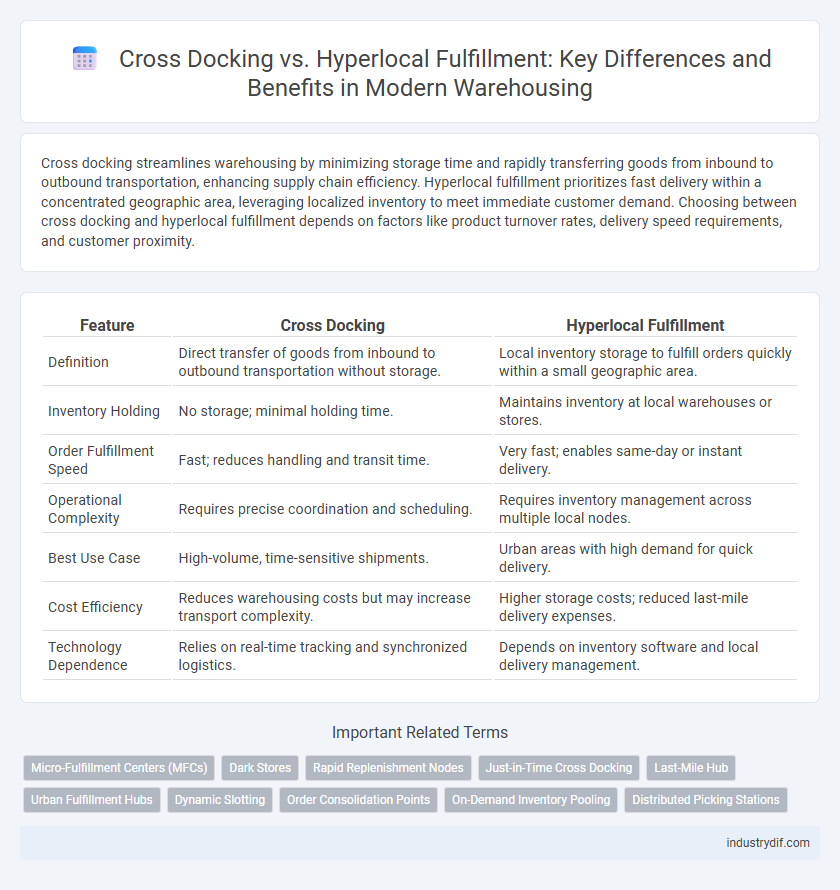

Cross docking streamlines warehousing by minimizing storage time and rapidly transferring goods from inbound to outbound transportation, enhancing supply chain efficiency. Hyperlocal fulfillment prioritizes fast delivery within a concentrated geographic area, leveraging localized inventory to meet immediate customer demand. Choosing between cross docking and hyperlocal fulfillment depends on factors like product turnover rates, delivery speed requirements, and customer proximity.

Table of Comparison

| Feature | Cross Docking | Hyperlocal Fulfillment |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound transportation without storage. | Local inventory storage to fulfill orders quickly within a small geographic area. |

| Inventory Holding | No storage; minimal holding time. | Maintains inventory at local warehouses or stores. |

| Order Fulfillment Speed | Fast; reduces handling and transit time. | Very fast; enables same-day or instant delivery. |

| Operational Complexity | Requires precise coordination and scheduling. | Requires inventory management across multiple local nodes. |

| Best Use Case | High-volume, time-sensitive shipments. | Urban areas with high demand for quick delivery. |

| Cost Efficiency | Reduces warehousing costs but may increase transport complexity. | Higher storage costs; reduced last-mile delivery expenses. |

| Technology Dependence | Relies on real-time tracking and synchronized logistics. | Depends on inventory software and local delivery management. |

Understanding Cross Docking in Modern Warehousing

Cross docking in modern warehousing streamlines inventory flow by directly transferring goods from inbound to outbound transportation, minimizing storage time and reducing handling costs. This method enhances supply chain efficiency by accelerating order fulfillment and decreasing warehouse space requirements. Compared to hyperlocal fulfillment, which prioritizes quick delivery from nearby inventory hubs, cross docking is ideal for high-volume, time-sensitive shipments that demand rapid turnover.

What Is Hyperlocal Fulfillment?

Hyperlocal fulfillment refers to a warehousing strategy that emphasizes delivering products within a very short radius, often within a few miles, to meet immediate customer demand rapidly. Utilizing localized inventory hubs, this approach reduces delivery times drastically, supporting same-day or even hour-based shipping windows. Businesses implement hyperlocal fulfillment to enhance customer experience by leveraging real-time inventory management and proximity-based distribution.

Key Differences Between Cross Docking and Hyperlocal Fulfillment

Cross docking streamlines supply chain efficiency by directly transferring goods from inbound to outbound transportation without long-term storage, reducing inventory holding costs and delivery time for bulk shipments. Hyperlocal fulfillment focuses on rapid delivery within a small geographic area, leveraging neighborhood warehouses or retail stores to meet same-day or next-hour customer demands. Key differences include cross docking's emphasis on minimizing storage and handling in centralized distribution centers versus hyperlocal fulfillment's reliance on decentralized inventory placement to enable ultra-fast delivery.

Benefits of Cross Docking for Supply Chain Efficiency

Cross docking significantly reduces inventory holding costs by enabling direct transfer of goods from inbound to outbound transportation, minimizing storage time. This process accelerates order fulfillment and enhances supply chain responsiveness by streamlining product flow through distribution centers. By improving inventory turnover and reducing handling, cross docking optimizes warehouse operations and supports just-in-time delivery strategies.

Advantages of Hyperlocal Fulfillment in E-Commerce

Hyperlocal fulfillment in e-commerce offers significant advantages including faster delivery times by leveraging local inventory storage, which enhances customer satisfaction and loyalty. This approach reduces transportation costs and carbon emissions by minimizing the distance between warehouses and end consumers. Hyperlocal fulfillment also improves inventory accuracy and demand forecasting through localized data, allowing retailers to respond swiftly to market trends and customer preferences.

Inventory Management: Cross Docking vs Hyperlocal Fulfillment

Cross docking minimizes inventory holding by swiftly transferring goods directly from inbound to outbound transportation, reducing storage costs and enhancing order throughput. Hyperlocal fulfillment requires maintaining a distributed inventory across multiple local hubs to ensure rapid delivery, prioritizing stock accuracy and real-time inventory tracking. Effective inventory management in cross docking emphasizes velocity and turnover, whereas hyperlocal fulfillment focuses on availability and proximity to consumer demand centers.

Delivery Speed: Which Model is Faster?

Cross docking significantly reduces delivery speed by minimizing storage time, as goods are directly transferred from inbound to outbound transportation. Hyperlocal fulfillment enhances last-mile delivery speed by sourcing products from nearby warehouses or stores, ensuring rapid delivery within hours. While cross docking optimizes supply chain efficiency for regional deliveries, hyperlocal fulfillment outpaces it with ultra-fast delivery in local markets.

Cost Implications of Cross Docking and Hyperlocal Fulfillment

Cross docking reduces warehousing costs by minimizing storage time and handling expenses, leading to faster inventory turnover and lower labor requirements. Hyperlocal fulfillment incurs higher costs due to the need for multiple micro-fulfillment centers, increased last-mile delivery expenses, and sophisticated inventory management systems to meet rapid delivery expectations. Businesses must weigh cross docking's efficiency in bulk shipments against hyperlocal's premium costs for speed and proximity to customers.

Technology’s Role in Cross Docking and Hyperlocal Operations

Technology enhances cross docking by streamlining inventory management through real-time tracking systems and automated sorting, minimizing storage time and accelerating shipment processing. In hyperlocal fulfillment, advanced algorithms optimize route planning and demand forecasting to ensure rapid, accurate delivery within limited geographical areas. Integration of IoT devices and AI-driven analytics enables both operations to reduce costs, improve efficiency, and meet evolving customer expectations.

Choosing the Right Fulfillment Strategy for Your Business

Cross docking reduces inventory holding costs by moving products directly from inbound to outbound shipping, ideal for high-volume, low-variation items requiring fast turnover. Hyperlocal fulfillment leverages localized warehouses or stores to expedite last-mile delivery, enhancing customer satisfaction for time-sensitive orders in dense urban areas. Selecting the right strategy depends on factors such as order volume, delivery speed requirements, geographic reach, and product type to optimize operational efficiency and customer experience.

Related Important Terms

Micro-Fulfillment Centers (MFCs)

Micro-Fulfillment Centers (MFCs) enable hyperlocal fulfillment by utilizing automated, compact warehouses near urban areas for rapid, last-mile delivery, contrasting with cross docking which primarily focuses on fast transfer of goods between trucks without long-term storage. MFCs optimize inventory management and reduce delivery times by storing products close to consumers, supporting e-commerce growth through localized, efficient order processing.

Dark Stores

Dark stores serve as pivotal hubs in hyperlocal fulfillment by enabling swift, last-mile delivery through localized inventory storage, contrasting with cross docking's emphasis on minimizing storage by directly transferring goods between inbound and outbound transportation. Leveraging dark stores enhances order accuracy and reduces delivery times in hyperlocal fulfillment, whereas cross docking optimizes supply chain efficiency by streamlining product flow without prolonged storage.

Rapid Replenishment Nodes

Cross docking streamlines operations by transferring goods directly from inbound to outbound transportation, minimizing storage time and accelerating order fulfillment. Hyperlocal fulfillment leverages rapid replenishment nodes strategically located near demand centers to enable same-day delivery and enhance last-mile efficiency.

Just-in-Time Cross Docking

Just-in-Time Cross Docking streamlines warehousing operations by transferring goods directly from inbound to outbound transportation with minimal storage, reducing inventory holding costs and accelerating delivery times. This method contrasts with Hyperlocal Fulfillment, which emphasizes rapid order fulfillment within nearby distribution centers to meet immediate consumer demand in urban areas.

Last-Mile Hub

Cross docking minimizes storage by directly transferring goods from inbound to outbound transportation, streamlining inventory flow at last-mile hubs and reducing delivery times. Hyperlocal fulfillment leverages decentralized last-mile hubs positioned near end customers to enable rapid order processing and same-day delivery, optimizing customer satisfaction in urban environments.

Urban Fulfillment Hubs

Urban fulfillment hubs leverage cross docking to minimize inventory holding time by rapidly transferring goods from inbound to outbound transportation, enhancing delivery speed in dense city areas. In contrast, hyperlocal fulfillment focuses on storing small, curated inventories within these hubs to enable immediate order processing and last-mile delivery, catering to real-time consumer demand in urban environments.

Dynamic Slotting

Dynamic slotting enhances both cross docking and hyperlocal fulfillment by optimizing inventory placement in real-time, reducing handling times and accelerating order processing. In cross docking, this strategy facilitates swift transfer of goods directly from inbound to outbound shipments, while in hyperlocal fulfillment, it supports rapid, accurate order assembly to meet local delivery demands efficiently.

Order Consolidation Points

Cross docking streamlines logistics by rapidly transferring goods from inbound to outbound transportation with minimal storage time, enhancing order consolidation through centralized sorting hubs. Hyperlocal fulfillment prioritizes proximity-based order consolidation points, enabling faster last-mile delivery by aggregating inventory closer to end consumers within localized distribution centers.

On-Demand Inventory Pooling

Cross docking streamlines on-demand inventory pooling by rapidly transferring products directly from inbound to outbound transportation, minimizing storage time and accelerating order fulfillment in warehousing. Hyperlocal fulfillment enhances this approach by leveraging distributed micro-warehouses near end customers, optimizing inventory allocation, and reducing delivery lead times for immediate demand response.

Distributed Picking Stations

Distributed picking stations in cross docking streamline the rapid transfer of goods by minimizing storage time and reducing handling costs, enhancing overall supply chain efficiency. In hyperlocal fulfillment, these stations enable localized inventory management and faster order processing, improving delivery speed and customer satisfaction in densely populated areas.

Cross Docking vs Hyperlocal Fulfillment Infographic

industrydif.com

industrydif.com