Warehouse automation streamlines material handling and inventory management through robotics and automated systems, reducing labor costs and improving operational efficiency. A warehouse digital twin offers a virtual replica of the warehouse environment, enabling real-time monitoring, predictive analytics, and scenario planning for better decision-making. Combining automation with a digital twin enhances overall warehouse performance by integrating physical processes with digital insights for optimized workflow and resource allocation.

Table of Comparison

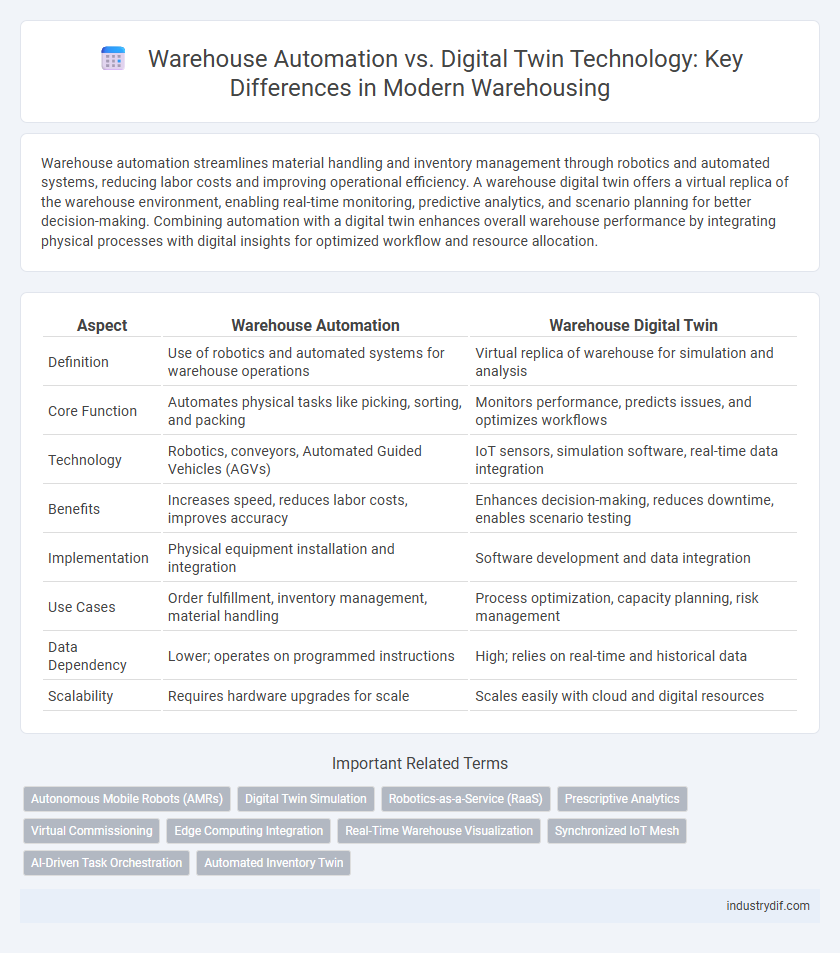

| Aspect | Warehouse Automation | Warehouse Digital Twin |

|---|---|---|

| Definition | Use of robotics and automated systems for warehouse operations | Virtual replica of warehouse for simulation and analysis |

| Core Function | Automates physical tasks like picking, sorting, and packing | Monitors performance, predicts issues, and optimizes workflows |

| Technology | Robotics, conveyors, Automated Guided Vehicles (AGVs) | IoT sensors, simulation software, real-time data integration |

| Benefits | Increases speed, reduces labor costs, improves accuracy | Enhances decision-making, reduces downtime, enables scenario testing |

| Implementation | Physical equipment installation and integration | Software development and data integration |

| Use Cases | Order fulfillment, inventory management, material handling | Process optimization, capacity planning, risk management |

| Data Dependency | Lower; operates on programmed instructions | High; relies on real-time and historical data |

| Scalability | Requires hardware upgrades for scale | Scales easily with cloud and digital resources |

Introduction to Warehouse Automation and Digital Twin

Warehouse automation integrates advanced robotics, automated storage and retrieval systems (AS/RS), and IoT sensors to enhance efficiency, accuracy, and throughput in material handling operations. Digital twin technology creates a virtual replica of the physical warehouse environment, enabling real-time simulation, monitoring, and predictive analytics to optimize workflows and asset utilization. Combining automation with digital twins drives intelligent decision-making, reduces downtime, and improves overall supply chain responsiveness.

Core Definitions: Automation vs Digital Twin

Warehouse automation involves the use of robotics, conveyor systems, and automated storage and retrieval systems to streamline physical tasks such as picking, packing, and transporting goods. A warehouse digital twin is a virtual replica of the physical warehouse environment, enabling real-time monitoring, simulation, and optimization of warehouse operations through data integration and advanced analytics. While automation focuses on executing tasks through machinery, digital twins emphasize predictive insights and decision-making by mirroring warehouse processes digitally.

Key Technologies Powering Warehouse Automation

Key technologies powering warehouse automation include robotics, autonomous guided vehicles (AGVs), and conveyor systems, which streamline material handling and order fulfillment. Advanced sensors, IoT devices, and machine learning algorithms enable real-time inventory management and predictive maintenance. In contrast, warehouse digital twins leverage 3D simulation, data analytics, and virtual reality to create a dynamic replica of warehouse operations for optimization and decision-making.

Essential Components of Warehouse Digital Twins

Warehouse digital twins rely on essential components such as real-time data integration, 3D modeling, and advanced analytics to create a virtual replica of the physical warehouse environment. Unlike traditional warehouse automation that focuses on mechanizing tasks, digital twins provide continuous monitoring, simulation, and predictive insights to optimize operations. Key elements include IoT sensors for live data capture, cloud platforms for data processing, and AI algorithms for scenario testing and decision-making.

Operational Benefits: Automation vs Digital Twin

Warehouse automation enhances operational efficiency by streamlining material handling and reducing human error through robotics and automated systems. Warehouse digital twins offer real-time simulation and predictive analytics, enabling proactive decision-making and optimization of warehouse layout and workflows. Combining automation with digital twins maximizes throughput, minimizes downtime, and improves inventory accuracy in complex supply chains.

Impact on Inventory Management

Warehouse automation streamlines inventory management by reducing manual errors and increasing efficiency through robotics and automated systems. Warehouse digital twins enhance inventory accuracy by providing real-time simulations and predictive analytics, enabling proactive decision-making. Combining automation with digital twin technology further optimizes stock control, minimizes stockouts, and improves overall supply chain responsiveness.

Integration and Scalability in Modern Warehousing

Warehouse automation streamlines physical operations by integrating robotics, conveyor systems, and sensors to enhance efficiency and reduce human error. Warehouse digital twins create virtual replicas of warehouse environments, enabling data-driven analytics and predictive simulations to optimize workflows and resource allocation. Combining automation with digital twin technology offers scalable solutions that adapt to evolving inventory demands and operational complexities in modern warehousing.

Real-Time Data Utilization: Contrasting Approaches

Warehouse automation streamlines physical processes through robotics and automated equipment, optimizing tasks like sorting and inventory movement with real-time sensor data. Warehouse digital twins create virtual replicas of facilities, leveraging real-time data integration from IoT devices and ERP systems to simulate operations and predict outcomes. The automation focuses on executing actions based on immediate data, while digital twins emphasize analysis and decision-making through comprehensive real-time data modeling.

Cost Implications and ROI Analysis

Warehouse automation involves implementing robotic systems and automated processes to reduce labor costs and increase operational efficiency, resulting in significant upfront capital expenditure but faster ROI through labor savings. In contrast, warehouse digital twins create virtual replicas of the facility to optimize layout, workflows, and resource allocation, requiring investment in software and sensors but providing continuous improvement insights that enhance long-term cost-efficiency. ROI analysis shows automation delivers immediate operational cost reductions, while digital twins generate ongoing value by minimizing waste and improving decision-making accuracy.

Future Trends: Merging Automation with Digital Twins

Future trends in warehousing highlight the integration of warehouse automation systems with advanced digital twin technology to enhance operational efficiency. Digital twins provide real-time simulation and data analytics, enabling predictive maintenance and dynamic workflow optimization in automated warehouses. This fusion accelerates decision-making processes and drives smarter, more adaptive supply chain management strategies.

Related Important Terms

Autonomous Mobile Robots (AMRs)

Warehouse automation leverages Autonomous Mobile Robots (AMRs) to optimize material handling and increase operational efficiency by enabling real-time navigation and task execution without human intervention. In contrast, a warehouse digital twin integrates AMRs within a virtual replica of the physical warehouse, facilitating advanced simulation, predictive analytics, and strategic decision-making to enhance automation workflows and resource allocation.

Digital Twin Simulation

Warehouse digital twins leverage simulation technology to create dynamic, real-time virtual replicas of physical warehouse operations, enabling predictive analytics and process optimization. Unlike traditional warehouse automation that focuses on mechanization and robotics, digital twin simulation provides comprehensive insights into workflow efficiency, inventory management, and spatial utilization, driving smarter decision-making and operational agility.

Robotics-as-a-Service (RaaS)

Warehouse automation leverages Robotics-as-a-Service (RaaS) to deploy scalable and flexible robotic systems that streamline material handling, sorting, and inventory management without heavy upfront investment. In contrast, warehouse digital twin technology integrates RaaS within a virtual replica of the facility, enabling real-time simulation and optimization of robotic workflows to enhance operational efficiency and reduce downtime.

Prescriptive Analytics

Warehouse automation streamlines operations through robotics and AI, while warehouse digital twins use prescriptive analytics to simulate and optimize workflows by predicting outcomes and recommending actions. Leveraging prescriptive analytics, digital twins enhance decision-making accuracy, reduce costs, and improve efficiency beyond traditional automation capabilities.

Virtual Commissioning

Warehouse automation enhances operational efficiency by integrating robotics and IoT devices to streamline inventory handling and reduce labor costs. Warehouse digital twins leverage virtual commissioning to simulate and optimize automated systems before physical deployment, minimizing errors and accelerating project timelines.

Edge Computing Integration

Warehouse automation leverages edge computing integration to process data locally from IoT devices and robotics, minimizing latency and enhancing real-time decision-making on inventory management and order fulfillment. Warehouse digital twins incorporate edge computing to create dynamic virtual replicas, enabling continuous synchronization with physical assets for predictive maintenance and optimized operational efficiency.

Real-Time Warehouse Visualization

Warehouse automation enhances operational efficiency through robotics and automated systems, while warehouse digital twins provide real-time warehouse visualization by creating a dynamic virtual replica of physical assets. This digital twin technology enables continuous monitoring, predictive analytics, and optimized decision-making for inventory management and workflow improvements.

Synchronized IoT Mesh

Synchronized IoT Mesh networks in warehouse automation enable real-time data exchange between autonomous robots, inventory systems, and environmental sensors, enhancing operational efficiency and accuracy. Warehouse digital twins leverage the same IoT mesh infrastructure to create dynamic, virtual replicas of physical assets, allowing predictive analytics and seamless synchronization of digital and physical workflows.

AI-Driven Task Orchestration

AI-driven task orchestration in warehouse automation leverages robotics and machine learning to optimize real-time operations, reduce human error, and accelerate order fulfillment. In contrast, warehouse digital twins provide a dynamic, high-fidelity virtual replica of physical assets, enabling predictive analytics and scenario planning that enhance decision-making efficiency and operational resilience.

Automated Inventory Twin

Automated Inventory Twin leverages advanced sensors and real-time data integration to create an exact digital replica of warehouse stock, enhancing accuracy and operational efficiency beyond traditional warehouse automation systems. This digital twin enables predictive inventory management and dynamic resource allocation, reducing errors and downtime while optimizing warehouse workflows.

Warehouse automation vs Warehouse digital twin Infographic

industrydif.com

industrydif.com