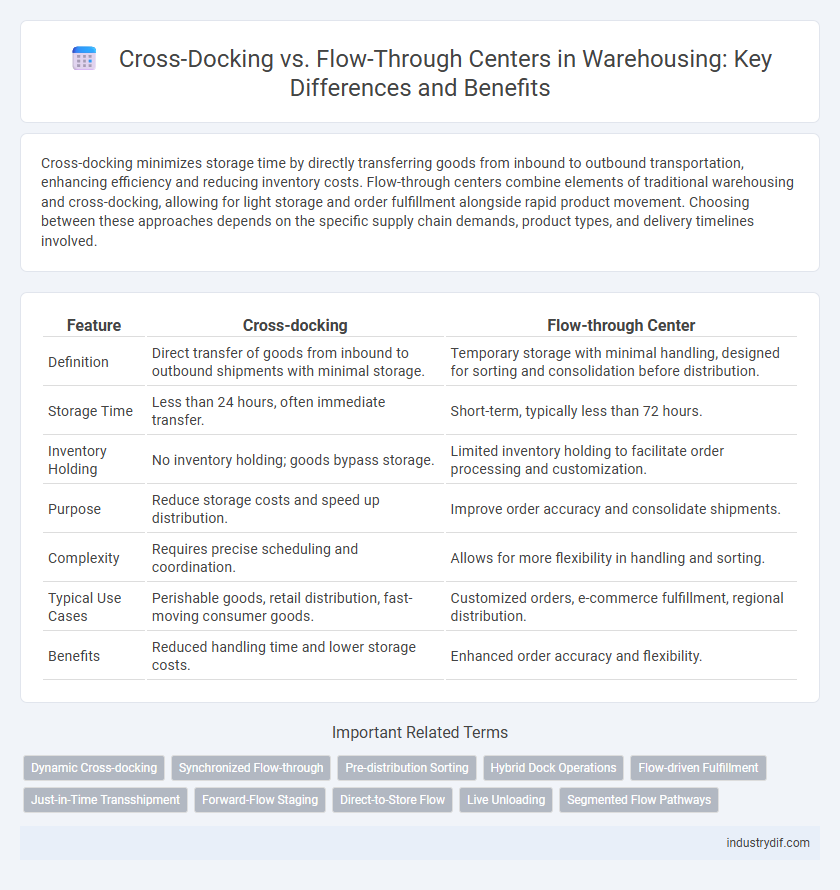

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, enhancing efficiency and reducing inventory costs. Flow-through centers combine elements of traditional warehousing and cross-docking, allowing for light storage and order fulfillment alongside rapid product movement. Choosing between these approaches depends on the specific supply chain demands, product types, and delivery timelines involved.

Table of Comparison

| Feature | Cross-docking | Flow-through Center |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound shipments with minimal storage. | Temporary storage with minimal handling, designed for sorting and consolidation before distribution. |

| Storage Time | Less than 24 hours, often immediate transfer. | Short-term, typically less than 72 hours. |

| Inventory Holding | No inventory holding; goods bypass storage. | Limited inventory holding to facilitate order processing and customization. |

| Purpose | Reduce storage costs and speed up distribution. | Improve order accuracy and consolidate shipments. |

| Complexity | Requires precise scheduling and coordination. | Allows for more flexibility in handling and sorting. |

| Typical Use Cases | Perishable goods, retail distribution, fast-moving consumer goods. | Customized orders, e-commerce fulfillment, regional distribution. |

| Benefits | Reduced handling time and lower storage costs. | Enhanced order accuracy and flexibility. |

Introduction to Cross-docking and Flow-through Centers

Cross-docking is a logistics practice where incoming goods are directly transferred from inbound to outbound transportation with minimal or no storage time, streamlining the supply chain and reducing inventory holding costs. Flow-through centers function by receiving products, performing minimal sorting or repackaging, and quickly dispatching them without long-term storage, enhancing order fulfillment speed and efficiency. Both strategies aim to improve supply chain responsiveness and reduce lead times in warehousing operations.

Key Definitions in Modern Warehousing

Cross-docking in modern warehousing involves the direct transfer of products from inbound to outbound transportation with minimal or no storage time, enhancing efficiency by reducing inventory holding costs. A flow-through center similarly facilitates rapid movement of goods but integrates value-added processes such as sorting, packaging, and light assembly before dispatch. Both methods optimize supply chain velocity, yet cross-docking prioritizes speed while flow-through centers emphasize customization and added service functionality.

Core Processes: Cross-docking vs Flow-through

Cross-docking minimizes storage time by directly transferring incoming goods to outbound transportation, streamlining inventory flow and reducing handling costs. Flow-through centers combine receiving and order picking in a single process, enabling immediate order fulfillment without traditional warehousing. Both core processes enhance supply chain efficiency but differ in handling inventory staging and order processing speeds.

Inventory Handling and Turnaround Speed

Cross-docking minimizes inventory handling by directly transferring goods from receiving to shipping docks, significantly reducing storage time and accelerating turnaround speed. Flow-through centers involve temporary inventory storage and sorting, enabling better order customization but increasing handling complexity and longer dwell times. Choosing between the two depends on prioritizing rapid throughput versus flexible inventory management.

Cost Implications: Labor, Space, and Equipment

Cross-docking minimizes labor costs by reducing handling and storage time, while flow-through centers incur higher labor expenses due to sorting and re-packaging activities. Space utilization is more efficient in cross-docking, as goods move directly from inbound to outbound docks without prolonged storage, whereas flow-through centers require larger areas for staging and processing inventory. Equipment costs in cross-docking primarily involve conveyor systems and docking infrastructure, whereas flow-through centers demand investment in sorting machinery and additional storage solutions.

Technology Utilization in Each Model

Cross-docking relies heavily on real-time inventory management systems and advanced scanning technologies to facilitate rapid sorting and immediate transfer of goods, minimizing storage time. Flow-through centers integrate warehouse management systems (WMS) with automation technologies such as conveyor belts and robotic sorters to streamline product flow from receiving to shipping without traditional warehousing. Both models leverage data analytics and Internet of Things (IoT) sensors to optimize operational efficiency and enhance supply chain visibility.

Industries Best Suited for Cross-docking

Cross-docking is highly effective in industries with high-volume, fast-moving products such as retail, food and beverage, and automotive sectors, where rapid turnover and minimized storage are critical. Perishable goods and just-in-time manufacturing benefit from cross-docking's ability to reduce handling time and inventory holding costs. In contrast, flow-through centers suit industries requiring more extensive product sorting and temporary storage, such as electronics and pharmaceuticals.

Sectors Benefiting from Flow-through Centers

Flow-through centers optimize inventory flow by enabling direct product movement from receiving to shipping without long-term storage, benefiting sectors with high product turnover such as retail, e-commerce, and perishables. These industries leverage flow-through centers to reduce handling time, minimize storage costs, and enhance delivery speed, critical for maintaining fresh stock and meeting consumer demand. The streamlined process supports just-in-time inventory strategies, improving supply chain efficiency in fast-paced market environments.

Major Advantages and Challenges Compared

Cross-docking reduces storage needs and shortens delivery times by transferring goods directly from inbound to outbound transportation, minimizing inventory holding costs but requiring precise coordination and real-time information flow. Flow-through centers combine cross-docking and light storage, enabling better handling of demand variability and order customization yet increasing operational complexity and space requirements. Both systems improve supply chain efficiency but must balance trade-offs between speed, flexibility, and infrastructure investment.

Choosing the Right Strategy for Your Supply Chain

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, ideal for high-velocity products with minimal handling. Flow-through centers combine limited storage with efficient sorting and consolidation, balancing inventory holding with rapid order fulfillment for diverse product lines. Selecting between cross-docking and flow-through strategies depends on product turnover rates, order complexity, and supply chain agility requirements.

Related Important Terms

Dynamic Cross-docking

Dynamic Cross-docking in warehousing streamlines logistics by immediately transferring products from inbound to outbound transportation with minimal or no storage time, reducing handling costs and improving delivery speed. Unlike Flow-through Centers that involve some degree of sorting and temporary storage, Dynamic Cross-docking optimizes real-time inventory flow and enhances supply chain responsiveness through synchronized scheduling and integrated communication systems.

Synchronized Flow-through

Synchronized flow-through centers optimize warehousing efficiency by seamlessly integrating inbound and outbound logistics, minimizing storage time and reducing handling costs compared to traditional cross-docking. This method enhances inventory turnover and accelerates order fulfillment by coordinating the flow of goods in real-time across multiple supply chain nodes.

Pre-distribution Sorting

Cross-docking involves minimal handling where goods are directly transferred from inbound to outbound transportation, optimizing pre-distribution sorting by reducing storage time and expediting order fulfillment. Flow-through centers integrate pre-distribution sorting with light storage, enabling efficient inventory management and customization of shipments before final dispatch.

Hybrid Dock Operations

Hybrid dock operations combine cross-docking and flow-through center strategies to optimize warehousing efficiency by enabling rapid sorting and direct shipment while accommodating temporary storage when necessary. This approach reduces handling time and inventory holding costs, leveraging synchronized inbound and outbound processes to streamline supply chain flow.

Flow-driven Fulfillment

Flow-through centers optimize order fulfillment by directly transferring inbound goods to outbound shipments with minimal storage, reducing lead times and inventory costs. Cross-docking emphasizes rapid sorting and distribution of products, but flow-driven fulfillment centers integrate real-time demand data to synchronize inventory flow and improve supply chain responsiveness.

Just-in-Time Transshipment

Cross-docking minimizes inventory holding by directly transferring goods from inbound to outbound trucks, supporting Just-in-Time transshipment with faster throughput and reduced storage costs. Flow-through centers enhance operational efficiency by adding light processing while maintaining rapid flow, facilitating Just-in-Time delivery with controlled handling and improved order accuracy.

Forward-Flow Staging

Forward-flow staging in cross-docking streamlines inventory movement by immediately transferring incoming goods to outbound transportation, minimizing storage time and reducing handling costs. In contrast, flow-through centers incorporate short-term inventory holding, enabling more flexible order consolidation and improved demand responsiveness while still aiming to accelerate product throughput.

Direct-to-Store Flow

Cross-docking streamlines direct-to-store flow by rapidly transferring inbound goods to outbound transportation with minimal storage, reducing handling time and inventory costs. Flow-through centers combine limited storage with picking and sorting activities, offering flexibility for demand variability while maintaining efficient direct shipments to retail locations.

Live Unloading

Cross-docking minimizes storage by transferring inbound shipments directly to outbound transport, enabling live unloading that accelerates product flow and reduces handling time. Flow-through centers combine cross-docking with limited storage, using live unloading to quickly process and temporarily stage goods before final distribution.

Segmented Flow Pathways

Cross-docking utilizes segmented flow pathways by rapidly transferring goods from inbound to outbound transportation with minimal storage, optimizing turnaround time and reducing handling costs. In contrast, flow-through centers incorporate segmented pathways that combine temporary storage and sorting, enhancing inventory control while maintaining efficient product movement within the warehouse.

Cross-docking vs Flow-through Center Infographic

industrydif.com

industrydif.com