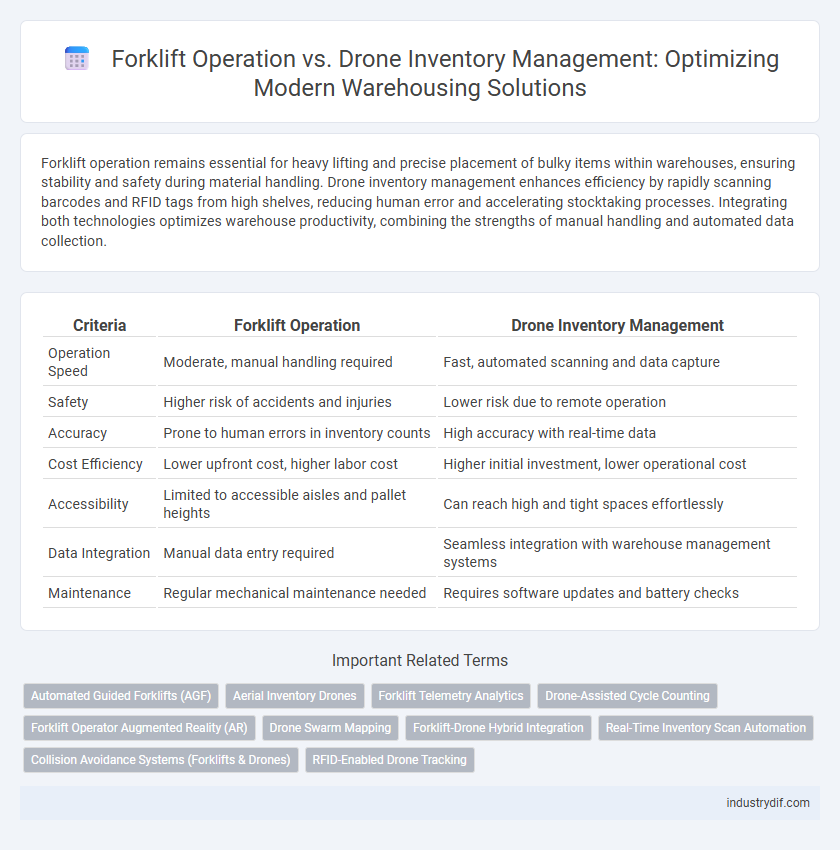

Forklift operation remains essential for heavy lifting and precise placement of bulky items within warehouses, ensuring stability and safety during material handling. Drone inventory management enhances efficiency by rapidly scanning barcodes and RFID tags from high shelves, reducing human error and accelerating stocktaking processes. Integrating both technologies optimizes warehouse productivity, combining the strengths of manual handling and automated data collection.

Table of Comparison

| Criteria | Forklift Operation | Drone Inventory Management |

|---|---|---|

| Operation Speed | Moderate, manual handling required | Fast, automated scanning and data capture |

| Safety | Higher risk of accidents and injuries | Lower risk due to remote operation |

| Accuracy | Prone to human errors in inventory counts | High accuracy with real-time data |

| Cost Efficiency | Lower upfront cost, higher labor cost | Higher initial investment, lower operational cost |

| Accessibility | Limited to accessible aisles and pallet heights | Can reach high and tight spaces effortlessly |

| Data Integration | Manual data entry required | Seamless integration with warehouse management systems |

| Maintenance | Regular mechanical maintenance needed | Requires software updates and battery checks |

Introduction to Warehouse Automation

Warehouse automation enhances efficiency by integrating advanced technologies like forklift operation and drone inventory management. Forklift operation remains essential for heavy lifting and material transport, while drones offer rapid, real-time inventory tracking and improved accuracy. Combining these technologies optimizes warehouse workflows, reduces labor costs, and minimizes human error.

Overview of Forklift Operations

Forklift operations in warehousing involve the use of powered industrial trucks to lift, move, and stack heavy materials efficiently on pallets and shelving units. Operators require specialized training and certification to ensure safe handling, precise maneuvering in tight spaces, and adherence to safety protocols. This traditional method remains essential for handling bulky or heavy inventory that drones cannot manage, maintaining high productivity in large storage facilities.

Drone Technology in Inventory Management

Drone technology in inventory management revolutionizes warehousing by enabling rapid, accurate stocktaking and real-time data collection, significantly reducing human error and labor costs. Equipped with high-resolution cameras and RFID scanners, drones can efficiently navigate large warehouses, capturing precise inventory information in hard-to-reach areas. This integration enhances operational efficiency, accelerates inventory cycles, and supports advanced analytics for better supply chain decision-making.

Efficiency Comparison: Forklifts vs Drones

Forklift operation enables efficient heavy-load handling and precise placement within warehouse aisles, maintaining high productivity for bulk inventory movement. Drone inventory management offers rapid stocktaking capabilities, accessing hard-to-reach areas and providing real-time data updates with minimal labor involvement. Comparing efficiency, forklifts excel in physical transport and load handling, while drones optimize inventory accuracy and expedite auditing processes through automated scanning technologies.

Safety Considerations for Each Method

Forklift operation requires strict adherence to safety protocols such as operator training, regular equipment maintenance, and clear warehouse traffic management to prevent accidents and injuries. Drone inventory management minimizes physical hazards by reducing human presence in high shelves, but it demands rigorous compliance with airspace regulations, collision avoidance systems, and remote operation training. Both methods emphasize safety, with forklifts focusing on mechanical risk mitigation and drones prioritizing electronic system reliability and operational control.

Cost Analysis: Traditional vs Modern Solutions

Forklift operation in warehousing involves significant costs including fuel, maintenance, and labor wages, typically averaging $25,000 to $40,000 annually per unit. In contrast, drone inventory management reduces operational expenses by minimizing manual labor and enhancing inventory accuracy, with initial investments ranging from $10,000 to $15,000 per drone plus software. Modern drone solutions offer scalable savings by cutting labor hours by up to 70% and decreasing inventory errors by 50%, making them cost-effective compared to traditional forklift-dependent systems.

Impact on Labor and Workforce Roles

Forklift operation demands skilled operators trained in vehicle handling, directly involving manual labor and increasing physical strain on warehouse staff. Drone inventory management automates stocktaking processes, reducing reliance on human labor and shifting workforce roles toward tech maintenance and data analysis. This technological transition can lead to labor cost savings and reprioritize employee responsibilities from manual tasks to higher-skilled operational oversight.

Scalability and Integration Challenges

Forklift operation offers proven scalability in warehousing but faces limitations in complex or high-density environments, requiring significant manpower and safety protocols. Drone inventory management demonstrates high scalability through rapid data collection and automation but encounters integration challenges with existing warehouse management systems and regulatory compliance. Balancing these technologies involves addressing technological interoperability and operational workflows to optimize scalability and efficiency.

Case Studies: Industry Adoption

Case studies reveal that forklift operation remains dominant in traditional warehousing sectors such as automotive and manufacturing due to its robustness in heavy-lifting tasks. Drone inventory management has gained traction in e-commerce and pharmaceutical warehouses by enhancing real-time inventory tracking and reducing labor costs. Companies like Amazon and DHL report improved accuracy and operational efficiency after integrating drones alongside forklift operations.

Future Trends in Warehouse Management

Forklift operation remains essential for heavy lifting and pallet movement, but drone inventory management is rapidly transforming warehouse efficiency through real-time data capture and automated stocktaking. Future trends emphasize integrating drones with AI-powered systems to enhance accuracy, reduce labor costs, and improve safety by minimizing human exposure to hazardous environments. Advanced warehouse management systems (WMS) will increasingly leverage drone technology alongside traditional forklifts to optimize inventory control and streamline logistics workflows.

Related Important Terms

Automated Guided Forklifts (AGF)

Automated Guided Forklifts (AGF) enhance warehouse efficiency by combining precision navigation and heavy-load handling, outperforming traditional forklift operation in speed and safety. Compared to drone inventory management, AGFs excel in transporting bulky goods across varied terrain, making them indispensable for large-scale warehousing logistics.

Aerial Inventory Drones

Aerial inventory drones offer significant efficiency improvements over traditional forklift operation by providing rapid, automated stock counting and real-time data accuracy in large warehouses. These drones reduce labor costs and improve safety by minimizing the need for manual inventory checks at high elevations.

Forklift Telemetry Analytics

Forklift telemetry analytics enhances warehouse efficiency by providing real-time data on forklift utilization, maintenance needs, and operator behavior, reducing downtime and improving safety. Compared to drone inventory management, forklift telemetry offers more precise insights into ground-level operations, optimizing material handling and streamlining workflow management.

Drone-Assisted Cycle Counting

Drone-assisted cycle counting in warehousing significantly enhances inventory accuracy by rapidly scanning and verifying stock levels across large storage areas, reducing human error common in forklift operation. This technology streamlines data collection through automated aerial surveys, improving efficiency and safety while minimizing labor costs associated with traditional forklift-based inventory management.

Forklift Operator Augmented Reality (AR)

Forklift Operator Augmented Reality (AR) enhances warehouse efficiency by overlaying real-time data and navigation cues directly onto the operator's field of view, improving accuracy in picking and reducing handling errors compared to traditional forklift operation. This integration supports seamless inventory management workflows by enabling faster load identification and safer material transport, surpassing drone inventory management in direct load handling and complex pallet movement tasks.

Drone Swarm Mapping

Drone swarm mapping revolutionizes inventory management by enabling simultaneous, real-time data collection across vast warehouse sections, significantly surpassing the limited reach and slower pace of traditional forklift operations. Leveraging advanced sensors and AI, drone swarms optimize spatial analytics and enhance accuracy in stock tracking, reducing human error and operational costs while increasing inventory visibility.

Forklift-Drone Hybrid Integration

Forklift-drone hybrid integration in warehousing combines the heavy-lifting capacity of forklifts with drones' aerial inventory scanning for enhanced operational efficiency and accuracy. This synergy reduces human error, accelerates stock audits, and optimizes space utilization by leveraging real-time data from drone surveillance alongside forklift material handling.

Real-Time Inventory Scan Automation

Forklift operation relies on manual scanning and physical movement for inventory management, resulting in slower real-time data updates and increased labor costs. Drone inventory management automates real-time inventory scans using advanced sensors and AI, significantly enhancing accuracy and efficiency in warehouse operations.

Collision Avoidance Systems (Forklifts & Drones)

Collision avoidance systems in forklift operation typically use ultrasonic sensors and proximity detection to prevent accidents in confined warehouse spaces, enhancing worker safety and equipment longevity. Drone inventory management incorporates advanced LiDAR and computer vision technologies to navigate complex environments while avoiding collisions, enabling precise stock monitoring and reduced human error.

RFID-Enabled Drone Tracking

RFID-enabled drone tracking revolutionizes warehouse inventory management by providing real-time, accurate data collection that surpasses traditional forklift operation limitations. This technology enhances efficiency, reduces human error, and enables seamless asset tracking in large-scale storage environments.

Forklift Operation vs Drone Inventory Management Infographic

industrydif.com

industrydif.com