Cold storage warehouses maintain low temperatures to preserve perishable goods, ensuring product quality and safety through precise refrigeration systems. Climate-smart warehousing integrates energy-efficient technologies and sustainable practices to minimize environmental impact while protecting sensitive inventory. Choosing between these options depends on the specific storage requirements and sustainability goals of the business.

Table of Comparison

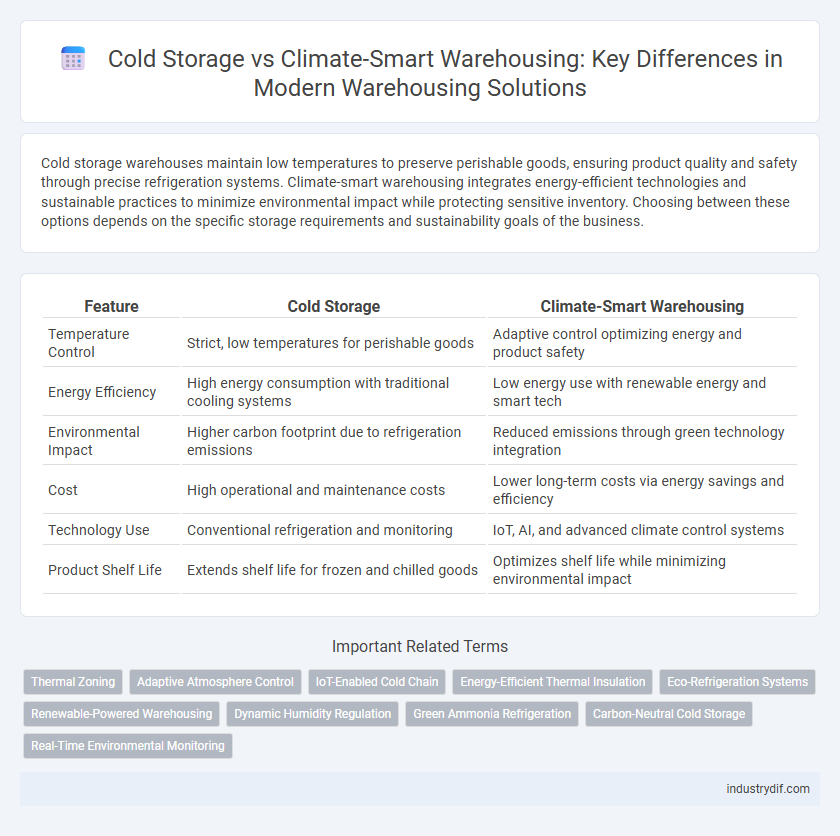

| Feature | Cold Storage | Climate-Smart Warehousing |

|---|---|---|

| Temperature Control | Strict, low temperatures for perishable goods | Adaptive control optimizing energy and product safety |

| Energy Efficiency | High energy consumption with traditional cooling systems | Low energy use with renewable energy and smart tech |

| Environmental Impact | Higher carbon footprint due to refrigeration emissions | Reduced emissions through green technology integration |

| Cost | High operational and maintenance costs | Lower long-term costs via energy savings and efficiency |

| Technology Use | Conventional refrigeration and monitoring | IoT, AI, and advanced climate control systems |

| Product Shelf Life | Extends shelf life for frozen and chilled goods | Optimizes shelf life while minimizing environmental impact |

Understanding Cold Storage: Core Concepts

Cold storage warehouses maintain temperatures typically between -18degC and 5degC to preserve perishable goods such as pharmaceuticals, food products, and chemicals, ensuring product integrity and extending shelf life. These facilities require specialized refrigeration systems, insulation materials, and humidity controls to prevent spoilage and microbial growth. Understanding cold storage involves analyzing temperature zones, energy consumption, and regulatory compliance for optimal inventory management and quality assurance.

Climate-Smart Warehousing: An Overview

Climate-smart warehousing integrates energy-efficient technologies and sustainable practices to reduce carbon footprints and optimize temperature control in storage facilities. Unlike traditional cold storage, which relies heavily on refrigeration, climate-smart warehouses utilize advanced insulation, renewable energy sources, and adaptive climate control systems to maintain product quality while minimizing environmental impact. This approach enhances operational efficiency, reduces costs, and supports supply chain resilience in the face of climate change.

Key Differences Between Cold Storage and Climate-Smart Warehousing

Cold storage facilities maintain consistently low temperatures to preserve perishable goods such as food and pharmaceuticals, emphasizing energy-intensive refrigeration systems. Climate-smart warehousing integrates sustainable practices like energy-efficient insulation, renewable energy use, and adaptive temperature control to minimize environmental impact. Key differences lie in energy consumption patterns, carbon footprint, and the incorporation of eco-friendly technologies aimed at reducing greenhouse gas emissions in climate-smart warehousing.

Temperature Control Technologies

Cold storage warehouses utilize advanced refrigeration systems and insulated environments to maintain temperatures typically below 5degC, ensuring the preservation of perishable goods like food and pharmaceuticals. Climate-smart warehousing integrates adaptive temperature control technologies such as variable-speed compressors, humidity regulators, and energy-efficient HVAC systems to optimize thermal conditions while reducing carbon footprints. Both approaches rely on precise monitoring sensors and automated controls, but climate-smart solutions emphasize sustainability alongside temperature stability.

Energy Efficiency in Modern Warehousing

Cold storage facilities are designed to maintain specific low temperatures, consuming significant energy through refrigeration systems essential for preserving perishable goods. Climate-smart warehousing integrates advanced insulation materials, energy-efficient HVAC systems, and renewable energy sources to optimize temperature control while reducing carbon footprints. Implementing smart sensors and energy management software enhances operational efficiency, lowering electricity consumption and advancing sustainable practices in modern warehousing.

Sustainability Practices in Warehousing

Cold storage facilities prioritize energy-intensive refrigeration systems to preserve perishable goods, often relying on fossil fuels that increase carbon emissions. Climate-smart warehousing integrates renewable energy sources, energy-efficient insulation, and advanced temperature control technologies to reduce environmental impact while maintaining product quality. Sustainable practices in warehousing emphasize minimizing energy consumption, reducing greenhouse gas emissions, and adopting circular economy principles to enhance overall operational efficiency.

Cost Implications: Cold Storage vs Climate-Smart Solutions

Cold storage warehouses typically require high energy consumption for refrigeration, resulting in substantial operational costs and increased carbon footprints. Climate-smart warehousing integrates energy-efficient technologies and renewable energy sources, leading to significant long-term cost savings and reduced environmental impact. Investment in climate-smart solutions can offset initial expenses through decreased utility bills and potential government incentives for sustainable practices.

Regulatory Compliance and Standards

Cold storage facilities must adhere to stringent regulatory requirements such as FDA's Food Safety Modernization Act (FSMA) and ISO 22000 to ensure safe temperature control and prevent food spoilage. Climate-smart warehousing incorporates advanced environmental management standards, including ISO 14001, to minimize carbon emissions and optimize energy efficiency while also maintaining compliance with evolving local and international sustainability regulations. Both approaches demand rigorous documentation, regular audits, and real-time monitoring systems to meet compliance standards and guarantee product integrity throughout the supply chain.

Industry Applications and Use Cases

Cold storage facilities are essential in industries such as pharmaceuticals, food and beverage, and biotechnology, where maintaining low temperatures preserves product integrity and extends shelf life. Climate-smart warehousing integrates energy-efficient technologies and sustainable practices, benefiting sectors like electronics, apparel, and green supply chains by optimizing storage conditions while reducing carbon footprints. These approaches address specific industry needs: cold storage emphasizes strict temperature control for perishable goods, whereas climate-smart warehousing focuses on environmental impact and operational efficiency across diverse product categories.

Future Trends in Cold and Climate-Smart Warehousing

Future trends in cold and climate-smart warehousing emphasize the integration of advanced IoT sensors and AI-driven energy management systems to optimize temperature control and reduce carbon footprints. Innovations in renewable energy-powered refrigeration and improved insulation materials are set to enhance efficiency and sustainability. Embracing these technologies will enable warehouses to meet stricter environmental regulations while ensuring product quality and reducing operational costs.

Related Important Terms

Thermal Zoning

Cold storage facilities maintain subzero temperatures for perishable goods, utilizing insulated thermal zones to prevent temperature fluctuations and ensure product integrity. Climate-smart warehousing incorporates adaptive thermal zoning strategies that optimize energy use while accommodating varying temperature-sensitive products within a single facility.

Adaptive Atmosphere Control

Adaptive Atmosphere Control in cold storage optimizes temperature, humidity, and gas composition to prolong shelf life and maintain product quality, especially for perishable goods like fruits and pharmaceuticals. Climate-smart warehousing integrates this technology with energy-efficient systems and renewable energy sources to reduce carbon footprints while ensuring precise atmospheric conditions.

IoT-Enabled Cold Chain

IoT-enabled cold chain systems integrate real-time temperature monitoring, humidity control, and predictive analytics to enhance cold storage efficiency and reduce spoilage in warehousing. Climate-smart warehousing leverages these IoT technologies to optimize energy consumption while maintaining precise environmental conditions, ensuring product quality and sustainability.

Energy-Efficient Thermal Insulation

Energy-efficient thermal insulation in cold storage facilities minimizes heat transfer to maintain consistent low temperatures, significantly reducing refrigeration energy consumption and operational costs. Climate-smart warehousing integrates advanced insulation materials with adaptive energy management systems to optimize thermal performance while supporting sustainability goals and reducing carbon footprints.

Eco-Refrigeration Systems

Eco-refrigeration systems in cold storage warehouses utilize natural refrigerants like ammonia and CO2, significantly reducing greenhouse gas emissions compared to conventional HFC-based cooling methods. Climate-smart warehousing integrates these eco-friendly technologies with energy-efficient insulation and real-time environmental monitoring, optimizing temperature control while minimizing carbon footprints and operational costs.

Renewable-Powered Warehousing

Renewable-powered warehousing integrates solar, wind, and geothermal energy systems to optimize cold storage facilities by significantly reducing carbon footprints and operational costs. Climate-smart warehousing enhances energy efficiency through smart temperature controls and sustainable building designs, supporting eco-friendly cold chain logistics while maintaining product integrity.

Dynamic Humidity Regulation

Cold storage facilities maintain fixed low temperatures ideal for perishable goods, while climate-smart warehousing incorporates dynamic humidity regulation to optimize storage conditions for a broader range of products. Utilizing advanced sensors and automated controls, dynamic humidity regulation minimizes spoilage and energy consumption by adjusting moisture levels in real-time based on environmental and inventory data.

Green Ammonia Refrigeration

Green ammonia refrigeration offers a sustainable alternative for cold storage facilities by significantly reducing greenhouse gas emissions through the use of ammonia as a natural refrigerant with zero global warming potential. Climate-smart warehousing integrates green ammonia systems to enhance energy efficiency, lower operational costs, and support environmental compliance, setting new standards for eco-friendly cold storage solutions.

Carbon-Neutral Cold Storage

Carbon-neutral cold storage facilities integrate advanced insulation technology and renewable energy sources such as solar panels and geothermal systems to drastically reduce greenhouse gas emissions. These climate-smart warehouses optimize temperature control while minimizing energy consumption, setting new standards for sustainable supply chain management in temperature-sensitive warehousing.

Real-Time Environmental Monitoring

Real-time environmental monitoring in cold storage facilities ensures precise temperature and humidity control, critical for preserving perishable goods and preventing spoilage. Climate-smart warehousing integrates sensor technologies and IoT to continuously track and adjust environmental conditions, enhancing energy efficiency and sustainability while maintaining optimal storage environments.

Cold Storage vs Climate-Smart Warehousing Infographic

industrydif.com

industrydif.com