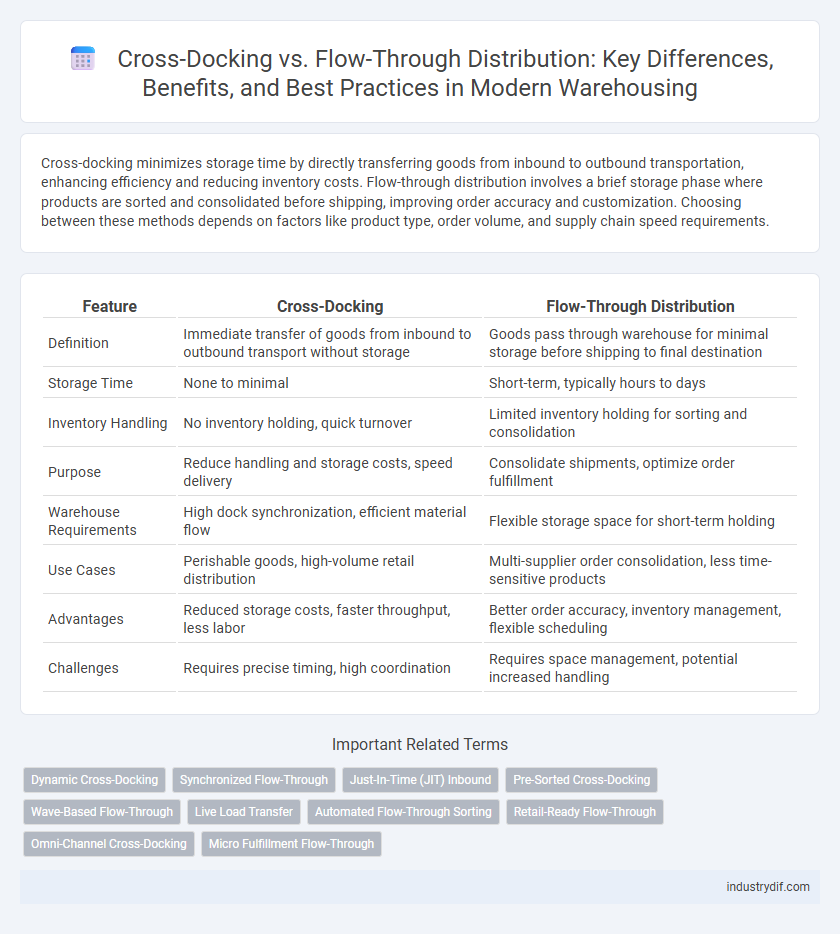

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, enhancing efficiency and reducing inventory costs. Flow-through distribution involves a brief storage phase where products are sorted and consolidated before shipping, improving order accuracy and customization. Choosing between these methods depends on factors like product type, order volume, and supply chain speed requirements.

Table of Comparison

| Feature | Cross-Docking | Flow-Through Distribution |

|---|---|---|

| Definition | Immediate transfer of goods from inbound to outbound transport without storage | Goods pass through warehouse for minimal storage before shipping to final destination |

| Storage Time | None to minimal | Short-term, typically hours to days |

| Inventory Handling | No inventory holding, quick turnover | Limited inventory holding for sorting and consolidation |

| Purpose | Reduce handling and storage costs, speed delivery | Consolidate shipments, optimize order fulfillment |

| Warehouse Requirements | High dock synchronization, efficient material flow | Flexible storage space for short-term holding |

| Use Cases | Perishable goods, high-volume retail distribution | Multi-supplier order consolidation, less time-sensitive products |

| Advantages | Reduced storage costs, faster throughput, less labor | Better order accuracy, inventory management, flexible scheduling |

| Challenges | Requires precise timing, high coordination | Requires space management, potential increased handling |

Introduction to Cross-Docking and Flow-Through Distribution

Cross-docking is a logistics strategy where incoming goods are directly transferred from inbound to outbound transportation with minimal or no storage, optimizing inventory turnover and reducing warehousing costs. Flow-through distribution involves products moving through a distribution center with minimal handling and inventory holding, enabling rapid order fulfillment and streamlined supply chain operations. Both methods enhance efficiency by minimizing storage time, but cross-docking emphasizes direct transfer while flow-through integrates order processing within the facility.

Key Differences Between Cross-Docking and Flow-Through Distribution

Cross-Docking involves the immediate transfer of goods from inbound to outbound transportation with minimal storage, optimizing speed and reducing inventory holding costs. Flow-Through Distribution integrates receiving, sorting, and shipping processes within the warehouse, allowing for light storage and order consolidation before dispatch. Key differences include cross-docking's emphasis on rapid throughput and minimal handling, whereas flow-through supports more complex order customization and moderate inventory buffering.

How Cross-Docking Works in Warehousing

Cross-docking in warehousing involves the immediate transfer of inbound goods directly to outbound transportation with minimal or no storage time. This process reduces inventory holding costs by streamlining material flow through staging areas where products are sorted and consolidated based on destination. Efficient cross-docking requires synchronized logistics management and real-time communication to ensure timely unloading, sorting, and loading, optimizing overall supply chain velocity.

Flow-Through Distribution: Process and Benefits

Flow-through distribution streamlines warehouse operations by directly transferring incoming goods to outbound trucks without long-term storage, minimizing handling time and reducing inventory holding costs. This process enhances supply chain efficiency by accelerating order fulfillment and improving shipment accuracy through real-time inventory updates. Companies adopting flow-through distribution benefit from lowered operational expenses and increased responsiveness to market demand fluctuations.

Inventory Management Strategies in Cross-Docking vs Flow-Through

Cross-docking minimizes inventory holding by transferring goods directly from inbound to outbound transportation, reducing storage time and improving turnover rates. Flow-through distribution involves short-term storage, allowing for consolidation or customization before shipping, which requires more sophisticated inventory tracking and space management. Inventory management strategies in cross-docking prioritize rapid flow and real-time stock visibility, while flow-through demands integration of warehouse management systems to handle temporary inventory buffering and order fulfillment.

Impact on Supply Chain Efficiency

Cross-docking minimizes storage time by directly transferring inbound goods to outbound transportation, significantly reducing handling costs and accelerating order fulfillment in the supply chain. Flow-through distribution streamlines inventory management by bypassing traditional warehousing, enabling faster processing of high-demand products and improving overall throughput. Both strategies enhance supply chain efficiency by reducing lead times, lowering inventory carrying costs, and increasing responsiveness to market fluctuations.

Technology and Automation in Cross-Docking vs Flow-Through

Cross-docking leverages advanced automation technologies such as conveyor systems, automated sorting, and real-time tracking software to minimize handling time and streamline product flow directly from inbound to outbound shipments. Flow-through distribution integrates warehouse management systems (WMS) and automated picking solutions to facilitate seamless inventory flow with minimal storage, improving accuracy and reducing labor costs. Both methods utilize robotics and data analytics, but cross-docking emphasizes speed and synchronization, while flow-through focuses on inventory visibility and optimal order fulfillment.

Industry Applications and Use Cases

Cross-docking is widely utilized in retail and perishable goods industries to minimize storage time and speed up order fulfillment by directly transferring products from inbound to outbound transportation. Flow-through distribution is favored in e-commerce and manufacturing sectors where inventory sorting, packaging, and customization are necessary before final shipment. Both methods enhance supply chain efficiency but cater to different operational requirements based on product type and order complexity.

Challenges and Risk Factors

Cross-docking faces challenges such as tight scheduling demands, high dependency on carrier reliability, and limited buffer capacity, which increase risks of delays and inventory inaccuracies. Flow-through distribution systems encounter risks related to complex sorting processes, inventory misallocation, and increased handling errors due to simultaneous receiving and shipping operations. Both methods require advanced technology integration and real-time data management to mitigate operational inefficiencies and ensure supply chain continuity.

Choosing the Right Model: Factors for Decision-Making

Selecting between cross-docking and flow-through distribution depends on factors such as inventory turnover rates, product shelf life, and order variability. Cross-docking suits high-volume, time-sensitive goods requiring minimal storage, while flow-through distribution accommodates products needing quality checks or customization before shipment. Assessing warehouse capacity, transportation schedules, and customer delivery requirements ensures optimal model alignment with operational efficiency and cost reduction goals.

Related Important Terms

Dynamic Cross-Docking

Dynamic Cross-Docking streamlines warehouse operations by directly transferring incoming goods to outbound transportation without storage, enhancing throughput and reducing inventory holding costs compared to traditional flow-through distribution. This method leverages real-time data integration and advanced scheduling algorithms to optimize dock door assignments and minimize handling time, significantly improving supply chain responsiveness.

Synchronized Flow-Through

Synchronized Flow-Through distribution optimizes inventory handling by seamlessly integrating inbound and outbound shipments, reducing storage time and increasing throughput efficiency in warehouses. This method contrasts with traditional Cross-Docking by enabling better coordination of product flow, minimizing bottlenecks, and enhancing real-time inventory visibility for faster order fulfillment.

Just-In-Time (JIT) Inbound

Cross-docking enables Just-In-Time (JIT) inbound operations by minimizing storage time and streamlining direct transfer of goods from inbound to outbound transportation, enhancing inventory turnover and reducing handling costs. Flow-through distribution supports JIT by allowing products to bypass traditional warehousing stages, improving supply chain responsiveness and reducing lead times through synchronized inbound and outbound processes.

Pre-Sorted Cross-Docking

Pre-Sorted Cross-Docking streamlines warehousing by receiving inbound shipments already sorted by destination, minimizing handling time and reducing storage requirements compared to traditional flow-through distribution. This method enhances operational efficiency by accelerating product flow from suppliers to customers, lowering labor costs, and improving inventory turnover rates.

Wave-Based Flow-Through

Wave-based flow-through distribution optimizes warehouse operations by grouping orders into waves, allowing simultaneous loading and unloading that reduces handling time and improves order accuracy. Unlike cross-docking, which immediately transfers incoming goods to outbound shipments, wave-based flow-through balances inventory flow with order consolidation, enhancing overall throughput and minimizing storage needs.

Live Load Transfer

Live Load Transfer in Cross-Docking minimizes storage time by directly moving inbound goods to outbound transportation, enhancing throughput efficiency and reducing handling costs. In contrast, Flow-Through Distribution temporarily stages products in a warehouse, allowing for sorting and order consolidation before dispatch, which increases flexibility but adds dwell time and inventory holding expenses.

Automated Flow-Through Sorting

Automated flow-through sorting in warehousing enhances efficiency by directly routing products from inbound to outbound shipments with minimal handling, reducing storage time and labor costs. This system contrasts with cross-docking by emphasizing continuous, automated sorting processes that optimize order fulfillment speed and accuracy through integrated conveyor belts and real-time inventory tracking.

Retail-Ready Flow-Through

Retail-ready flow-through distribution streamlines the supply chain by enabling products to bypass traditional storage, directly moving from receiving to shipping docks with minimal handling. This method reduces inventory carrying costs and accelerates shelf replenishment, optimizing efficiency for high-demand retail environments.

Omni-Channel Cross-Docking

Omni-channel cross-docking streamlines inventory flow by directly transferring products from inbound to outbound transportation without storage, reducing handling time and costs. This method contrasts with flow-through distribution, where goods are temporarily stored and consolidated before shipment, potentially increasing lead times and inventory holding expenses.

Micro Fulfillment Flow-Through

Micro fulfillment flow-through optimizes warehousing by combining the efficiency of cross-docking with rapid order processing, minimizing storage time and enhancing last-mile delivery speed. This model leverages compact, automated micro-fulfillment centers within urban areas, enabling direct flow-through distribution that reduces transit times and operational costs.

Cross-Docking vs Flow-Through Distribution Infographic

industrydif.com

industrydif.com