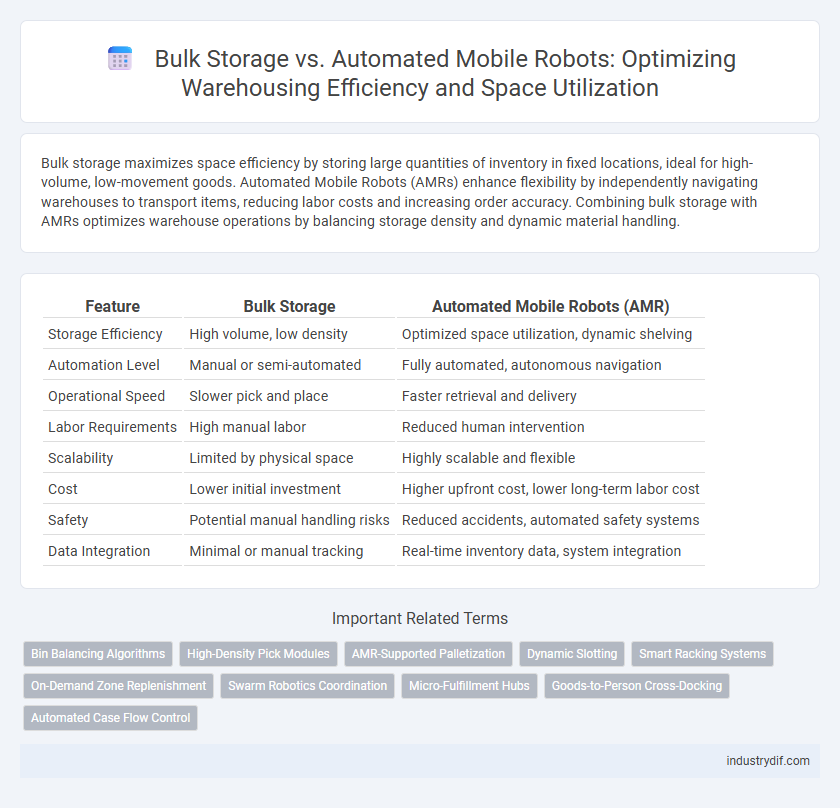

Bulk storage maximizes space efficiency by storing large quantities of inventory in fixed locations, ideal for high-volume, low-movement goods. Automated Mobile Robots (AMRs) enhance flexibility by independently navigating warehouses to transport items, reducing labor costs and increasing order accuracy. Combining bulk storage with AMRs optimizes warehouse operations by balancing storage density and dynamic material handling.

Table of Comparison

| Feature | Bulk Storage | Automated Mobile Robots (AMR) |

|---|---|---|

| Storage Efficiency | High volume, low density | Optimized space utilization, dynamic shelving |

| Automation Level | Manual or semi-automated | Fully automated, autonomous navigation |

| Operational Speed | Slower pick and place | Faster retrieval and delivery |

| Labor Requirements | High manual labor | Reduced human intervention |

| Scalability | Limited by physical space | Highly scalable and flexible |

| Cost | Lower initial investment | Higher upfront cost, lower long-term labor cost |

| Safety | Potential manual handling risks | Reduced accidents, automated safety systems |

| Data Integration | Minimal or manual tracking | Real-time inventory data, system integration |

Introduction to Bulk Storage and Automated Mobile Robots

Bulk storage in warehousing involves storing large quantities of homogeneous goods in designated areas, maximizing space utilization through methods like pallet stacking and container storage. Automated Mobile Robots (AMRs) enhance warehouse efficiency by autonomously navigating and transporting inventory, reducing labor costs and increasing operational speed. Integrating bulk storage with AMRs enables seamless inventory management and faster order fulfillment in modern warehouses.

Key Differences Between Bulk Storage and AMRs

Bulk storage systems primarily handle large quantities of uniform goods stored in fixed locations, maximizing space efficiency without real-time inventory tracking. Automated Mobile Robots (AMRs) offer dynamic material handling by navigating warehouse floors autonomously, enabling flexible transport and precise inventory management. The key differences lie in bulk storage's focus on static, high-density storage versus AMRs' adaptability, speed, and integration with warehouse management systems for optimized workflow.

Efficiency and Space Utilization

Bulk storage systems maximize space utilization by stacking large quantities of inventory in dense configurations, reducing the footprint required for warehouse operations. Automated mobile robots (AMRs) enhance efficiency by dynamically navigating warehouse layouts to retrieve and transport items, minimizing human labor and improving order fulfillment speed. Integrating AMRs with bulk storage solutions optimizes overall warehouse performance by combining high-density storage with agile, automated material handling.

Cost Implications and ROI Comparison

Bulk storage systems require lower initial capital investment but incur higher operational costs due to manual labor and slower inventory handling. Automated Mobile Robots (AMRs) demand significant upfront expenditure in technology and integration but deliver faster throughput, reduced labor costs, and improved accuracy, enhancing long-term ROI. Companies evaluating warehousing solutions must consider the balance between upfront costs and operational efficiency to determine the most cost-effective option based on their volume and velocity of inventory.

Flexibility and Scalability in Warehousing

Bulk storage systems provide high-density inventory management but often lack flexibility in reconfiguring space or adjusting to fluctuating demand. Automated Mobile Robots (AMRs) offer dynamic scalability by easily adapting to changing warehouse layouts and variable throughput requirements without major infrastructure changes. The integration of AMRs enhances operational flexibility, enabling real-time responsiveness and efficient utilization of storage capacity in modern warehousing environments.

Labor Requirements and Workforce Impact

Bulk storage significantly reduces labor requirements by minimizing manual handling and optimizing space utilization, leading to fewer workers needed for inventory management. Automated Mobile Robots (AMRs) further enhance efficiency by automating item retrieval and transport, decreasing labor dependency and reallocating workforce to higher-value tasks. The adoption of AMRs transforms the workforce by demanding advanced technical skills for robot maintenance and supervision, shifting labor focus from physical tasks to operational management.

Inventory Management and Accuracy

Bulk storage enables the handling of large quantities of inventory but often faces challenges in real-time accuracy and efficient stock tracking. Automated Mobile Robots (AMRs) enhance inventory management by providing precise real-time data updates and reducing human error through automated scanning and retrieval systems. Integrating AMRs in warehousing significantly improves inventory accuracy and operational efficiency compared to traditional bulk storage methods.

Safety Considerations for Each Solution

Bulk storage systems reduce safety risks by minimizing the need for forklift operations in tightly packed areas but require rigorous stacking protocols to prevent collapses and ensure structural stability. Automated Mobile Robots (AMRs) enhance workplace safety by eliminating heavy human labor and reducing collision hazards through advanced sensors and real-time navigation, yet demand robust cybersecurity measures to prevent operational disruptions. Both solutions necessitate comprehensive training programs and ongoing maintenance to uphold safety standards and mitigate potential accidents in warehousing environments.

Implementation Challenges and Best Practices

Bulk storage systems require significant space allocation and structural reinforcement, posing challenges in facility layout and scalability. Automated Mobile Robots (AMRs) demand advanced integration with warehouse management systems and continuous maintenance to ensure operational efficiency. Best practices include phased implementation, comprehensive staff training, and leveraging data analytics to optimize both bulk storage capacity and AMR routing.

Future Trends in Warehousing Automation

Future trends in warehousing automation emphasize the integration of Automated Mobile Robots (AMRs) over traditional bulk storage methods due to their enhanced flexibility, scalability, and efficiency in inventory management. AMRs enable real-time data analytics and dynamic task allocation, significantly reducing labor costs and improving order accuracy compared to static bulk storage systems. The shift towards AI-driven robotics and IoT connectivity is expected to revolutionize warehouse operations, optimizing space utilization and accelerating fulfillment processes.

Related Important Terms

Bin Balancing Algorithms

Bin balancing algorithms optimize the distribution of inventory across storage bins to maximize space utilization and minimize retrieval time in both bulk storage and automated mobile robot systems. In bulk storage, these algorithms enhance manual picking efficiency, while in automated mobile robots, they dynamically allocate bins to robot paths, improving overall throughput and reducing idle time.

High-Density Pick Modules

High-density pick modules maximize storage capacity by utilizing vertical space and automated shelving systems, significantly reducing aisle widths compared to bulk storage. Automated Mobile Robots (AMRs) enhance efficiency in these modules by dynamically transporting goods within the warehouse, increasing throughput and minimizing human labor in dense storage environments.

AMR-Supported Palletization

AMR-supported palletization enhances bulk storage efficiency by automating the handling and organization of pallets, reducing labor costs and minimizing errors. Automated Mobile Robots (AMRs) improve space utilization and throughput in warehouses by dynamically navigating storage areas, optimizing pallet placement, and enabling real-time inventory tracking.

Dynamic Slotting

Dynamic slotting significantly enhances warehousing efficiency by using Automated Mobile Robots (AMRs) to adaptively organize bulk storage based on real-time inventory flows and demand patterns. This automation reduces manual labor, optimizes space utilization, and accelerates pick-and-place operations compared to traditional static bulk storage methods.

Smart Racking Systems

Smart racking systems enhance bulk storage by maximizing vertical space utilization and enabling seamless integration with Automated Mobile Robots (AMRs) to optimize inventory access and retrieval speed. These intelligent storage solutions leverage real-time data and robotics coordination to improve warehouse efficiency, reduce labor costs, and support scalable, flexible operations.

On-Demand Zone Replenishment

Bulk storage systems prioritize high-density inventory holding, enabling efficient space utilization but often require manual zone replenishment that can delay order fulfillment. Automated Mobile Robots (AMRs) enhance on-demand zone replenishment by dynamically transporting goods to picking areas, reducing downtime and increasing operational throughput in warehouses.

Swarm Robotics Coordination

Bulk storage systems optimize space by storing large quantities of uniform goods efficiently, but lack dynamic flexibility in retrieval processes. Swarm robotics coordination in automated mobile robots enhances warehouse operations by enabling decentralized, scalable, and adaptive task execution, improving inventory handling speed and accuracy in complex environments.

Micro-Fulfillment Hubs

Bulk storage systems maximize space utilization for high-volume inventory in micro-fulfillment hubs, enabling efficient handling of large quantities of homogeneous products. Automated mobile robots enhance operational flexibility and speed by dynamically transporting goods, reducing labor costs, and optimizing order accuracy within compact fulfillment environments.

Goods-to-Person Cross-Docking

Bulk storage maximizes warehouse capacity by storing large quantities of goods in a fixed location, while Automated Mobile Robots (AMRs) enhance efficiency in Goods-to-Person cross-docking by dynamically transporting products directly to picking stations, reducing manual handling and speeding up order fulfillment. Integrating AMRs in cross-docking operations optimizes inventory flow, minimizes storage requirements, and supports just-in-time distribution in high-throughput warehouses.

Automated Case Flow Control

Automated Case Flow Control leverages Automated Mobile Robots (AMRs) to enhance precision and efficiency in bulk storage management by dynamically directing case movements and optimizing inventory flow. This technology reduces manual errors and accelerates order fulfillment cycles, outperforming traditional bulk storage systems through real-time data integration and adaptive routing algorithms.

Bulk Storage vs Automated Mobile Robots Infographic

industrydif.com

industrydif.com