Inventory management focuses on efficiently tracking and storing products within large warehouses to optimize stock levels and reduce holding costs. Micro-fulfillment centers prioritize rapid order processing by locating inventory closer to consumers, enabling faster delivery and enhancing customer satisfaction. Combining inventory management with micro-fulfillment strategies improves overall supply chain agility and responsiveness.

Table of Comparison

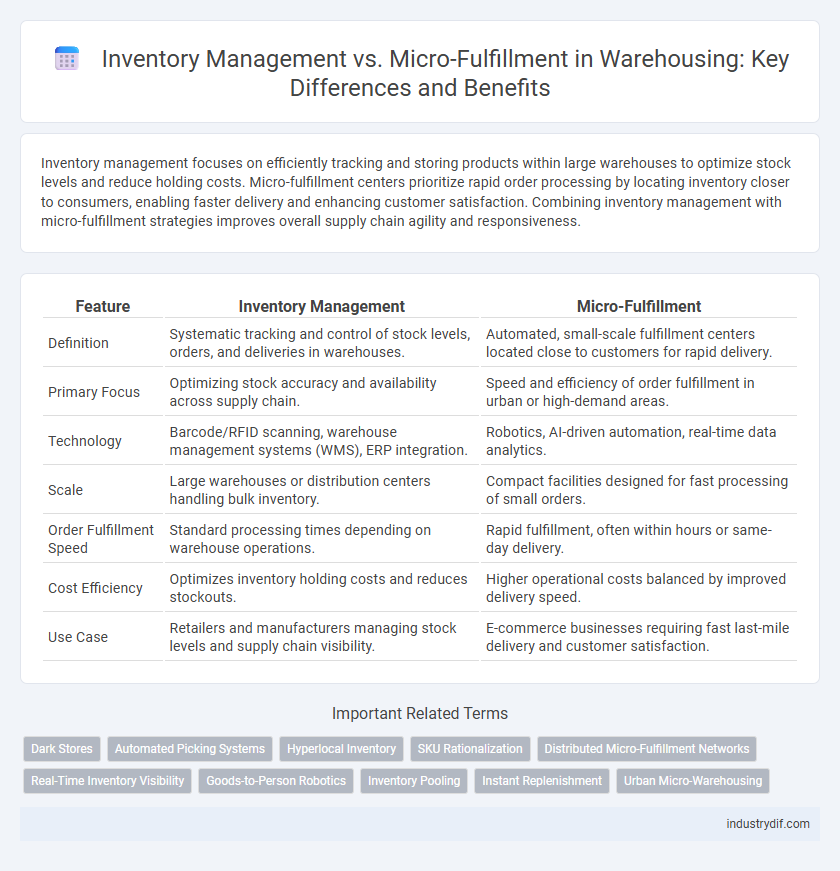

| Feature | Inventory Management | Micro-Fulfillment |

|---|---|---|

| Definition | Systematic tracking and control of stock levels, orders, and deliveries in warehouses. | Automated, small-scale fulfillment centers located close to customers for rapid delivery. |

| Primary Focus | Optimizing stock accuracy and availability across supply chain. | Speed and efficiency of order fulfillment in urban or high-demand areas. |

| Technology | Barcode/RFID scanning, warehouse management systems (WMS), ERP integration. | Robotics, AI-driven automation, real-time data analytics. |

| Scale | Large warehouses or distribution centers handling bulk inventory. | Compact facilities designed for fast processing of small orders. |

| Order Fulfillment Speed | Standard processing times depending on warehouse operations. | Rapid fulfillment, often within hours or same-day delivery. |

| Cost Efficiency | Optimizes inventory holding costs and reduces stockouts. | Higher operational costs balanced by improved delivery speed. |

| Use Case | Retailers and manufacturers managing stock levels and supply chain visibility. | E-commerce businesses requiring fast last-mile delivery and customer satisfaction. |

Introduction to Inventory Management and Micro-Fulfillment

Inventory management involves tracking and controlling stock levels, locations, and orders to optimize supply chain efficiency and reduce holding costs. Micro-fulfillment centers utilize automated technology within small-scale warehouses near urban areas to enable rapid order processing and delivery. Integrating micro-fulfillment strategies with inventory management enhances accuracy and responsiveness in high-demand retail environments.

Defining Inventory Management in Modern Warehousing

Inventory management in modern warehousing involves the systematic tracking, organizing, and controlling of stock levels to optimize supply chain efficiency and reduce holding costs. It integrates advanced software solutions and real-time data analytics to ensure accurate demand forecasting and timely replenishment. Unlike micro-fulfillment centers, which prioritize rapid order fulfillment in small, localized spaces, inventory management provides a comprehensive overview of stock status across multiple distribution points.

What Is Micro-Fulfillment? Key Concepts Explained

Micro-fulfillment is a strategic approach within warehousing that uses small, automated fulfillment centers located close to the end customer to accelerate order processing and delivery times. Unlike traditional inventory management focused on large centralized warehouses, micro-fulfillment integrates advanced robotics, real-time inventory tracking, and data-driven demand forecasting to optimize last-mile logistics. This model enhances supply chain efficiency by reducing transit distance, minimizing inventory holding costs, and enabling rapid response to consumer demand fluctuations.

Core Differences Between Inventory Management and Micro-Fulfillment

Inventory management centers on tracking stock levels, optimizing reorder points, and maintaining accurate records to ensure product availability and reduce holding costs. Micro-fulfillment focuses on rapid order processing within compact, automated warehouse systems designed to accelerate last-mile delivery and enhance customer satisfaction. The core difference lies in inventory management optimizing stock control across the supply chain, while micro-fulfillment prioritizes speed and efficiency in order fulfillment through localized, technology-driven solutions.

The Role of Automation in Inventory Management vs Micro-Fulfillment

Automation in inventory management streamlines stock tracking and demand forecasting using RFID, barcode scanning, and AI-driven analytics, reducing human error and optimizing order accuracy. In micro-fulfillment, automation accelerates picking, packing, and sorting processes through robotics and conveyor systems, enabling faster order turnaround in limited urban spaces. Both systems leverage automation to enhance efficiency, but micro-fulfillment prioritizes speed and spatial optimization, while inventory management focuses on accuracy and stock visibility across the supply chain.

Impact on Order Accuracy and Speed

Inventory management systems optimize stock control through real-time tracking and demand forecasting, enhancing order accuracy by reducing stockouts and overstock situations. Micro-fulfillment centers prioritize rapid order processing and localized storage, significantly boosting speed by minimizing last-mile delivery times. Both approaches improve customer satisfaction but balance order accuracy and fulfillment speed differently depending on operational priorities.

Inventory Optimization Strategies for Warehousing

Inventory optimization strategies in warehousing leverage advanced data analytics and real-time tracking to balance stock levels effectively, minimizing holding costs while ensuring product availability. Micro-fulfillment centers employ localized, automated systems that enhance inventory turnover and reduce delivery times by storing products closer to end consumers. Integrating micro-fulfillment with inventory management enables dynamic stock replenishment and precise demand forecasting, driving operational efficiency and improved customer satisfaction.

Space Utilization: Traditional Warehousing vs Micro-Fulfillment Centers

Traditional warehousing emphasizes bulk storage with extensive space to accommodate large inventories, often resulting in underutilized areas due to inflexible layouts. Micro-fulfillment centers optimize space by integrating automated systems and vertical storage, maximizing cubic footage and increasing throughput within smaller footprints. Efficient space utilization in micro-fulfillment drives faster order processing and reduces costs compared to conventional warehouse models.

Costs and Scalability: Comparing the Two Approaches

Inventory management systems optimize storage costs by accurately tracking stock levels and reducing excess inventory, leading to lower holding expenses. Micro-fulfillment centers prioritize rapid order fulfillment with smaller, automated facilities, which can increase initial capital expenditure but offer scalable solutions in high-demand urban areas. Companies must balance the lower operational costs of traditional inventory management against the scalability and speed advantages provided by micro-fulfillment to meet evolving consumer expectations.

Choosing the Right Solution for Your Warehousing Needs

Effective inventory management ensures accurate stock tracking and reduces holding costs, while micro-fulfillment focuses on rapid order processing in localized facilities to meet same-day delivery demands. Selecting the right solution depends on factors such as order volume, storage space, and customer proximity, with micro-fulfillment systems excelling in urban environments offering fast delivery. Warehouses prioritizing large-scale storage and long-term stock control benefit more from traditional inventory management systems tailored to optimize supply chain efficiency.

Related Important Terms

Dark Stores

Dark stores optimize micro-fulfillment by transforming traditional inventory management into streamlined, localized hubs that accelerate order processing and reduce delivery times. Leveraging real-time inventory tracking and automated picking systems, dark stores enhance efficiency in urban warehousing, meeting rising e-commerce demands with precision.

Automated Picking Systems

Automated picking systems in inventory management enhance efficiency by reducing human error and accelerating order processing in large warehouses. Micro-fulfillment centers leverage these systems for compact, high-speed order fulfillment, optimizing space and enabling rapid delivery in urban environments.

Hyperlocal Inventory

Hyperlocal inventory integrates micro-fulfillment centers with advanced inventory management systems to optimize stock levels near end consumers, reducing delivery times and transportation costs. Enhanced demand forecasting and real-time inventory tracking in hyperlocal setups enable precise order fulfillment, improving customer satisfaction and operational efficiency in urban warehousing.

SKU Rationalization

SKU rationalization plays a critical role in inventory management by streamlining stock-keeping units to reduce holding costs and improve order accuracy. In micro-fulfillment centers, effective SKU rationalization enhances space utilization and accelerates picking processes, driving faster delivery times and increased operational efficiency.

Distributed Micro-Fulfillment Networks

Distributed micro-fulfillment networks enhance inventory management by decentralizing stock closer to demand points, reducing lead times and improving order accuracy in urban areas. Integrating real-time inventory tracking with localized micro-fulfillment centers optimizes space utilization and accelerates delivery, driving operational efficiency in e-commerce logistics.

Real-Time Inventory Visibility

Real-time inventory visibility enhances micro-fulfillment by providing precise stock levels and location data, enabling faster order processing and reduced fulfillment errors. Advanced inventory management systems integrate seamlessly with micro-fulfillment technologies to synchronize stock updates, optimize replenishment, and meet demand with greater accuracy.

Goods-to-Person Robotics

Goods-to-person robotics revolutionize inventory management by automating the retrieval and delivery of items, significantly increasing efficiency and accuracy in micro-fulfillment centers. This technology minimizes human labor, reduces picking errors, and accelerates order processing, enabling faster turnaround times and optimized use of warehouse space.

Inventory Pooling

Inventory pooling in warehousing optimizes stock distribution by consolidating inventory across multiple locations, enhancing Micro-Fulfillment efficiency through reduced delivery times and lower holding costs. Effective inventory management leverages real-time data analytics and automated replenishment systems to maintain optimal stock levels, ensuring seamless order fulfillment and minimizing stockouts in micro-fulfillment centers.

Instant Replenishment

Inventory management in warehousing ensures accurate stock levels and reduces holding costs through continuous monitoring, while micro-fulfillment centers leverage real-time data and automation to enable instant replenishment and faster order fulfillment, enhancing supply chain responsiveness and customer satisfaction. Integrating micro-fulfillment with advanced inventory management systems optimizes stock distribution, minimizes delays, and supports dynamic demand-driven restocking.

Urban Micro-Warehousing

Urban micro-warehousing enhances inventory management by enabling rapid stock replenishment through strategically located small-scale warehouses, reducing delivery times and transportation costs in dense city areas. This micro-fulfillment approach leverages real-time inventory tracking and automation technologies to optimize stock levels and meet high consumer demand near urban centers efficiently.

Inventory Management vs Micro-Fulfillment Infographic

industrydif.com

industrydif.com